Landoll PFT Floating Ring Pulverizer User Manual

Page 15

298rev401

5K089

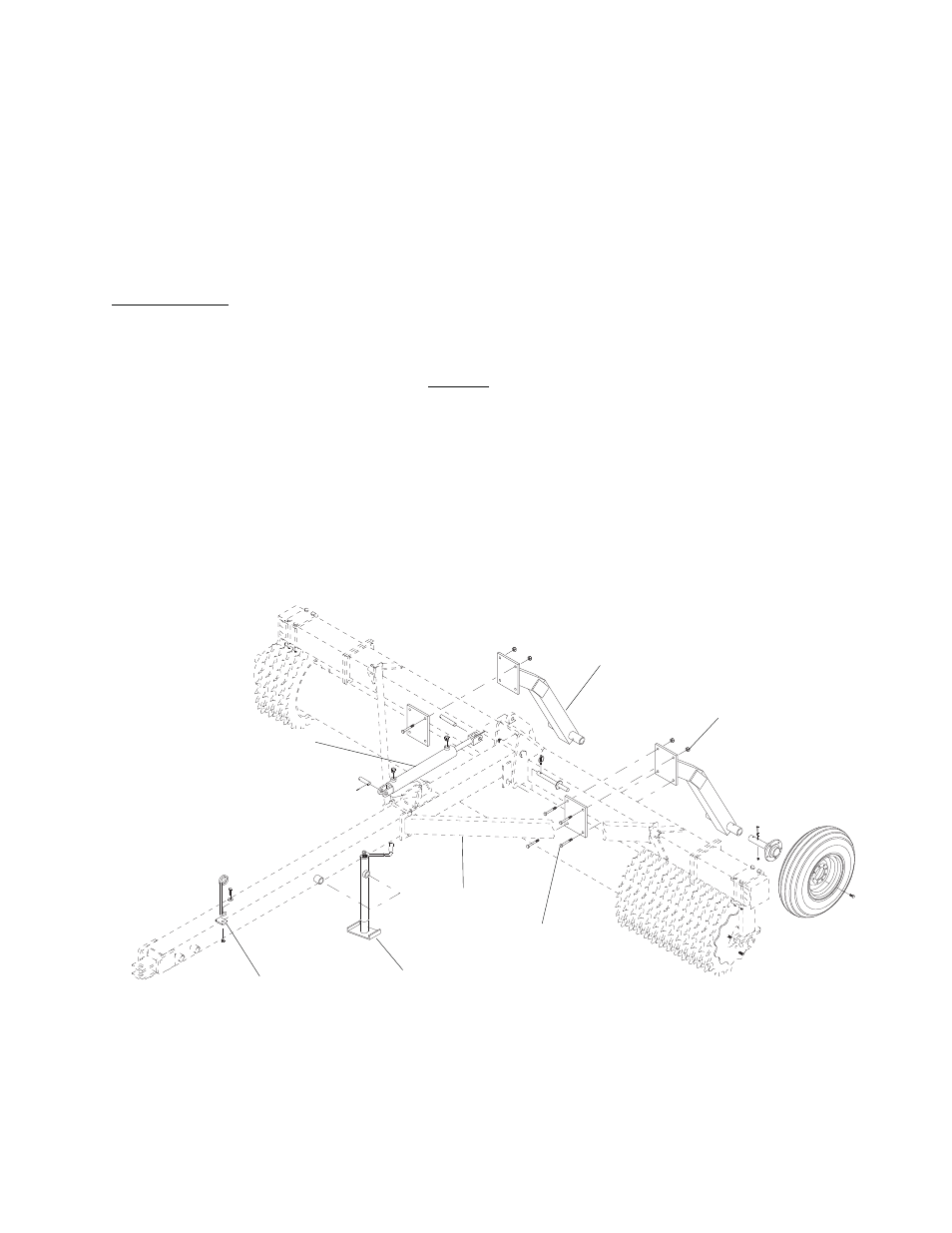

FIGURE 12

WHEEL ARM

BOLT,

5/8 X 9 1/2

LOCK NUT,

5/8

JACK

HOSE

SUPPORT

4K992

HYDRAULIC

CYLINDER

BRACE

Page 13

3. Next attach the two braces to the frame. Extend a 1" diameter by 5 1/2" long bolt through one of

the washers, then through the brace, then add another washer before extending the bolt through

the brace lugs on the frame, finally add one more washer and a 1" lock nut. Repeat this procedure

for both braces and tighten the lock nuts so that they permit rotation.

4. Rotate the braces so they are in line and against the drawbar. Extend 5/8" diameter by 8 1/2"

long bolts through the holes in the braces above and below the drawbar and secure the bolts

with 5/8" diameter lock nuts. These nuts should be tightened securely (150 ft-lb).

WHEEL ARMS

5. Attach the wheel arms to the center frame. The wheel arms should be equally spaced from the

center of the machine. It is recommended that the wheel arms be a minimum of 7 feet apart or

half the pulverizer width which ever is greatest. Fasten the wheel arms to the center frame as

shown with plates and four 5/8 x 9 1/2 bolts and 5/8 lock nuts per wheel. Tighten the lock nuts

to 150 ft.-lb. Attach rims to the hubs with the wheel bolts provided, and insert the spindle and

wheel assembly into the wheel arms. Use the hole in the spindle which is closest to the tire.

Lock the spindle in place with the 1/2" x 3" long cap screw and secure with the lock nut tightened

to 75 Ft.-lb. Mount the hose support and jack where shown.