Operation – Leica Biosystems SP2600 User Manual

Page 23

23

Leica SP2600 Ultramilling attachment

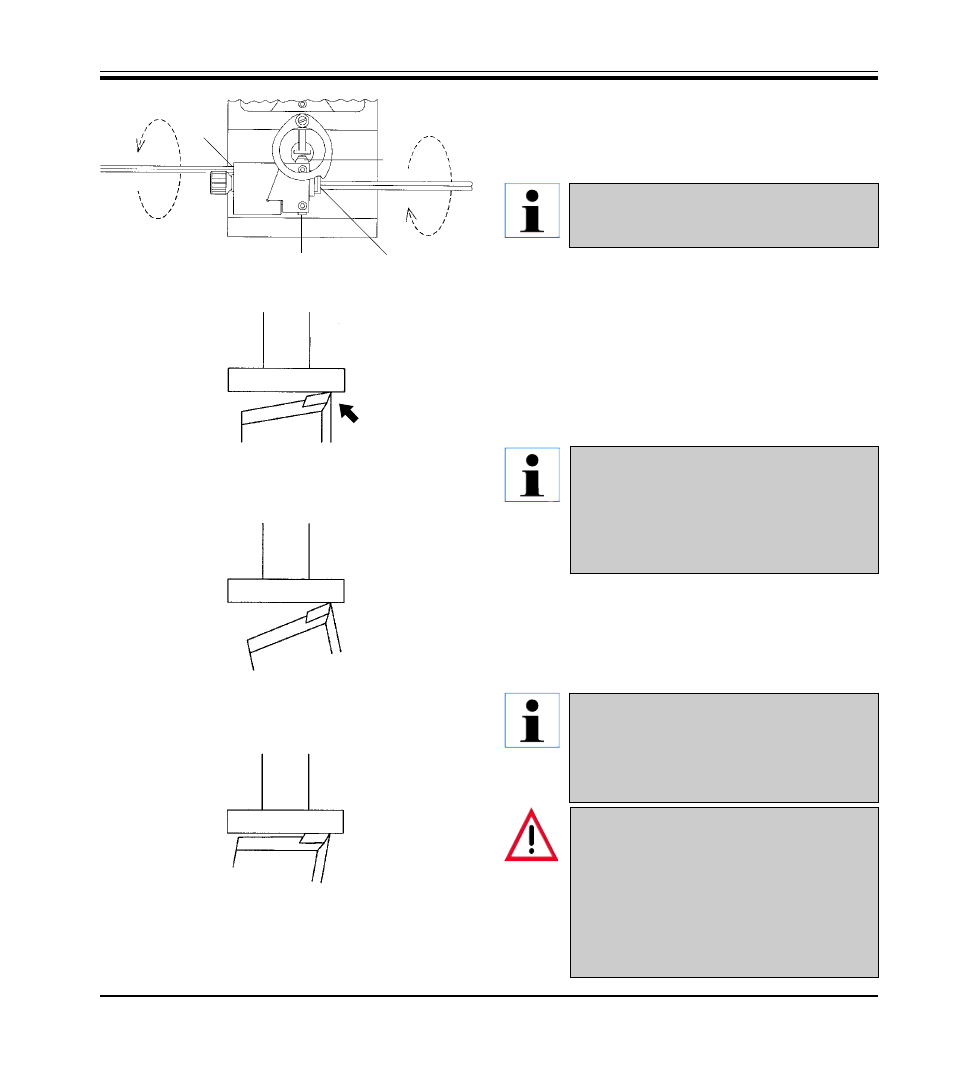

6. Insert the size-5 Allen key into regulating

screw (4) insert size-2.5 Allen key into regu-

lating screw (11) (Fig. 5.7).

The arrows in Fig. 5.7 indicate clock-

wise sense of rotation.

7. Tighten/loosen screws (11) and (4) alternately

to adjust miller (3) along the z-axis. The miller

edge is adjusted correctly when the outer

edge of the miller is at right angles to the front

surface of the contact plate (see Fig. 5.8a).

The miller MUST NOT be positioned as shown

in Fig. 5.8b and 5.8c!

Tightening either regulating screw (4,

11) (= clockwise rotation in the sense

of the arrow) brings the corresponding

side of the miller closer to the contact

plate.

8. If one of the two screws (4, 11) has been tight-

ened as far as it will go, slightly release the

opposite screw. This slackens the screw that

had been completely tightened .

Do not tighten screws (4, 11) too much.

If screws (4, 11) are too tight, screw (7,

Fig. 5.2) (for adjustment along the y-

axis) can no longer be moved.

Caution:

Be very careful when bringing the

contact plate close to the milling

edge.

Always use the magnifier.

Make sure the milling edge does not

hit the contact plate!

Fig. 5.8 b - WRONG

Fig. 5.8 a - CORRECT

5. Operation

Fig. 5.7

4

11

3

7

Fig. 5.8 c - WRONG

90°