Danger – MacDon R85 Rotary Disc 13 Foot User Manual

Page 55

OPERATION

169454

53

Revision C

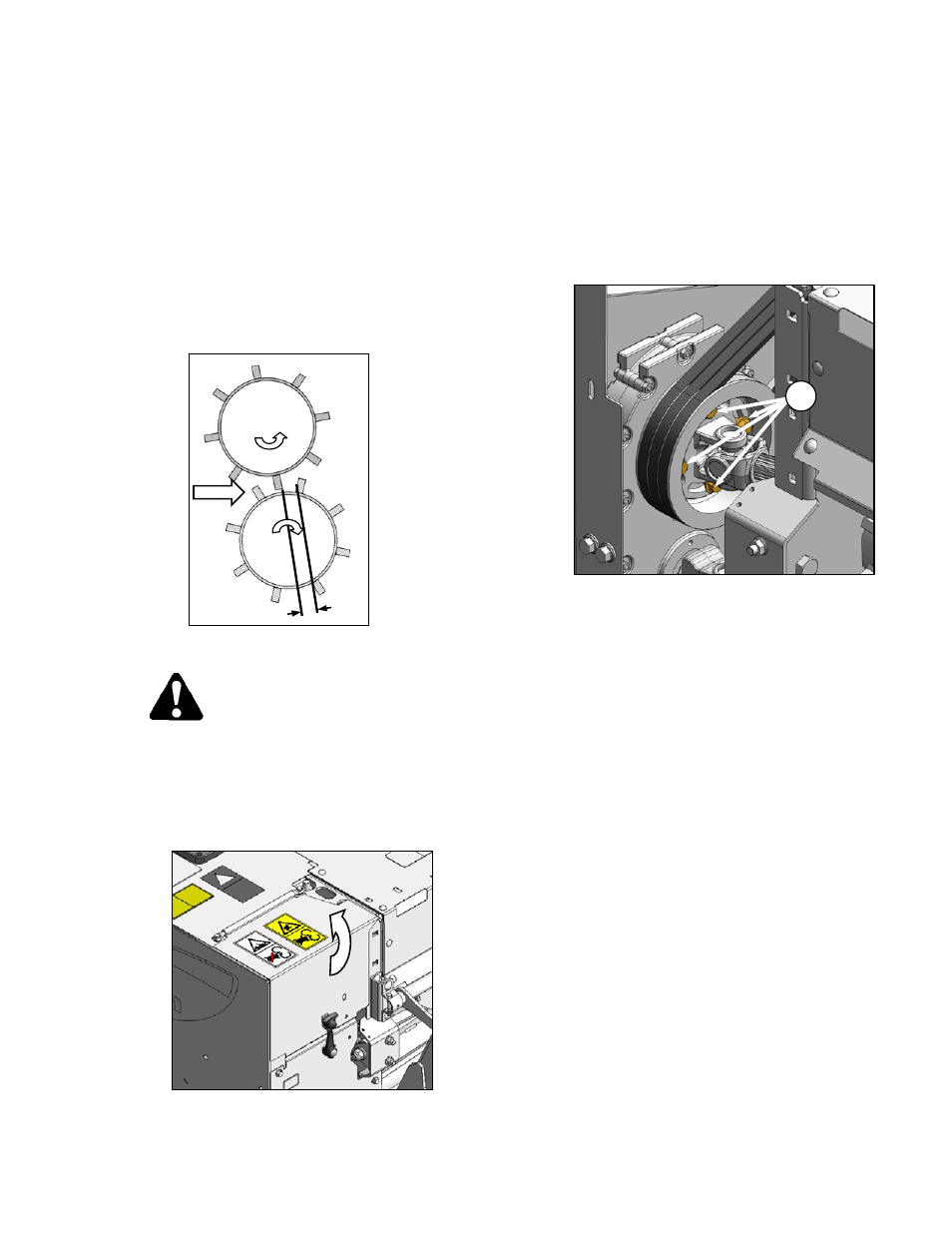

6.12.4 Roll Timing

For proper conditioning, the rolls must be

properly timed with each steel bar on one roll

centered between two bars of the other roll as

shown. The factory setting should be suitable

for most crop conditions.

IMPORTANT

Roll timing is critical when the roll gap is

decreased because:

Conditioning is affected, and

The bars may contact each other.

To check roll timing ‘X’, proceed as follows:

DANGER

Stop engine, and remove key from ignition

before leaving Operator's seat for any

reason. A child or even a pet could engage

an idling machine.

a. Lower header fully, stop engine, and remove key

from ignition.

b. Open the driveshield. See Section 6.2.2

Driveshield.

c. Examine roll timing (distance ‘X’) at each end of

the rolls with the header fully lowered. Each

steel bar on one roll should be centered

between two bars of the other roll so that

distance ‘X’ is approximately equal on both

sides of the bar.

6.12.4.1 Roll Timing Adjustment

Adjust roll timing, if necessary, as follows:

a. Loosen four bolts (A) in slots of yoke plate on

upper roll universal shaft.

b. Manually rotate upper roll it stops. Make a mark

on yoke flange to align with the center of one of

the bolt (A) heads.

c. Manually rotate upper roll in opposite direction

until it stops. Make a second mark on yoke

flange to align with the bolt.

d. Determine the center between the two marks,

and mark a third line on the yoke flange.

e. Rotate the upper roll until the bolt lines up with

the third line.

f. Tighten bolts (A) to secure the position. Torque

to 70 lbf·ft (95 N·m).

A

CROP

X