Landoll 7431 VT Plus User Manual

Page 62

3-38

F-561-0113 Edition

ASSEMBLY INSTRUCTIONS

Finishing Hydraulic Conditioner

Reel Installation (Option)

NOTES

Refer to Figure 3-25 for hydraulic diagram for the

7431-20 model.

Refer to Figure 3-26 for hydraulic diagram for the

7431-23 model.

Refer to Figure 3-27 for hydraulic diagram for the

7431-26 model.

Refer to Figure 3-28 for hydraulic diagram for the

7431-29 model.

Refer to Figure 3-29 for hydraulic diagram for the

7431-33 model.

Refer to Figures 2-1 - 2-12 for hose clamp locations.

1.

Attach reel arm assemblies to rear frame in top hole

using 1-8 x 6-1/2 hex head cap screw, pivot bushing,

flange bearings, and hex lock nut (See Figure 3-30.)

2.

Attach 17” spring assembly and 2-1/2 hydraulic

cylinder to lower hole on rear frame using cylinder

trunnion, cylinder trunnion stop, 1/2-13 x 1-1/2 hex

head cap screw, and split lock washer.

NOTE

On 7431-33 models, center reel arm has regular spring

setup.

3.

Install the manifold to the manifold bracket on the

frame using 1/2-13 x 3-1/2 hex head cap screws and

hex lock nuts.

4.

Install fittings into manifold according to Figures 3-25

thru 3-29.

5.

Install hoses per Figures 3-25 thru 3-29.

6.

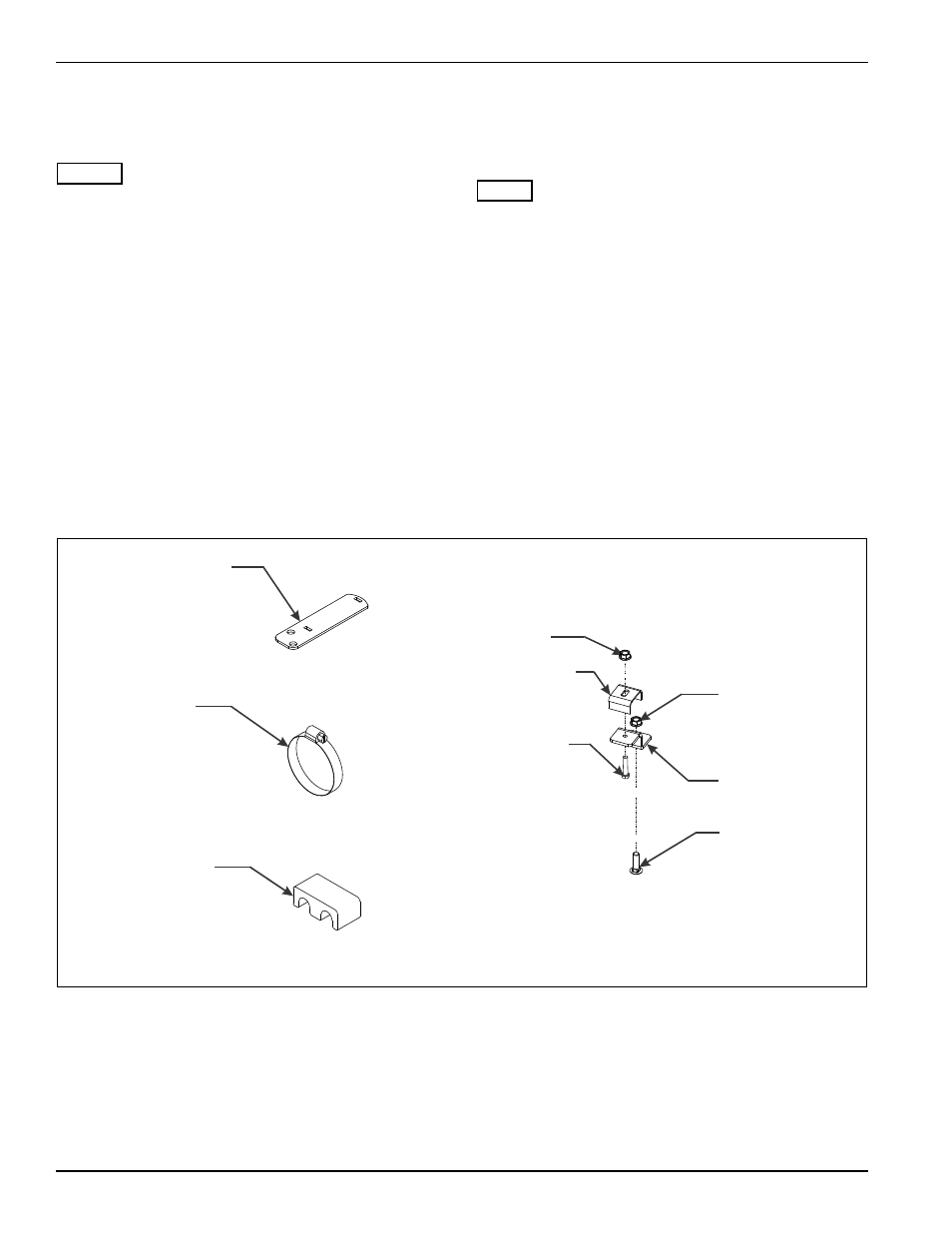

Install hose clamps onto frame (See Figures 3-31

and 3-32.)

7.

Install steel plugs in any remaining open manifold or

valve ports.

8.

Attach conditioner reel/gang bar assembly to reel

arm assemblies using gang bar mount plates, 3/4-10

x 6 hex head cap screws, and double hex lock nuts.

Figure 3-31: Finishing Hydraulic Conditioner Reel Hose Clamp Installation (Option)

BULKHEAD PLATE

2-1/2 - 8-1/2

OR

4-1/2 - 6-1/2

HOSE CLAMP

2 HOSE CLAMP

HOSE CLAMP

3/8-16 FLANGE

LOCK NUT

HOSE CLAMP

3/8-16 X 1-1/2

HEX HEAD

CAP SCREW

1/2-13 FLANGE

LOCK NUT

HOSE CLAMP

BRACKET

1/2-13 X 1-1/2

RD HEAD SQ

NECK SCREW

hyd cond reel hose clamps