Transducer interface, Transducer interface 24 – MTS WIFT Mini Transducer Interface User Manual

Page 24

SWIFT

®

Mini TI

24

Transducer Interface

Hardware Overview

Transducer Interface

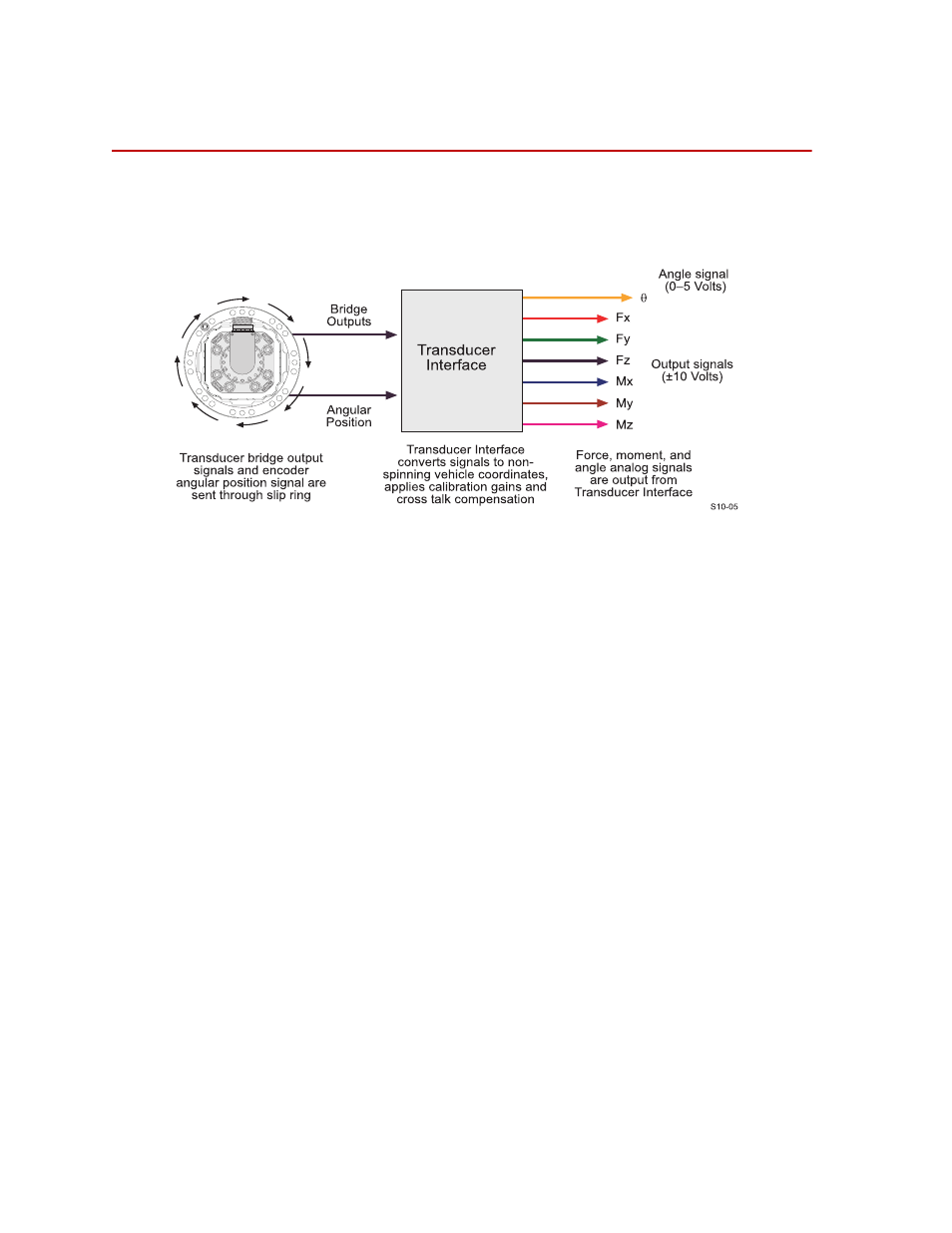

The TI performs cross talk compensation, transforms the loads from a rotating to

a non-rotating coordinate system, and produces an analog output signal suitable

for most data recorders.

Cross talk

compensation

Cross talk occurs when a force is applied to one axis, but a non-real force is

measured on another axis. The SWIFT sensor design has very low inherent cross

talk. The TI compensates for cross talk by subtracting cross talk values measured

during calibration.

Signal conditioning

The TI is specifically designed to be used for both spinning and non-spinning

applications. The TI performs signal conditioning and communications

functions. The output from the TI is a high-level signal suitable for input into a

multichannel data recorder or an MTS Automated Site Controller (ASC).

The TI transforms eight inputs (amplified bridge signals) into three forces and

three moments by the following process:

•

Applying a zero offset and scaling the signals

•

Using a geometric matrix to transform the signals into three forces and three

moments in the transducer reference frame

•

Using a cross-coupling matrix calculation to scale and sum the individual

signals into each output

•

Using an offset matrix to shift the coordinate system along the y-axis

•

In spinning applications, using a rotational transformation to put the forces

and moments into a stationary reference frame

or

Angular Velocity

signal (+/- 10 V)