Burnham SCG 1100-H4 User Manual

Page 47

47

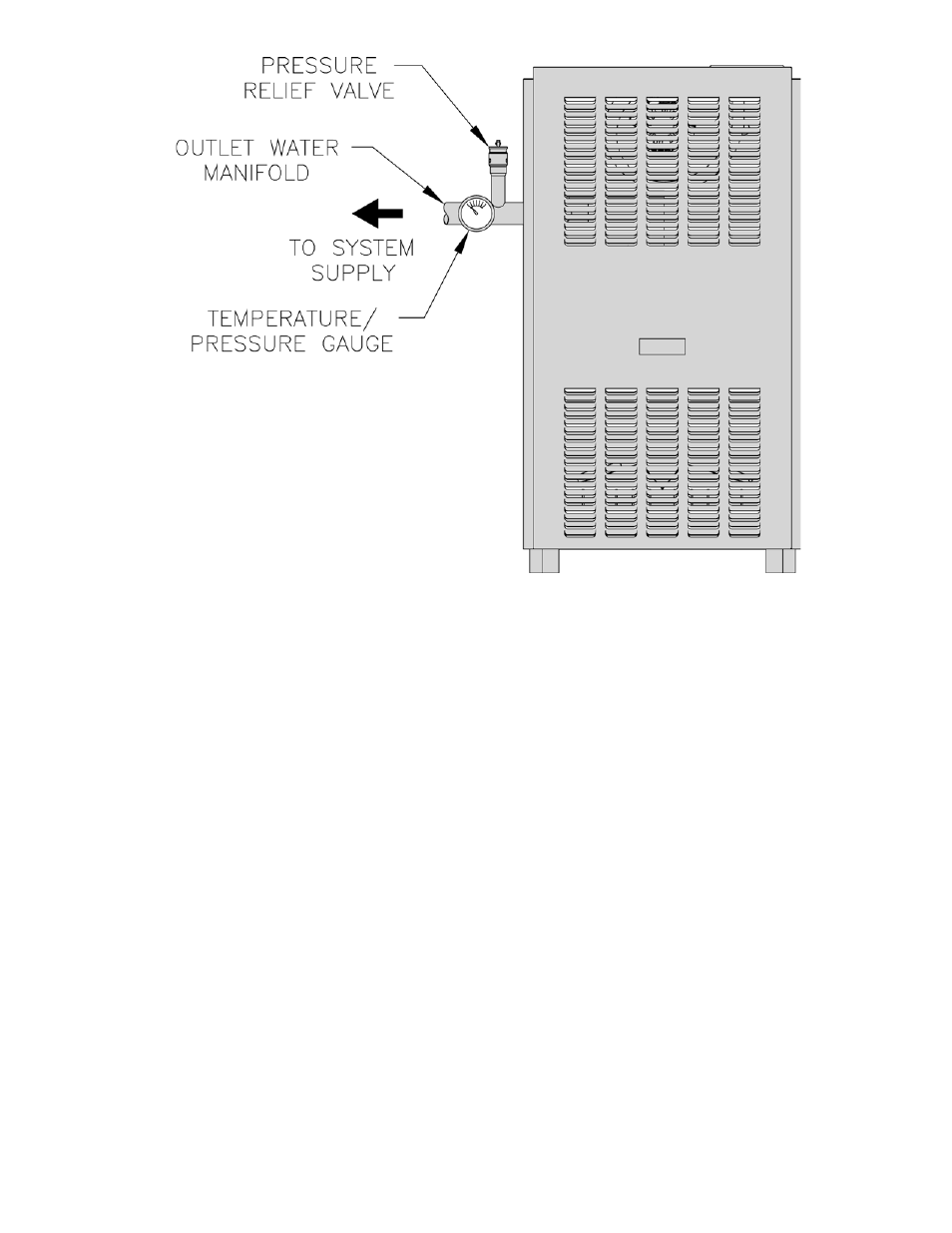

Figure 4: Supply Water Manifold Piping

Install pipe tee between circulator and boiler return

along with second tee in supply piping as shown in

Figure 25 or 26. Bypass should be same size as the

supply and return lines with valves located in bypass

and supply outlet as illustrated in Figure 25 or 26 in

order to regulate water flow to maintain higher boiler

water temperatures.

After the boiler is operational (reference Section VIII.

System Start-Up) set by-pass and boiler supply valves

to half throttle position to start. Operate boiler until

system water temperature reaches normal operating

range.

Adjust valves to provide 180° to 200°F supply water

temperature. Opening the boiler supply valve will raise

system temperature, while opening the by-pass valve

will lower system supply temperature.

J.

A hot water boiler installed above radiation level

must be provided with a low water cutoff device as part

of installation.

K

. If a low water cutoff is required, it must be mounted

in the system piping above the boiler. The minimum

safe water level of a hot water boiler is just above the

highest water containing cavity of the boiler; that is, a

hot water boiler must be full of water to operate safely.

L.

Oil, grease, and other foreign materials which

accumulate in new hot water boilers and a new

or reworked system should be boiled out, and

then thoroughly flushed. A local qualified water

treatment chemical specialist is a suggested source

for recommendations regarding appropriate chemical

compounds and concentrations which are compatible

with local environmental regulations.

M.

After the boiler and system have been cleaned and

flushed, and before refilling the entire system add

appropriate water treatment chemicals, if necessary, to

bring the pH between 7 and 11.

N.

If it is required to perform a long term pressure

test of the hydronic system, the boiler should first be

isolated to avoid a pressure loss due to the escape of air

trapped in the boiler.

To perform a long term pressure test including the

boiler, ALL trapped air must first be removed from the

boiler.

A loss of pressure during such a test, with no visible

water leakage, is an indication that the boiler contained

trapped air.