Vacuum bottle replacement and set-up procedure, Figure 26 – Rockwell Automation 1502 Medium Voltage 400A Contactor - Series E User Manual

Page 38

38

Rockwell Automation Publication 1502-UM052H-EN-P - June 2013

Chapter 4

Maintenance

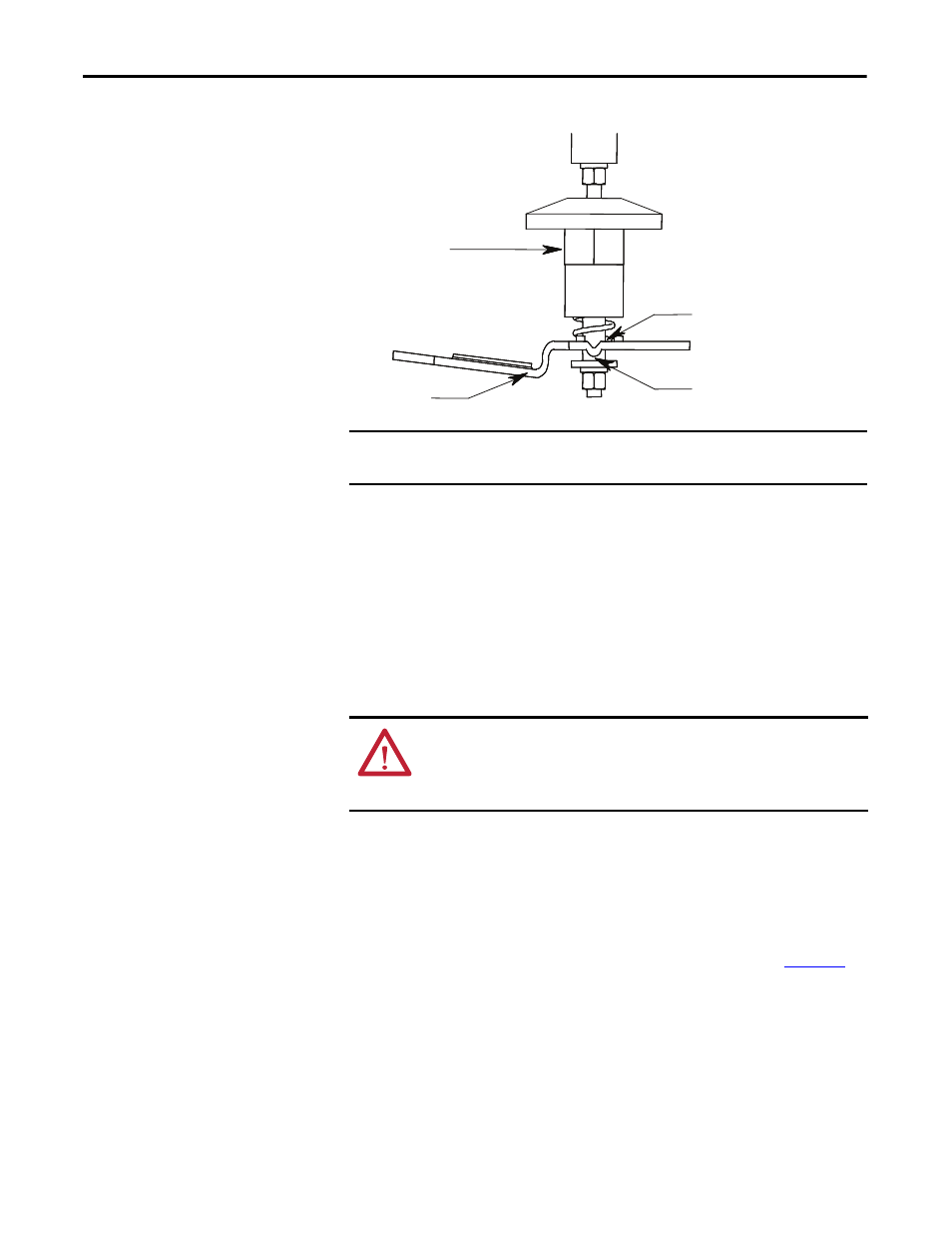

Figure 26 - Grease Locations

Vacuum Bottle Replacement

and Set-Up Procedure

Under normal conditions, vacuum bottles will last at least 1,000,000 operations;

however, all three bottles must be replaced if any wear indicator line reaches the

bearing (regardless of the number of operations). Refer to FIX THIS or the part

number(s) required for this procedure.

Use the following procedure to remove and replace the vacuum bottles. This

procedure can be performed with the contactor remaining in the power cell of

the controller.

1. Before removing the vacuum bottles, mark the installed bottles clearly to

avoid confusing them with the replacement vacuum bottles.

2. If the contactor has not been removed from the starter, first remove the

lower terminal connections at the rear of the contactor.

3. Remove the load terminal retaining bolt at the rear of the contactor, and

the vacuum bottle mounting bolt at the top of the contactor (

IMPORTANT

Do not grease the armature shaft plastic bearings. These bearings are self-

lubricating and do not require grease.

Insulator

Grease

Actuator Plates

Grease

ATTENTION: To avoid shock hazards, lock out incoming power and disconnect

the control plus from the contactor before working on the unit. Verify with a hot

stick or meter that all circuits are voltage free. Failure to do so may result in

severe burns, injury or death