Wear pad field replacement/adjustment, Wear pad field replacement/adjustment -28 – Kinze 3600 Lift and Rotate Planter (70 CM) Rev. 5/14 User Manual

Page 132

M0249-01

Model 3600

6-28

12/12

TM

Lubrication and Maintenance

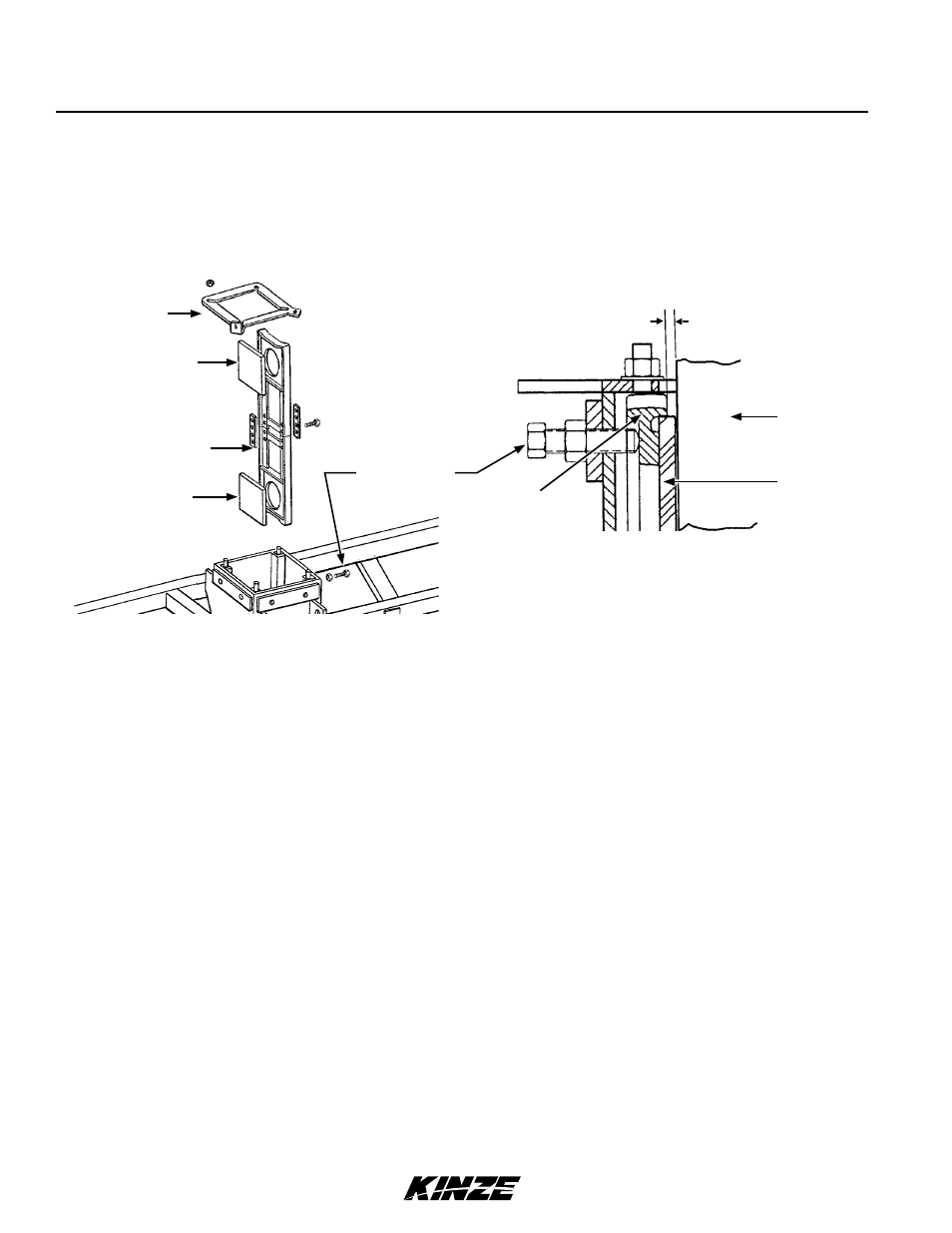

Planter center section is constructed around a steel tubular frame with four wear pad assemblies riding against a

stainless steel clad center post. Two wear pads are held by a pad holder and locked in place by ¾" adjusting bolts and

hex jam nuts. Inspect pads for wear and adjustment annually to ensure center section is stabilized and planter tracks

properly. Pads should make full light contact with center post when properly adjusted. Too much preload on pads will

cause hydraulic lift pressure to be higher than necessary or will not allow planter to raise when loaded.

1. Position planter on a level surface and place in raised field position.

NOTE: Replace wear pad when worn to less than .3 cm. See “Pad Replacement” steps on next page.

2. Visually check four upper wear pads. Each wear pad should lightly contact stainless steel clad center post.

3. Place planter in raised transport position, install all safety lockups and visually check four lower wear pads for light

contact.

4. Remove lockup and lower planter to field operation position. Loosen cap mounting nuts to allow wear pad

adjustment. Loosen hex jam nuts as needed.

IMPORTANT: Cap mounting nuts MUST be loosened before adjusting wear pads.

5. Tighten pad adjusting bolts, back off, and then torque wear pads to 10 ft-lb (13.6 N-m). Hold adjusting bolt from

turning and torque hex jam nuts to 200 ft-lb (271.1 N-m).

6. Operate to full height on post and recheck for zero clearance.

WEAR PAD FIELD REPLACEMENT/ADJUSTMENT

NOTICE

Over tightening wear pads will cause premature wear and excessive

hydraulic lift pressures. Check wear pad type when replacing or

adjusting. Torque wear pads to 10 ft-lb (13.6 N-m). Do not over tighten

wear pads.

Wear pad

Pad holder

Replace if less than ⅛"

Post

Cap

Wear pad

Pad holder

Wear pad

Adjusting bolt

and hex jam nut