Chapter 5 troubleshooting, 1 troubleshooting tools, 1 symptom, cause, remedy – INFICON UHV Bakeable Sensor User Manual

Page 45: Chapter 5

5 - 1

PN

07

4-

15

4N

UHV Bakeable Sensor Operating Manual

Chapter 5

Troubleshooting

5.1 Troubleshooting Tools

If the UHV Bakeable Sensor fails to function, or appears to have diminished

performance, diagnose the sensor using one or more of the following:

Symptom, Cause, Remedy chart (see

Diagnostic Tools (see

)

Digital Multimeter (see

5.1.1 Symptom, Cause, Remedy

The Symptom, Cause, Remedy chart can help identify the causes of, and solutions

to, sensor problems and related issues (see

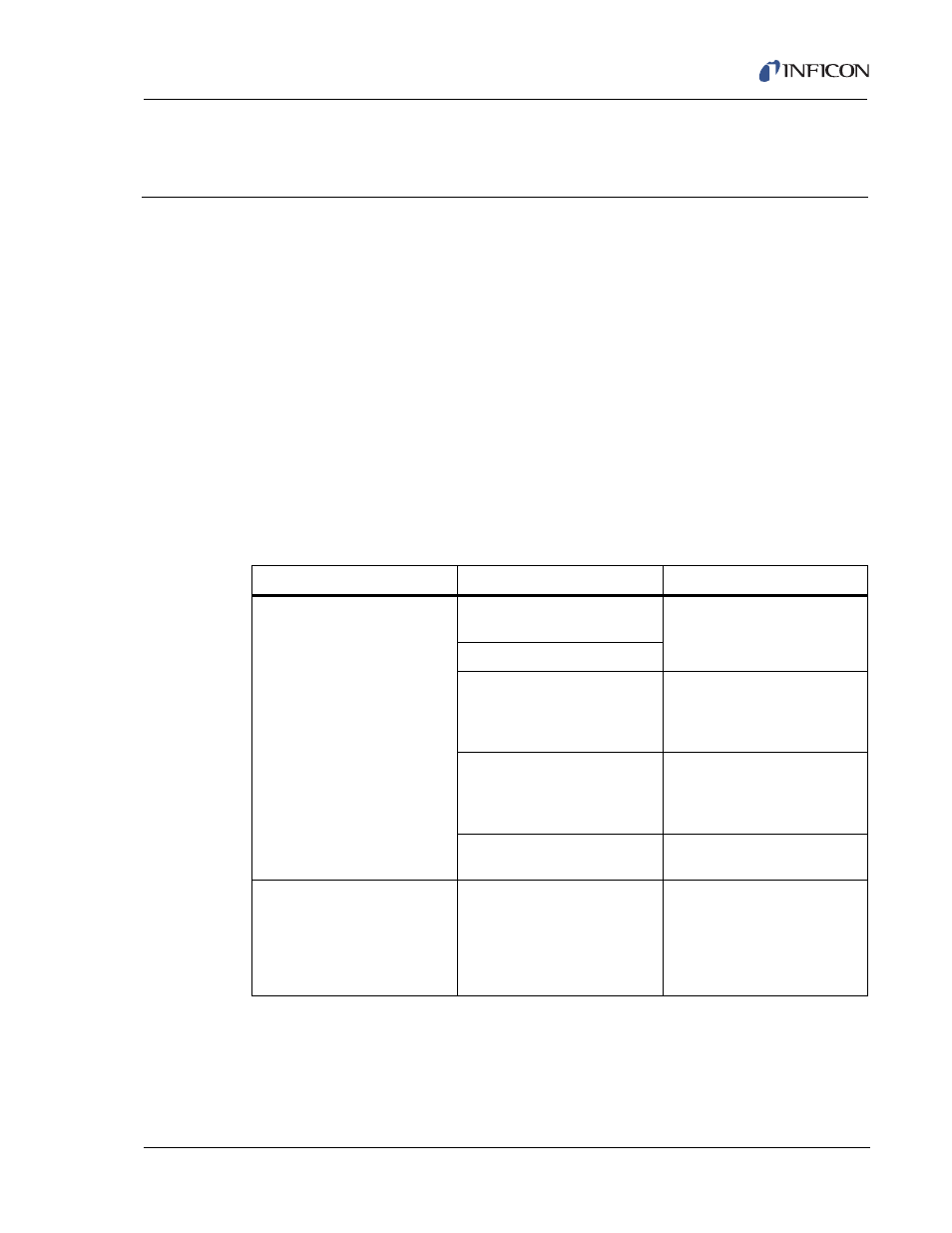

Table 5-1 Symptom, Cause, Remedy

SYMPTOM

CAUSE

REMEDY

Large jumps of thickness

reading during deposition.

Mode hopping due to damaged

or heavily damped crystal.

Replace the crystal.

Crystal is near the end of its life.

Scratches or foreign particles on

the crystal holder seating

surface.

Clean or polish the crystal

seating surface of the crystal

holder (refer to

Uneven coating.

Mount the sensor with the

crystal face perpendicular to the

evaporant stream (refer to

Particles on the crystal.

Remove source of particles and

replace the crystal.

Crystal ceases to oscillate

during deposition before it

reaches its “normal” life.

Crystal is being hit by small

droplets of molten material from

the evaporation source.

Use a shutter to shield the

sensor during initial period of

evaporation.

Move the sensor farther from the

source.