Hydraulic installation, Caution – Landoll 7450 VT Plus User Manual

Page 39

ASSEMBLY INSTRUCTIONS

3-21

Hydraulic Installation

NOTE

See Figures 3-11 through 3-16 for hydraulic cylinder

fittings (factory installed and those installed during

setup).

Refer to Figures 3-11- 3-12 for lift and fold hydraulic

diagrams for 7450-39' model.

Refer to Figures 3-13- 3-14 for lift and fold hydraulic

diagrams for 7450-44' model.

Refer to Figures 3-15 - 3-16 for lift and fold hydraulic

diagrams for 7450-49' model.

Refer to Figure 3-17 for transport lock hydraulic

diagram, front and rear manifold drawings, and fold

cylinder detail for all models.

1.

Attach the base end of the 4 x 30 (7450-39’/

7450-44’) or 4-1/2 x 30 (7450-49’) fold cylinder to the

fold cylinders mounts on the center frame with the

pins and roll pins as designated in Figure 3-18.

Position the cylinders so the hydraulic ports point to

rear on front and to front on the rear and toward the

center of machine.

2.

Using a 1-1/4 x 6-1/8 fold pin, flat washers, and 5/16

x 2-1/2 roll pins, attach the rod end of the 4” x 30”

cylinders to the slotted mounts on the inner wing

frames (See Figure 3-18.)

3.

Using 1-1/4 x 6-1/8 fold pin (7450-39’) or pins

provided with cylinder (7450-44’/7450-49’), attach

base of outer wing fold cylinder to mount on inner

wing.

4.

Using a 1-1/4 x 9-9/16 fold pin, flat washers, wing

fold rollers, wing fold spacers, and 5/16 x 2-1/2 roll

pins, attach the rod end of the 4” x 30” cylinders to

the fold links on the double hinge (See Figure 3-18.)

NOTE

Rod ends of fold cylinders need to be left unassembled

until fold hydraulic system is fully charged with oil to

prevent machine damage.

5.

Install 90 degree regular adapter fittings in both ends

of all lift cylinders and transport lock cylinders (4-1/2

x 16, 4 x 16, 3-3/4 x 16, 3-1/2 x 8, and 3-1/4 x 8).

CAUTION

6.

Install the 16 port front manifold to the manifold

bracket on the front of the center frame using 1/2-13

x 3-1/2 hex head cap screws and hex lock nuts.

7.

Attach the 8 port manifold to the rear manifold

bracket on the implement using 1/2-13 x 3-1/2 hex

head cap screws and hex lock nuts.Install lift system

hoses per Figures 3-11 and 3-15. Wrap lift system

hoses with blue hose wrap.

8.

Attach hose clamp brackets to the scraper bar (See

Figure 3-19.) Secure hoses to the brackets with

hose clamps, 3/8-16 x 1-3/4 hex head cap screws,

and hex lock nuts.

9.

Install fold system hoses per Figures 3-12 and 3-16.

Wrap fold system hoses with yellow hose wrap.

10. Install 1/32” restrictors, (2) 290” hoses, and couplers

in the hydraulic leveler. Wrap hydraulic leveler hoses

with black hose wrap.

