Before using this unit, Installation procedure – Yamato Scientific BB600 Low Constant Temperature Water Bath User Manual

Page 11

8

Before Using This Unit

Installation Procedure

6

Precautions about the circulating path

• Carefully check the direction of circulation, and connect the hoses properly. Improper

connection results in an accident or malfunction of the unit and the circulating path.

• Minimize the length of the circulating path. If resistance inside the piping increases, the quantity

of circulating fluid decreases, resulting in lower cooling efficiency. For the capacity of the

circulating pump, see "Cooling curve, cooling capacity curve (reference data)" on page 39.

• Be sure to connect for making a circulating route. Do not connect with water service or gas

pipe, etc. It may cause an accident or a failure.

• Check the circulation capacity and withstand pressure of the circulating path. Excessive

circulation or pressure may result in an accident or malfunction.

• Do not connect any powered unit or a unit with a motor to the circulating path. It may cause an

accident or failure.

• When changing flux, execute the operation slowly. A rapid change of flux may damage the

durability of the pump.

• If the unit is to be connected to a circulation unit installed in a higher place than it, beware of the

backflow of the circulating fluid. If the fluid flows back, it may overflow the water bath of the unit.

Add a valve to the circulating path or take other proper measures to prevent a backflow.

7

Connecting the power.

Confirm that the earth leakage breaker is turned off, then connect the power plug (BB300/400 type)

and the circle terminal (BB600 type) to switchboard or receptacle.

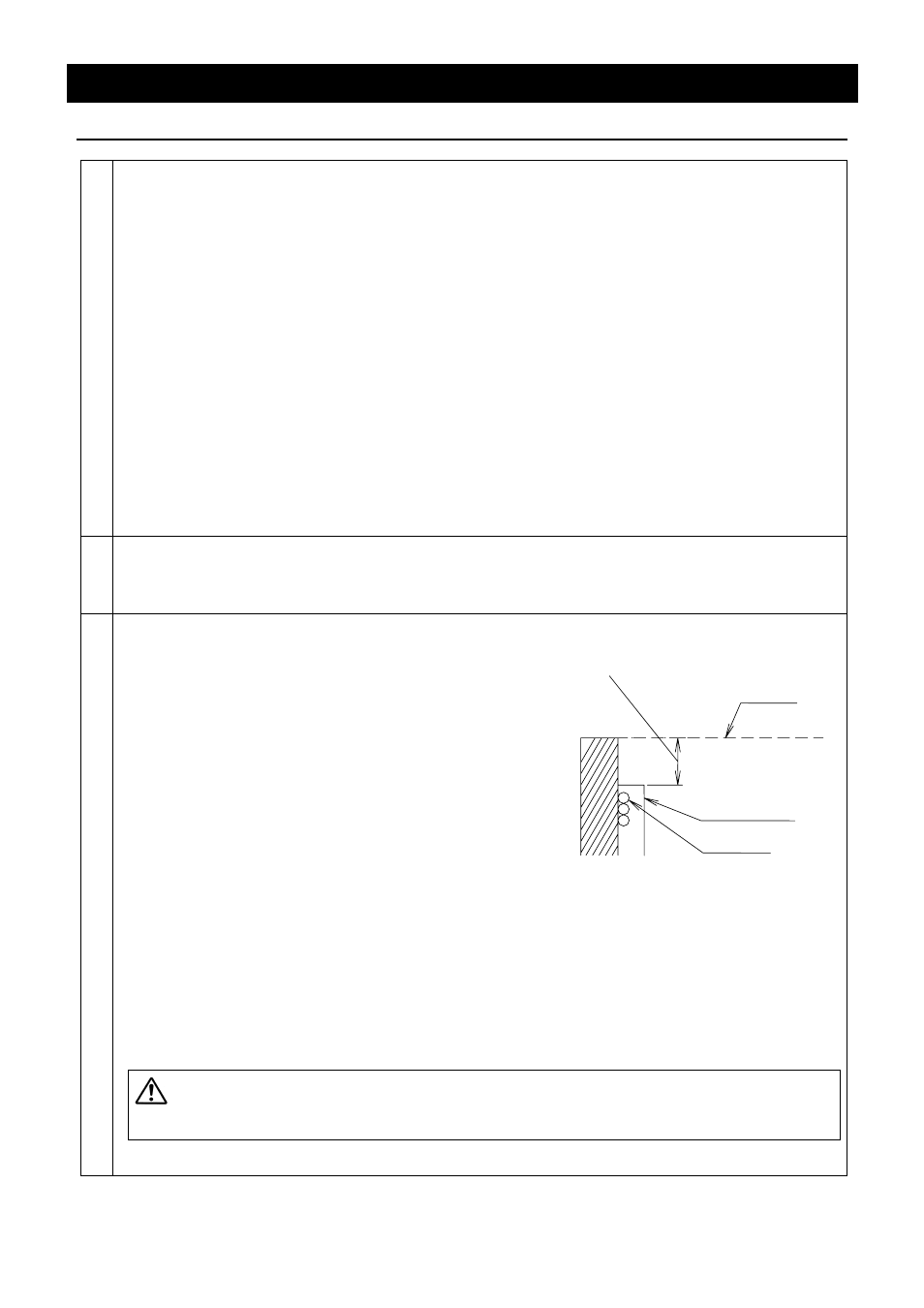

Pour circulating fluid into the bath.

• Check overflow. Connect the attached

hose for overflow to the overflow port, and

place the hose point in a container etc.

Prepare a container separately.

• Confirm that the drain cock is closed. Pour

the circulating fluid over the level of the

cooling coil. Set the circulating fluid level

as follows.

• Bath capacity – BB300 type: 6, BB400

type: 13, BB600 type: 26

Be careful that it may leak outside if the

quantity is beyond the capacity.

8

• Go on to the next operation at this state.

Turn on the earth leakage breaker and RUN/STOP key, and circulate the fluid.

• In external sealing system connection, open the discharge valve for circulation and circulate to

the device of external sealed system to be cooled. After it is stabilized, supply circulating fluid

to the proper level shown as below.

• After the resupply of the circulating fluid, turn "off" the leakage breaker.

Caution) Slowly pour the circulating oil.

Exercise care not to allow the circulating fluid to get on the unit. If it gets on any electric

part, leakage or electric shock may result. If it splashes on the operation panel, wipe it

out.

35mm (BB300/400 type)

30mm (BB600 type)

Bath top

Bath

Proper water level

Cooling coil fixing plate

Cooling coil