Chapter 1 introduction and specifications, 1 introduction, Chapter 1 – INFICON UHV Bakeable Sensor User Manual

Page 9

1 - 1

PN

07

4-

15

4N

UHV Bakeable Sensor Operating Manual

Chapter 1

Introduction and Specifications

1.1 Introduction

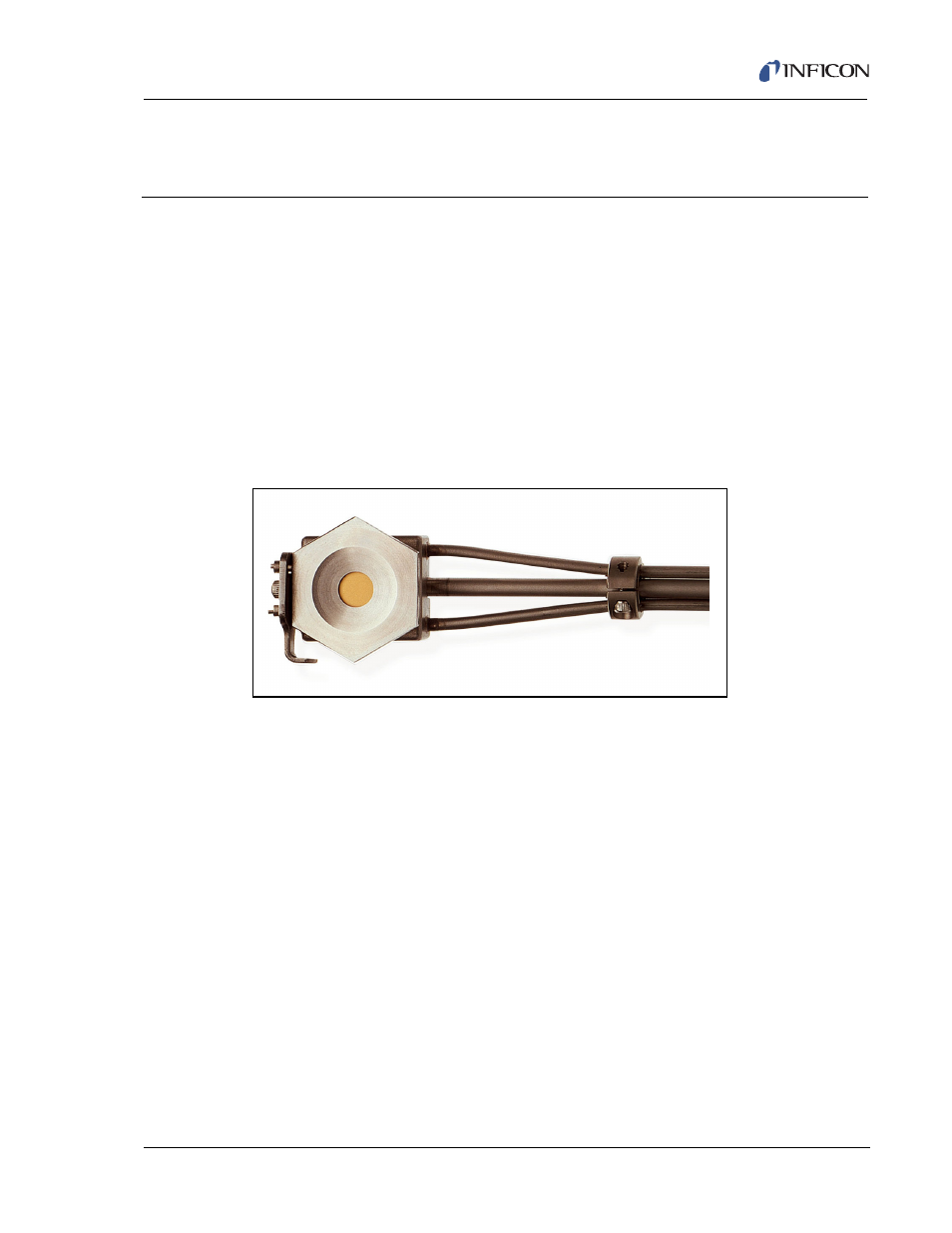

The INFICON UHV Bakeable Sensor (see

) is designed to withstand

continuous bakeout temperatures up to 450°C (for bakeout only, water flow

required for actual deposition monitoring). The front load design allows for easy

insertion of the crystal holder in applications lacking sufficient room for side

insertion. All UHV Bakeable Sensors are welded to a CF40 (2-3/4 in. ConFlat®)

feedthrough. Sensor length must be specified in a sensor length specification form

provided by INFICON, which must be completed when ordering the UHV Bakeable

Sensor.

Figure 1-1 UHV Bakeable Sensor

The UHV Bakeable Sensor is available in a standard configuration where the water

tubes are parallel to the crystal face.

Optionally, sensors can be ordered with a pneumatically driven crystal shutter to

protect the crystal during source warm up, when not used during deposition of an

alternate material, or to extend crystal life when used with RateWatcher™ or rate

sampling.

NOTE: Maximum bakeout temperature for sensors with the optional crystal shutter

is reduced to 400°C.

The exposed crystal electrode is fully grounded to effectively eliminate problems

due to RF interference.