Torque specifications, Scr module access, I-33 – Rockwell Automation 1336S, 1336F, 1336E, 1336T, 1336-SN-SP18A Snubber Board Kit User Manual

Page 33

1336-5.39 – August, 1999

I-33

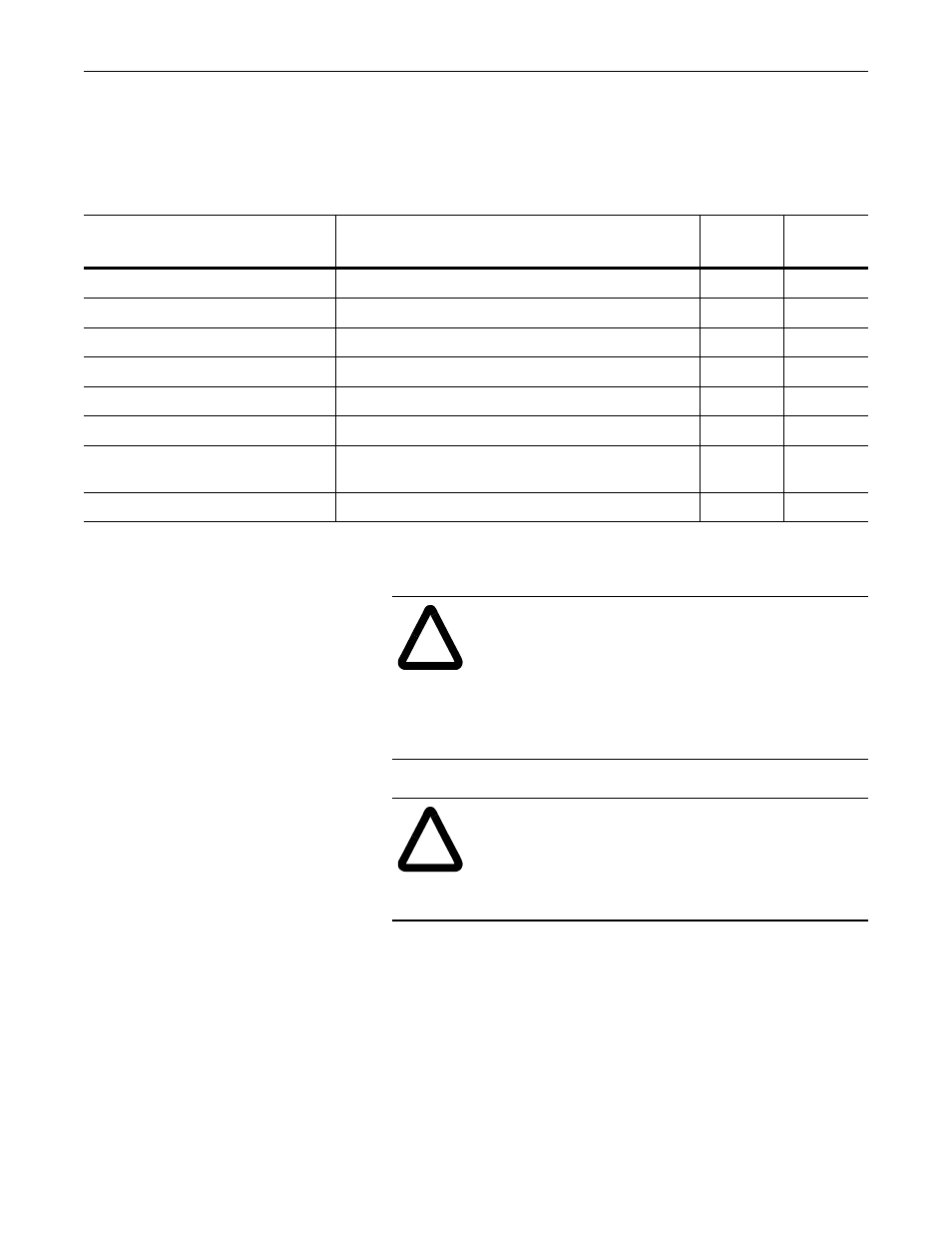

Torque Specifications

The following table lists fastener locations by component,

application, and torque specifications. Refer to “Torque Sequence” on

page I-4 for fastening two-point, four-point, and six-point

components to the heat sink.

SCR Module Access

Important: Before you remove connections and wires from the drive

components, mark the connections and wires to correspond with their

component connections and terminals to prevent incorrect wiring

during assembly.

Component

Fastener Application

Torque

lb-in.

Torque

N-m

Snubber Board

Board to SCR Module

50

6

SCR Module

Module to heat sink

50

6

Wires (PE)

Wires to Ground Stud

80

9

Wires

Wires to TB1

80

9

Wire (TE)

Wire to TB1

50

6

Wires

Wires to TB3

8 – 10

0.9 – 1.13

Main Control, Gate Driver, Precharge

Board Mounting Plates

Plates to chassis

26

3

High Voltage Guard

Guard to chassis

26

3

!

ATTENTION: Disconnect and lock out power from

the drive before disassembling the drive. Failure to

disconnect power may result in death or serious injury.

Verify bus voltage by measuring the voltage between

+DC and -DC on Terminal Block TB1. Do not attempt

to service the drive until the bus voltage has discharged

to zero volts.

!

ATTENTION: Wear a wrist-type grounding strap

when servicing drives. Failure to protect drive

components against ESD may damage drive

components. Refer to “Electrostatic Discharge

Precautions” on page I-4.