Auxiliary contact set-up procedure – Rockwell Automation 1502 Medium Voltage 400A Contactor - Series E User Manual

Page 44

44

Rockwell Automation Publication 1502-UM052H-EN-P - June 2013

Chapter 4

Maintenance

6. Install the armature plate, auxiliary actuator and stop bracket. Position the

stop bracket by resting it lightly against the armature plate.

Auxiliary Contact Set-up

Procedure

Refer to Chapter 6 for part number(s) required for this procedure.

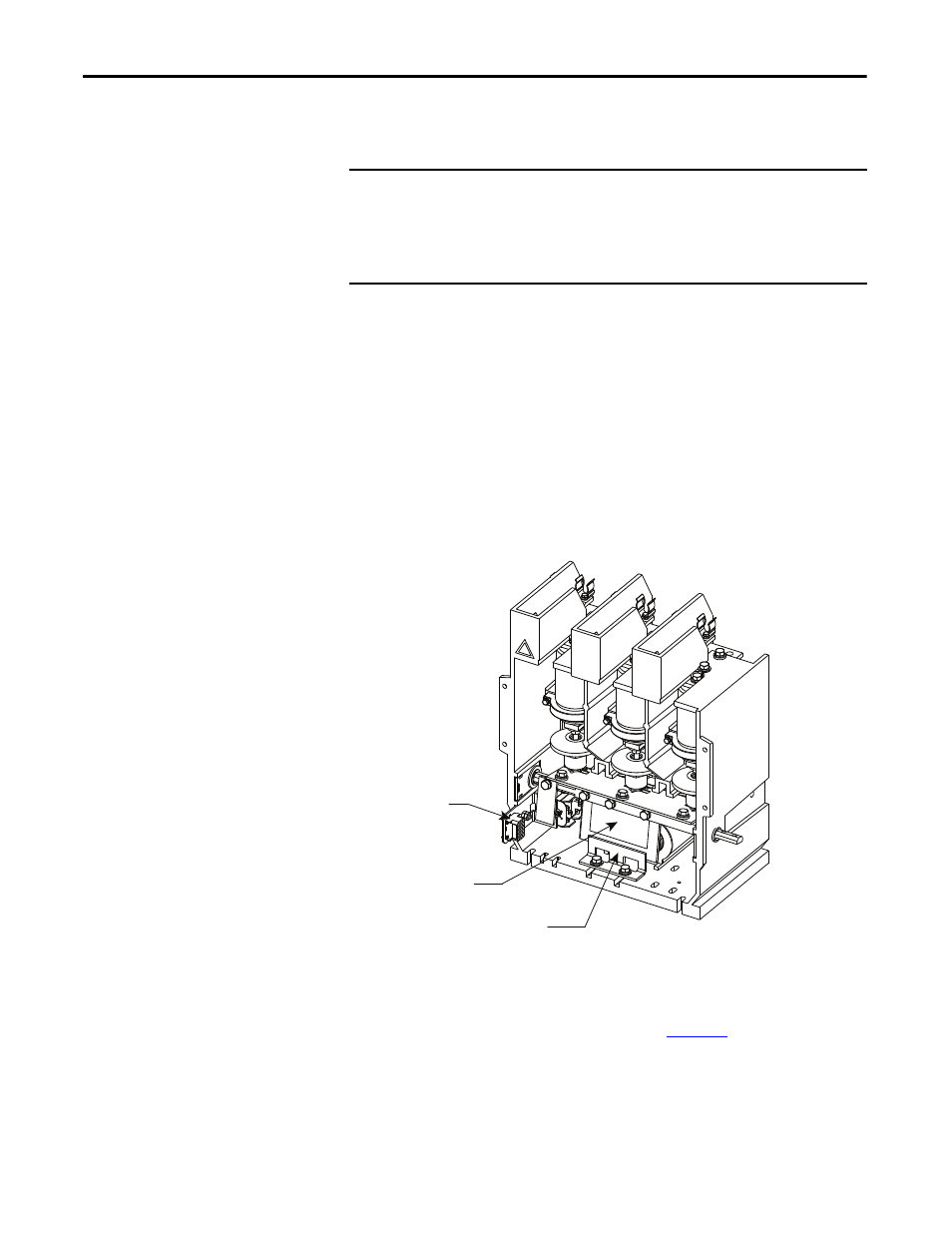

To facilitate the set-up procedure, the contactor is held closed mechanically by

means of a clamping fixture as shown in Figure 4.13. It is important that the

contactor is held closed tightly with the armature plate against the magnet cores

when gauging the overtravel and auxiliary positioning.

To aid in closing the contactor mechanically, a clamping fixture is required. Allen-

Bradley part number

80154-149-51 is recommended.

Figure 35 - Contactor Components

1. Loosen the nuts on auxiliary assembly retaining bolt. This requires

loosening and removal of the first nut which secures a ground wire at this

location. Leave on nut loosened just enough to permit the assembly to

slide along the adjustment slot as shown in

.

IMPORTANT

This procedure applies to adjustment of existing auxiliaries and installation of

new auxiliaries. Under normal conditions, auxiliaries will last at least

1,000,000 operations. If auxiliary contacts must be replaced, discard the entire

assembly and install a new assembly. This is easier than replacing a single

contact block.

Auxiliary Actuator

Armature Plate

Armature Stop Bracket