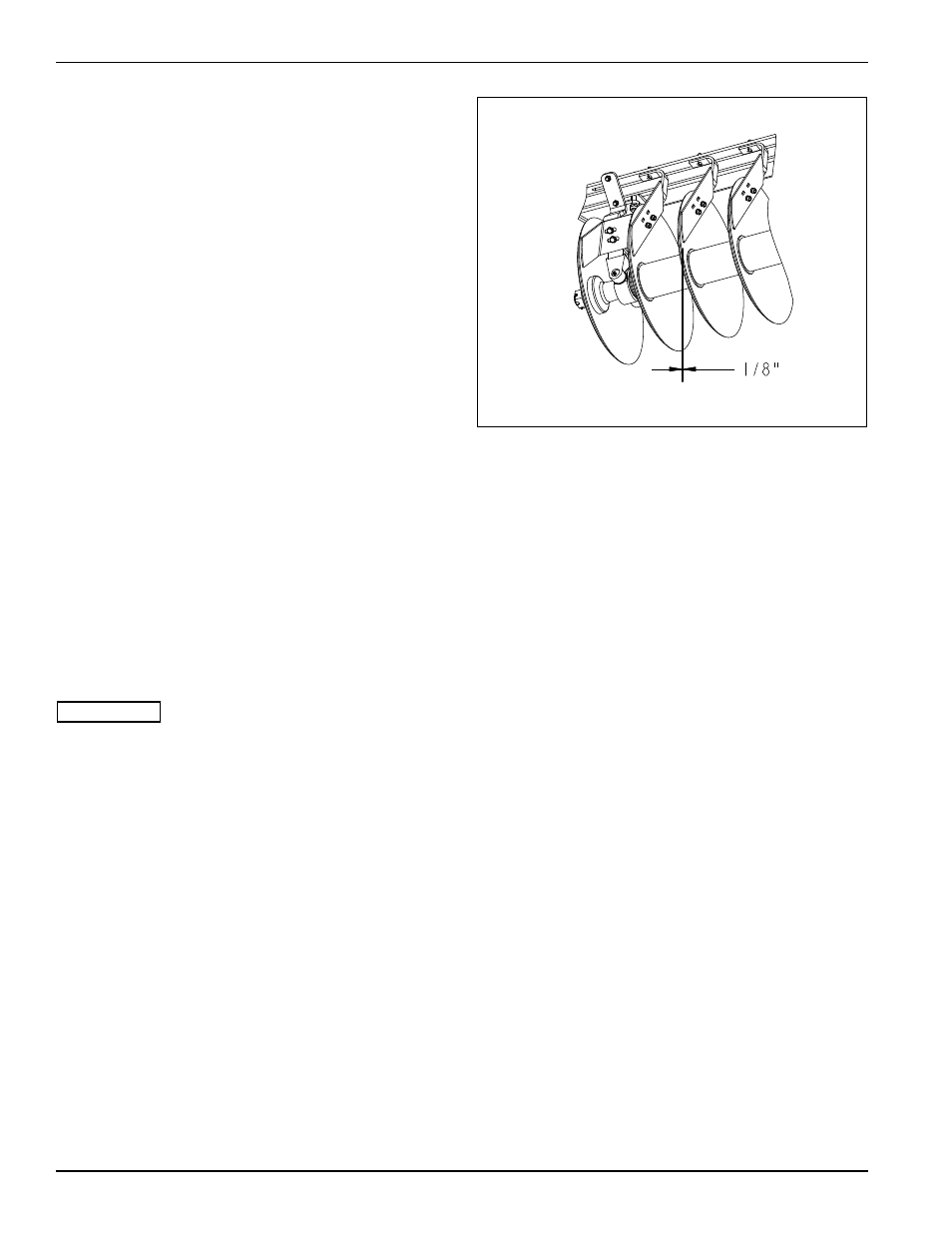

Tractor preparation, Weatherproofer preparation, Figure 4-1: disc scraper clearance to disc blade – Landoll 2410F Weatherproofer I User Manual

Page 56: Attaching to the tractor

4-2

F-735-0114 Edition

OPERATION AND MAINTENANCE

Tractor Preparation

The Landoll 2410F Weatherproofer I is designed to be

pulled by tractor equipped with a double lip or clevis type

hitch. If your tractor is not equipped as such, you need to

purchase the hitch from your local tractor dealer. If your

Weatherproofer is equipped with the clevis option, this

should be removed. The clevis option is only for transport

use. Before attaching the Weatherproofer, prepare the

tractor as follows:

1.

Inflate the rear tractor tires equally and add ballast

according to the tractor operator’s manual.

2.

Lock the tractor drawbar in the center position.

Weatherproofer Preparation

1.

Prior to operating the 2410F Weatherproofer I,

inspect it thoroughly for good operating condition.

2.

Replace worn or missing parts.

3.

When the machine is new, check the bolt tightness

after a few hours of operation. Tighten any loose nuts

or bolts. Check the gauge wheel lug bolts daily.

4.

Check the lift wheel tire inflation. Inflate all tires

equally to avoid side draft. Follow the tire

manufacturer’s recommended pressures listed on

the sidewall of the tires.

5.

Check disc scrapers for proper adjustment to the disc

blade (See Figure 4-1.)

a.

Loosen U-bolts. Slide scraper assembly to adjust

clearance to 1/8" to 1/4".

IMPORTANT

Under certain conditions, it may be beneficial to set

scrapers as much as 1" away from the discs.

6.

Lubricate the machine as shown in “Lubrication

Maintenance” on page 4-10 (See Figure 4-11.)

Figure 4-1: Disc Scraper Clearance to Disc Blade

Attaching to the Tractor

1.

Align the tractor drawbar with the machine. Attach

the unit with proper size hitch pin. Attach safety chain

and plug in light plug.

2.

Clean all hydraulic couplings and attach to the

tractor. When properly attached, the hydraulic control

lever should cause the Weatherproofer to:

a.

Lower to the ground when the control arm is

moved forward or downward, and

b.

Raise when the control arm is moved backward

or upward.

3.

Fully extend the hydraulic gauge wheel cylinders,

and place the cylinder lockouts in the transport lock

position over the cylinder rods. Secure the lockouts

with the lockout pins.

4.

Always place the swivel jack on the interior mount

before setting the machine in motion. Remove rear

jack stand if an attachment is used.