Burnham SCG 1100-H4 User Manual

Page 31

1

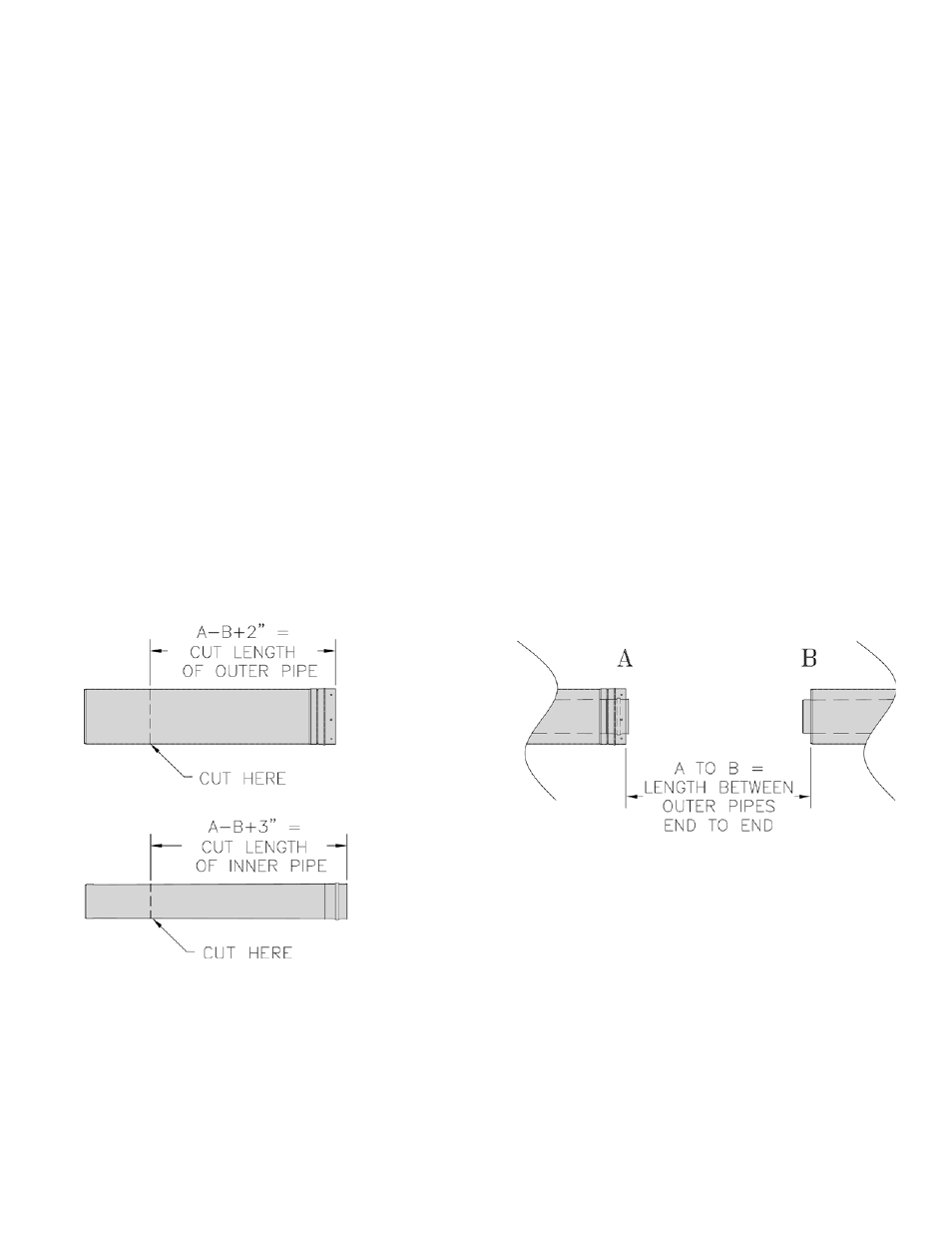

8. Straight Sections Cut To Length:

If a custom length of SC is necessary, a standard vent

section can be cut.

a. Measure the distance of the length needed, taking the

measurement from the end of one of the outer jackets

to the beginning of the other outer jacket on the

section to connect to, (A to B on diagram).

b. Select a section that is longer than the required

length.

c. It will be necessary to disassemble the vent prior to

cutting.

Stand the section on end with the holes up. Find the

end of snap ring and pry it out of its groove, being

careful not to damage the ends of the vent pipes.

Pull up on end of the snap ring and pull it out from

the end of the pipe. It may want to spiral out as it is

removed. After the snap ring is removed, the inner

vent pipe can be separated from the outer jacket.

d. Add

2” to the distance measured previously for the

cut length of the outer jacket. Mark a cut line on the

outer jacket on the male end (the end without holes in

it).

An effective way of marking is to run a length of tape

around the section, assuring a square cut.

e. Add

3” to the distance measured previously for the

cut length of the inner vent pipe. Mark a cut line on

the inner vent on the male end (the end without the

red seal).

The inner pipe is always cut 1” longer than the

outer pipe.

f. WEAR GLOVES, as cut ends are very sharp. Cut

the pipes with an abrasive cutoff saw, plasma cutter,

or compound snips. If using snips, start the cut at

the male end and follow a spiral path around the pipe

until the cutoff mark is reached. File off any burrs

or rough edges that develop in the cutting process

and clean off any dust or grit. If the cutting process

distorts the roundness of the pipes, carefully use your

thumbs to re-round the ends.

g. Reassemble the inner vent into the outer jacket and

reinstall the snap ring into the groove. Push the

inner vent into the outer jacket until the triangle on

the inner vent is seated firmly against the bead on

outer jacket. Start one end of the snap ring into the

groove of the outer pipe. Slowly turn and feet the

snap ring into the groove in a spiral motion, and

continue around the pipe until the snap ring is fully

inserted. Ensure that the triangle on the inner vent is

all the way down against the bead of the outer jacket

by pushing in firmly. Also ensure that the snap ring

is completely in the groove all the way around outer

jacket.