Motor fla requirements, Figure 9 - fla setting of motor, Motor overload trip curves – Rockwell Automation 150-E SMC Elevator Users Manual User Manual

Page 21: Figure 10 - trip class

Rockwell Automation Publication 150-UM009D-EN-P- February 2011

21

Programming Chapter 3

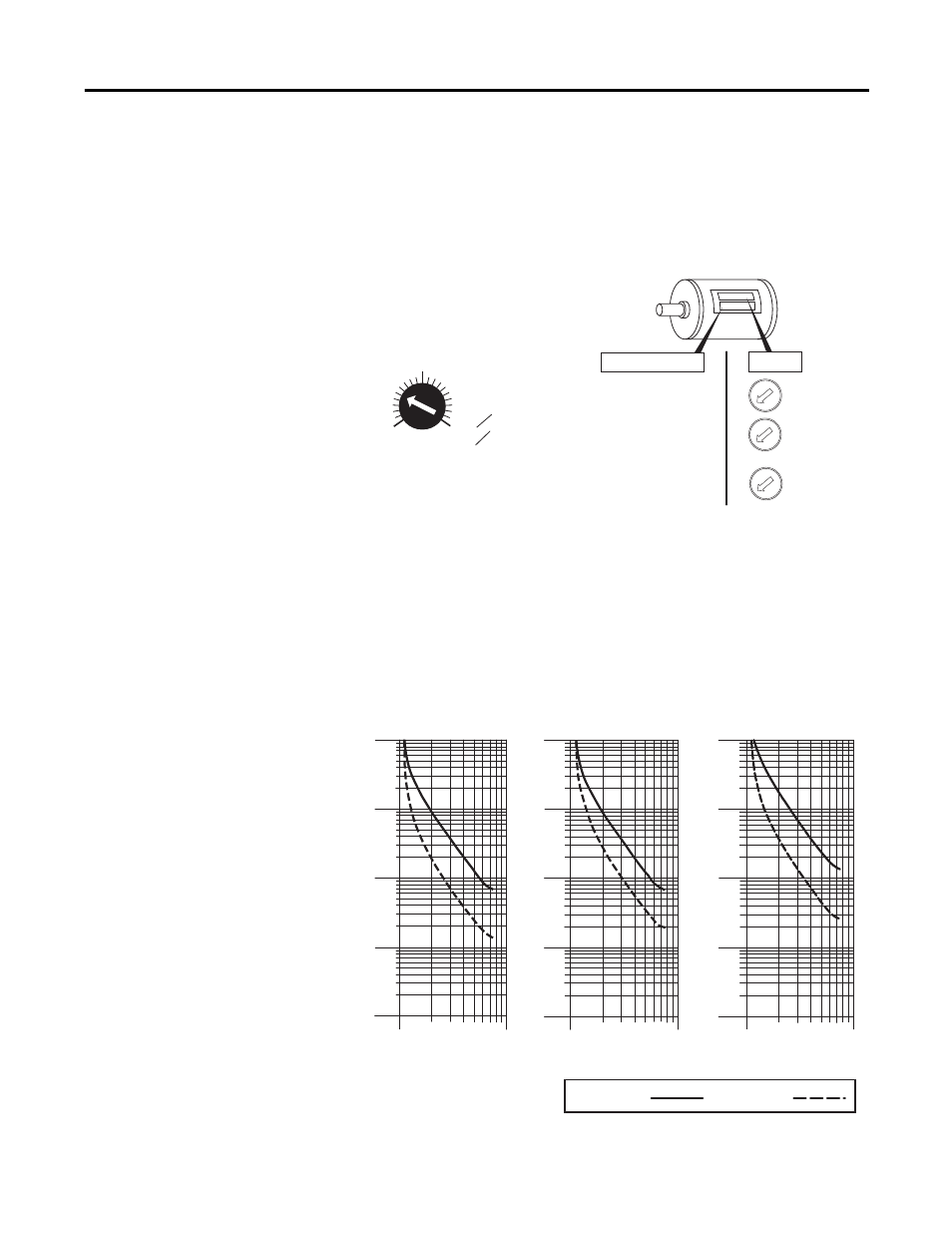

Motor FLA Requirements

The front of the SMC controller contains a dial which is used for setting the

actual FLA of the motor. The label is designed to accommodate motors

connected in the LINE or DELTA mode. To determine the proper setting, look

at the motor’s nameplate and set the dial accordingly. The dial setting can be

modified depending on the service factor of the motor.

Figure 9 - FLA Setting of Motor

Motor Overload Trip Curves

The trip class should be set according to the motor’s maximum permissible locked

rotor time or the general thermal capabilities. Consult the motor manufacturer

for recommendations on setting the trip class.

Figure 10 - Trip Class

∆ 32

19

Delta FLA

Line FLA

∆ 11

7

∆ 22

13

Service Factor _ _

FLA _ _

Service Factor < 1.15

Service Factor ≥ 1.15

= 0.9 X FLA

= 1.0 X FLA

= 1.0 X FLA

OR

Maximum Continuous Rated

(MCR) Motors

Class 10

Class 15

Class 20

Multiple of FLA

t (sec)

8

10

6

4

2

1

1000

100

10

1

0.1

800

600

400

200

80

60

40

20

8

6

4

2

0.2

0.4

0.6

0.8

8

10

6

4

2

1

8

10

6

4

2

1

1000

100

10

1

0.1

800

600

400

200

80

60

40

20

8

6

4

2

0.2

0.4

0.6

0.8

1000

100

10

1

0.1

800

600

400

200

80

60

40

20

8

6

4

2

0.2

0.4

0.6

0.8

COLD START

HOT START