Precision Turbo and Engine BigStuff3 GEN3 PRO SEFI (LS1) System Hardware & BigComm Software User Manual

Page 43

BigStuff3 Pro SEFI System (LS1)

Version 1.0

42

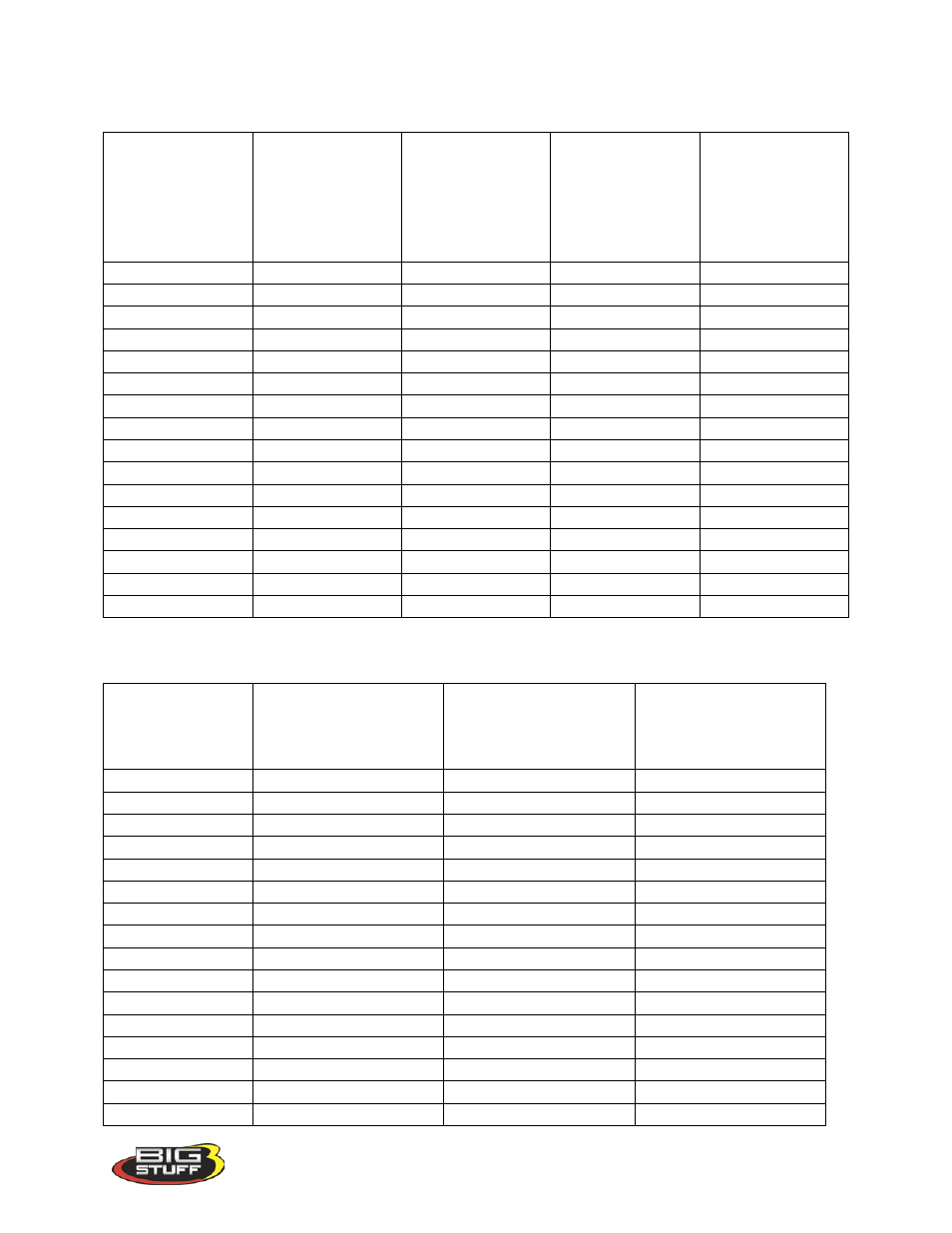

The following table offers default Load schedules for 1, 2, 3, & 5 BAR MAP sensor

applications.

MAP (KPa)

(Y Axis)

Cell Number

Load Schedule

for 1 BAR MAP

Sensor

(Normally

Aspirated

Engine)

Load Schedule

for 2 BAR MAP

Sensor (Up to

15 PSI of Boost)

Load Schedule

for 3 BAR MAP

Sensor (Up to

30 PSI of Boost)

Load Schedule

for 5 BAR MAP

Sensor (Over 30

PSI of Boost)

16

106

205

300

500

15

100

195

275

450

14

95

180

250

400

13

90

165

225

350

12

85

150

200

300

11

80

135

175

25

10

75

125

150

200

9

70

115

125

175

8

65

105

110

150

7

60

95

100

125

6

55

85

90

100

5

50

75

80

90

4

45

65

70

80

3

40

55

60

70

2

35

45

50

60

1

30

35

40

50

The following table offers default RPM Schedules for several engine configurations.

RPM (Y Axis)

Cell Number

RPM Schedule for a

Stock (Torque)

Engine

RPM Schedule for a

Mild Street Engine

(6,500 Max RPM)

RPM Schedule for a

High RPM Racing

Engine (9,500 Max

RPM)

16

5,200

6,000

9,500

15

4,800

5,500

9,000

14

4,400

5,000

8,500

13

4,000

4,500

8,000

12

3,600

4,000

7,500

11

3,200

3,600

7,000

10

2,800

3,200

6,500

9

2,400

2,800

6,000

8

2,000

2,400

5,000

7

1,800

2,100

4,000

6

1,600

1,800

3,500

5

1,400

1,500

3,000

4

1,200

1,200

2,500

3

1,000

1,000

2,000

2

800

800

1,500

1

600

600

1,000