INFICON UHV Bakeable Sensor User Manual

Page 26

2 - 6

PN

07

4-

15

4N

UHV Bakeable Sensor Operating Manual

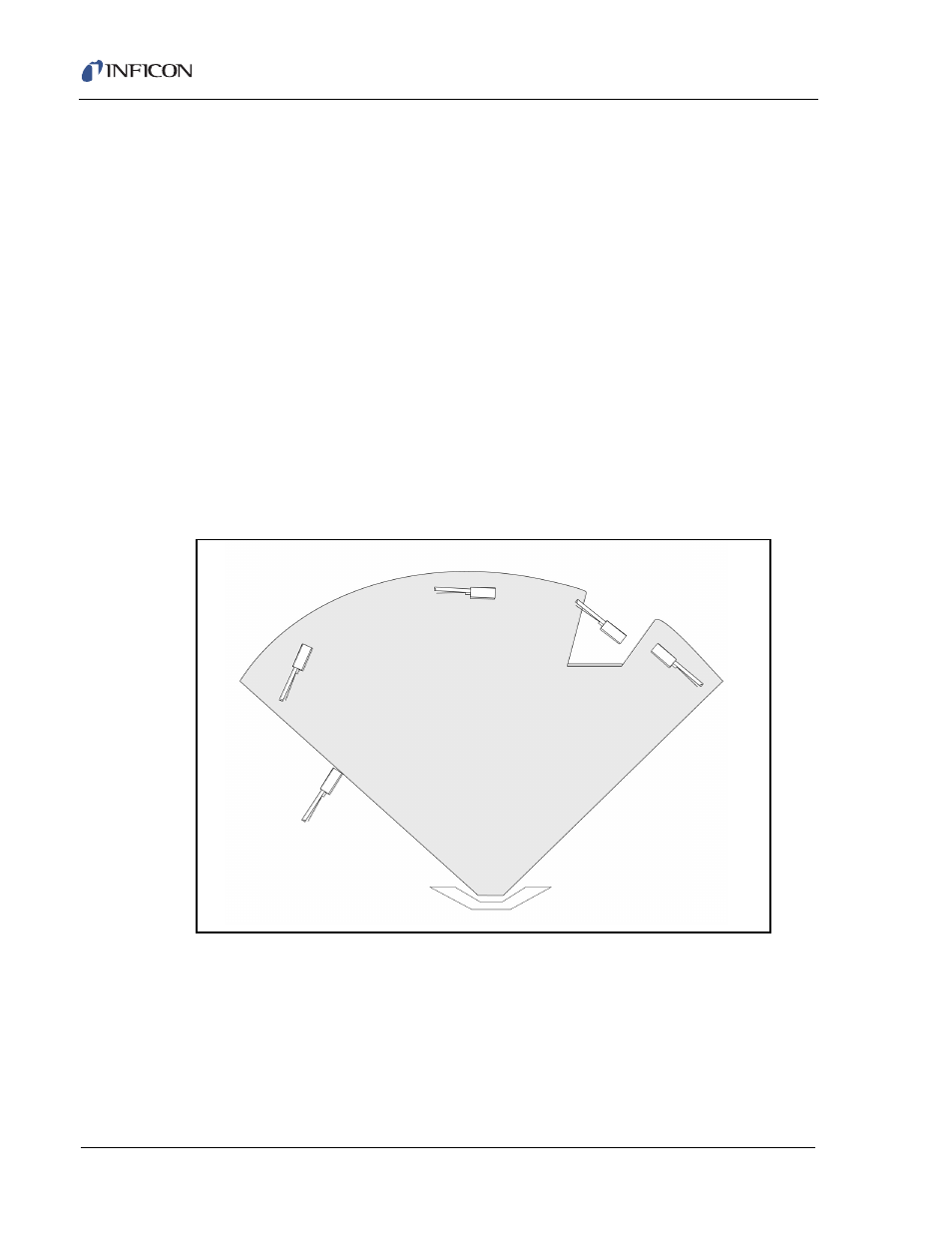

The sensor head must be installed such that the face of the crystal is perpendicular

to the evaporant stream from the source (see

). Two effects may arise if

the sensor head is not perpendicular to the evaporant stream, and the combination

of these effects will have a negative effect on crystal life and increase the

probability of mode hops:

The deposit will not be even across the crystal surface. The edge of the crystal

that is angled away from the source is farther away from the source and

receives less material, causing the thickness of the deposit to become wedge

shaped. This wedge shape in the deposited film tends to reduce the activity of

the crystal at its primary resonance.

The area of the deposit shifts from the center of the crystal. This is due to the

shadowing effect of the crystal aperture. If the crystal is not square to the

evaporant stream, the strength of spurious (non-thickness shear) modes of

vibration are enhanced. If the activity of these spurious modes of oscillation

become strong enough, they cause short-term perturbation of the fundamental

frequency. If they get very strong, the oscillator can lock onto the spurious

mode of oscillation, causing a mode hop.

Figure 2-2 Sensor installation guidelines

To guard against spattering, use a source shutter to shield the sensor during initial

soak periods. If the crystal is hit with only a very small particle of molten material,

it may be damaged and stop oscillating. Even in cases when it does not completely

stop oscillating, the crystal may immediately become unstable, or shortly after

deposition begins, instability may occur.

Correct

Incorrect

Correct

Incorrect

Incorrect

Obstruction

Source