INFICON UHV Bakeable Sensor User Manual

Page 47

5 - 3

PN

07

4-

15

4N

UHV Bakeable Sensor Operating Manual

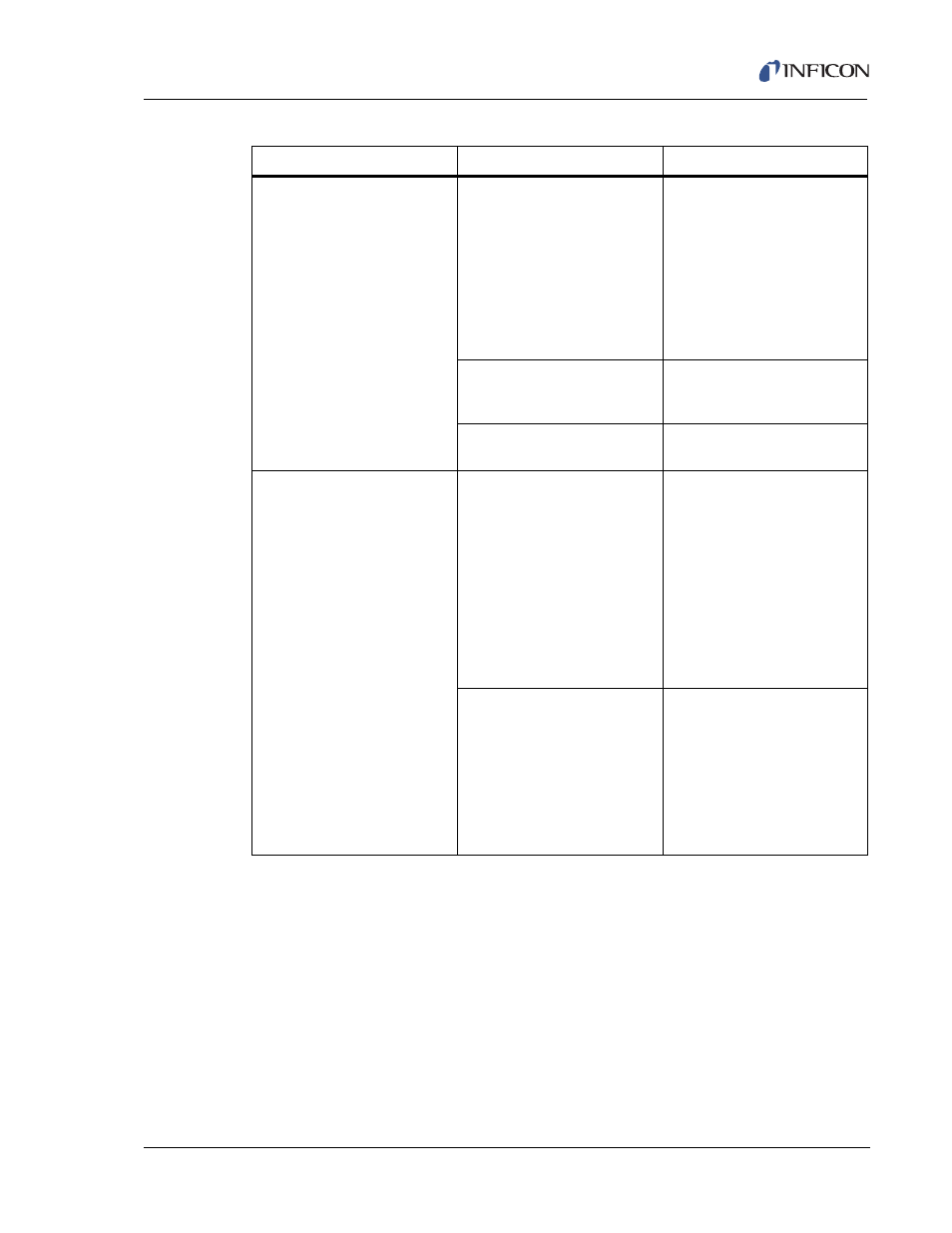

Thermal instability: large

changes in thickness reading

during source warm-up (usually

causes thickness reading to

decrease) and after the

termination of deposition

(usually causes thickness

reading to increase).

Excessive heat applied to the

crystal.

If heat is due to radiation from

the evaporation source, move

sensor farther away from source

and use Low Thermal Shock

crystals (PN SPC-1157-G10) for

better thermal stability.

If the source of crystal heating is

due to a secondary electron

beam, use a sputtering sensor.

No cooling water.

Water flow rate is low.

Water temperature too high.

Check cooling water flow rate.

Heat induced from electron flux. Use sputtering head for

non-magnetron sputtering.

Poor thickness reproducibility.

Erratic source emission

characteristics.

Move sensor to a different

location.

Check the evaporation source

for proper operating conditions.

Ensure relatively constant pool

height and avoid tunneling into

the melt.

Use multiple sensor option if

available on controller.

Material does not adhere to the

crystal.

Check the cleanliness of the

crystal.

Use gold or silver or alloy

crystals, as appropriate.

Evaporate an intermediate layer

of proper material on the crystal

to improve adhesion.

Table 5-1 Symptom, Cause, Remedy (continued)

SYMPTOM

CAUSE

REMEDY