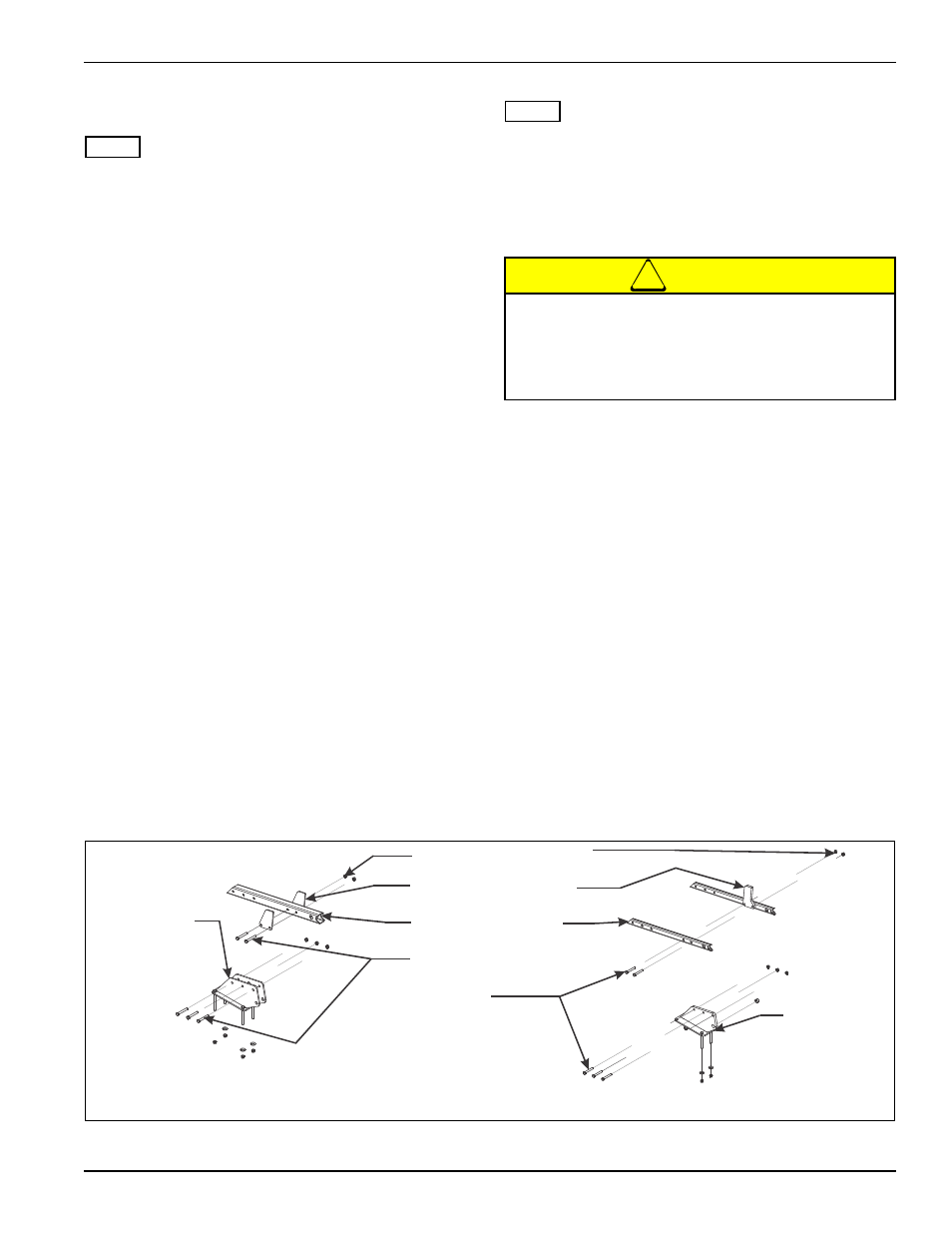

11. Attach outer wing stops and wing stabilizer to fold

stabilizer mount using 3/4-10 x 5 hex head cap

screws and hex lock nuts (See Figure 3-20.)

Figure 3-20: Wing Stabilizer Bracket Mounting Installation

1/16” Restrictors are installed in the rod end of

wing fold cylinders to prevent uncontrolled

dropping of wings. Removal of these restrictors,

or improper installation can result in serious

damage to the implement.

7450-39 AND -44 MODELS

3/4-10 HEX LOCK NUT

OUTER WING STOP

3/4-10 X 5 HEX

HEAD CAP

SCREW

WING STABILIZER

7450-49 MODEL

FOLD

STABILIZER

MOUNT

INSTALLED

AT LANDOLL

FOLD

STABILIZER

MOUNT

INSTALLED

AT LANDOLL