Finger pickup seed meter inspection/adjustment, Finger pickup seed meter inspection/adjustment -12 – Kinze 3600 Lift and Rotate Planter (70 CM) Rev. 5/14 User Manual

Page 116

M0249-01

Model 3600

6-12

Rev. 7/13

TM

Lubrication and Maintenance

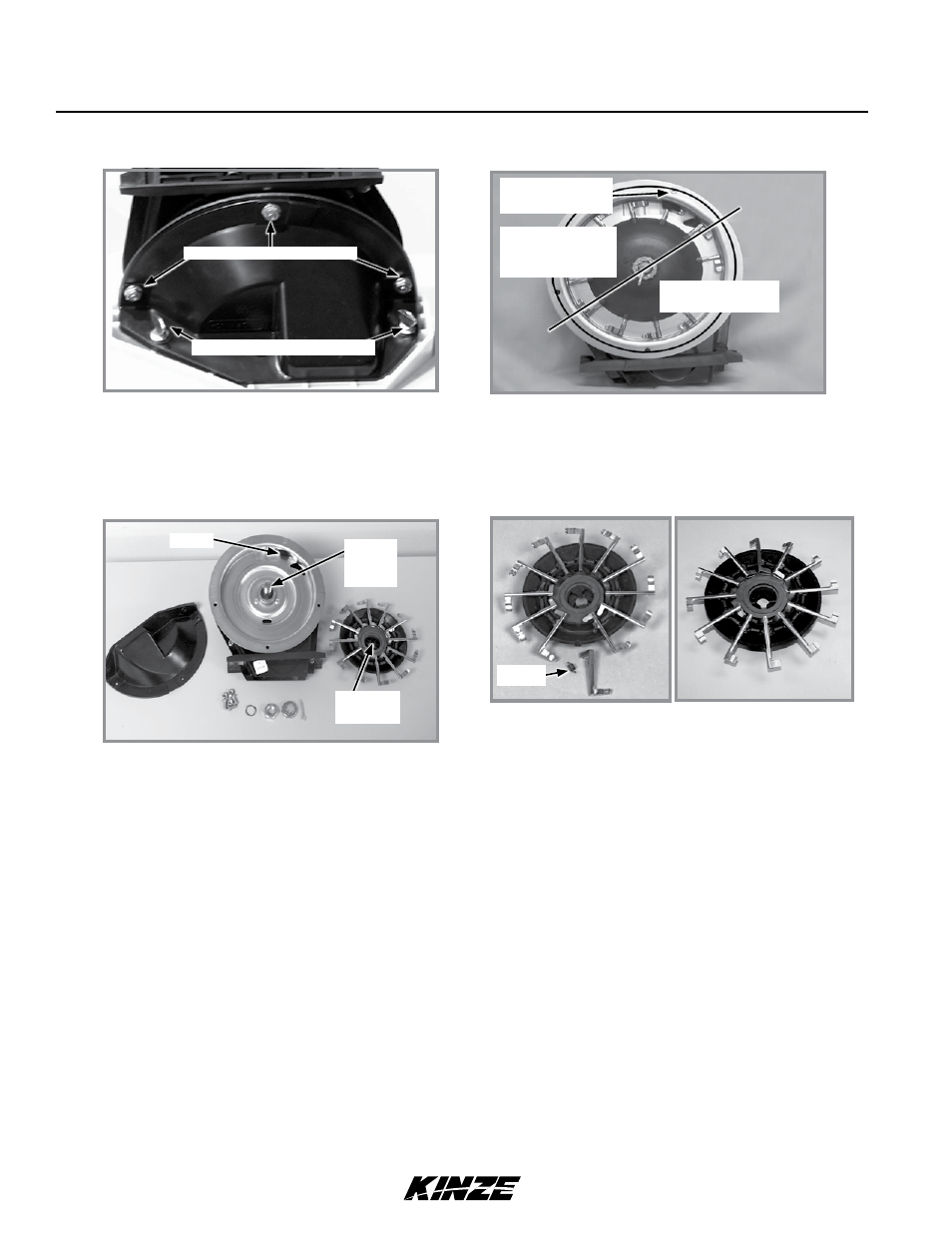

1. Remove two thumbscrews and meter from seed hopper and remove three cap screws and baffle from meter

assembly.

2. Rotate seed meter drive by hand to ensure springs are holding tabs of fingers against carrier plat and fingers

raise in correct area as shown in above photo.

Finger tabs should

raise in this area.

Finger tabs should

contact carrier

plate in this area.

Brush

Notch in

bearing

housing

Projection

on cam

Corn Finger Assembly

(Position Spring Opening

Toward Holder)

Oil Sunflower Finger

Assembly

Spring

Baffle attachment to meter.

Meter attachment to hopper.

FINGER PICKUP SEED METER INSPECTION/ADJUSTMENT

Brush attachment

screw

Buildup of debris or chaff may prevent proper finger operation and requires disassembly and cleaning of finger pickup meter.

1. Remove cotter pin, cover nut and adjusting nut and wave washer (If applicable) from drive shaft.

2. Carefully lift finger holder with fingers and cam off shaft and clean.

3. Check brush for wear and replace if necessary or after every 41 hectares (100 acres) per row of operation

(Approximately 324 hectares (800 acres) of corn or sunflowers on a 8 row machine or 486 hectares (1200

acres) on an 12 row machine).

NOTE: It is not necessary to remove finger holder to replace brush.

4. Remove springs from fingers and remove finger from holder by lifting it out of friction fit slot. Life expectancy of

these parts is about 243-364 hectares (600-900 acres) per row of operation under average conditions.

5. Reassemble meter in reverse order after cleaning and replacing defective parts. Make sure open end of spring

loop is toward inside of finger holder when replacing fingers.

6. Install fingers in holder so holder is flush with carrier plate when assembled. A cam projection aligns with a mating

notch in bearing housing to ensure proper operation when assembled.

Removing meter and baffle

Proper finger operation

Finger pickup meter parts