Warning, Iv. water piping and trim – Burnham SCG 1100-H4 User Manual

Page 45

45

A.

Design and install boiler and system piping to

prevent oxygen contamination of boiler water and

frequent water additions.

1. There are many possible causes of oxygen

contamination such as:

a. Addition of excessive make-up water as a result

of system leaks.

b. Absorption through open tanks and fittings.

c. Oxygen permeable materials in the distribution

system.

2. In order to insure long product life, oxygen sources

must be eliminated. This can be accomplished by

taking the following measures:

a. Repairing system leaks to eliminate the need for

addition of make-up water.

b. Eliminating open tanks from the system.

c. Eliminating and/or repairing fittings which allow

oxygen absorption.

d. Use of non-permeable materials in the

distribution system.

e. Isolating the boiler from the system water by

installing a heat exchanger.

f. Use properly designed and operating air

elimination devices in water piping.

B.

Low Water Cut Off (LWCO) on Hot Water Boilers

(Optional)

WARNING

DO NOT ATTEMPT to cut factory wires to

install an aftermarket low Water Cut Off

(LWCO). Only use connections specifically

identified for Low Water Cut Off.

In all cases, follow the low Water Cut Off

(lWCO) manufacturer’s instructions.

When

A low water cutoff is required to protect a hot water

boiler when any connected heat distributor (radiation)

is installed below the top of the hot water boiler (i.e.

baseboard on the same floor level as the boiler). In

addition, some jurisdictions require the use of a LWCO

with a hot water boiler.

IV. Water Piping and Trim

Where

The universal location for a LWCO on both gas and oil

hot water boilers is above the boiler, in either the supply

or return piping. The minimum safe water level of a

water boiler is at the uppermost top of the boiler; that is,

it must be full of water to operate safely.

What Kind

The SCG boiler is designed to accept the wiring of the

Safgard Model 1100-H4 (P/N 100592-01) LWCO. This

is a probe type LWCO. The factory wiring is designed

to allow simple “Plug-in” installation of the wiring.

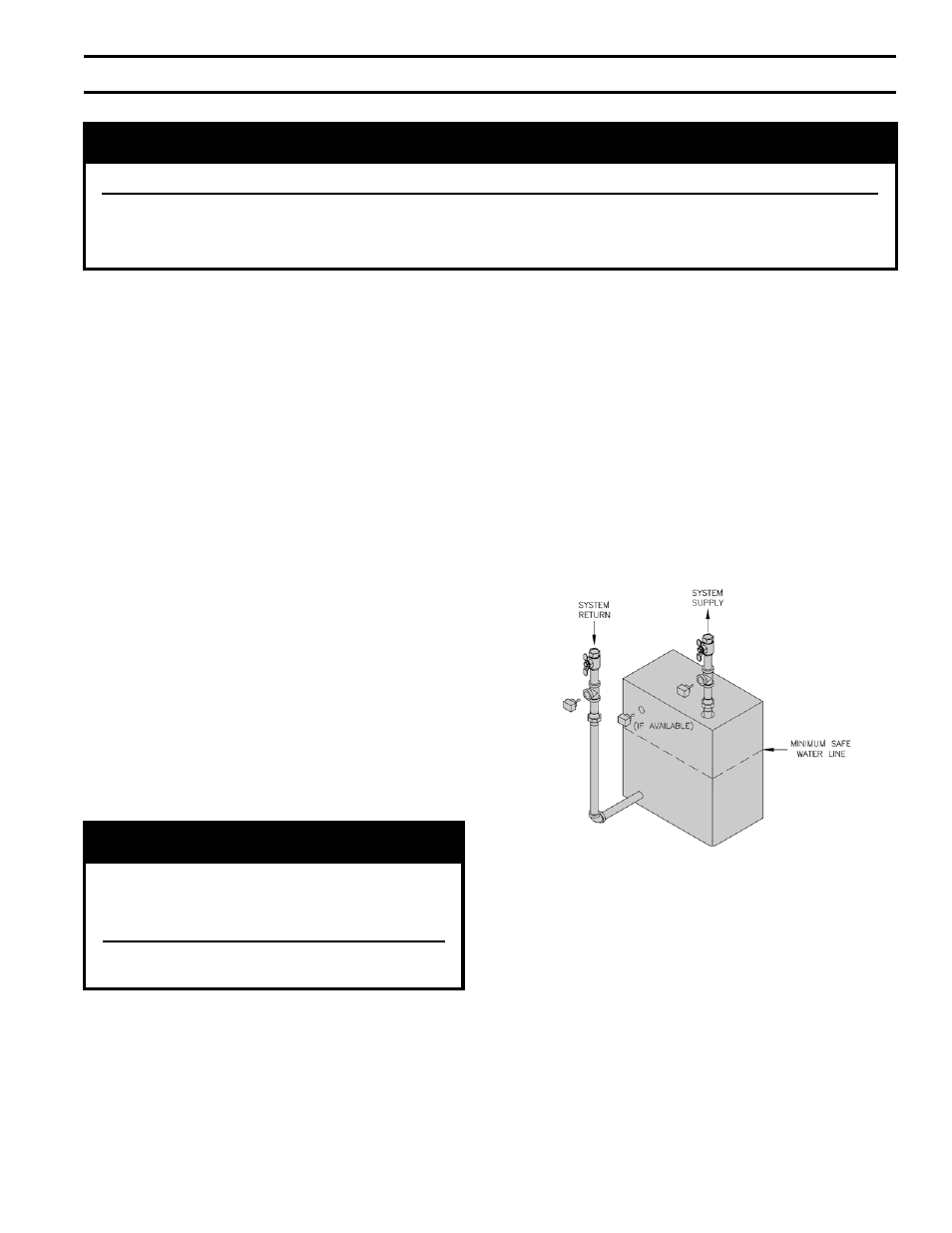

How to Pipe

A “tee” is commonly used to connect the probe LWCO

to the supply or return piping, as shown below.

lWCO location

Select the appropriate size tee using the LWCO

manufacturer’s instructions. Often, the branch

connection must have a minimum diameter to prevent

bridging between the probe and the tee. Also, the run

of the tee must have a minimum diameter to prevent

the end of the probe from touching or being located too

close to the inside wall of the run of the tee.

Ideally, manual shutoff valves should be located

above the LWCO and the boiler to allow for servicing.

This will allow probe removal for inspection without

draining the heating system. Many probe LWCO

manufacturers recommend an annual inspection of the

probe.

WARNING

Failure to properly pipe boiler may result in improper operation and damage to boiler or structure.

Oxygen contamination of boiler water will cause corrosion of iron and steel boiler components, and

can lead to boiler failure. Burnham’s Standard Warranty does not cover problems caused by oxygen

contamination of boiler water or scale (lime) build-up caused by frequent addition of water.