Section 1.4.1 – INFICON UHV Bakeable Sensor User Manual

Page 12

1 - 4

PN

07

4-

15

4N

UHV Bakeable Sensor Operating Manual

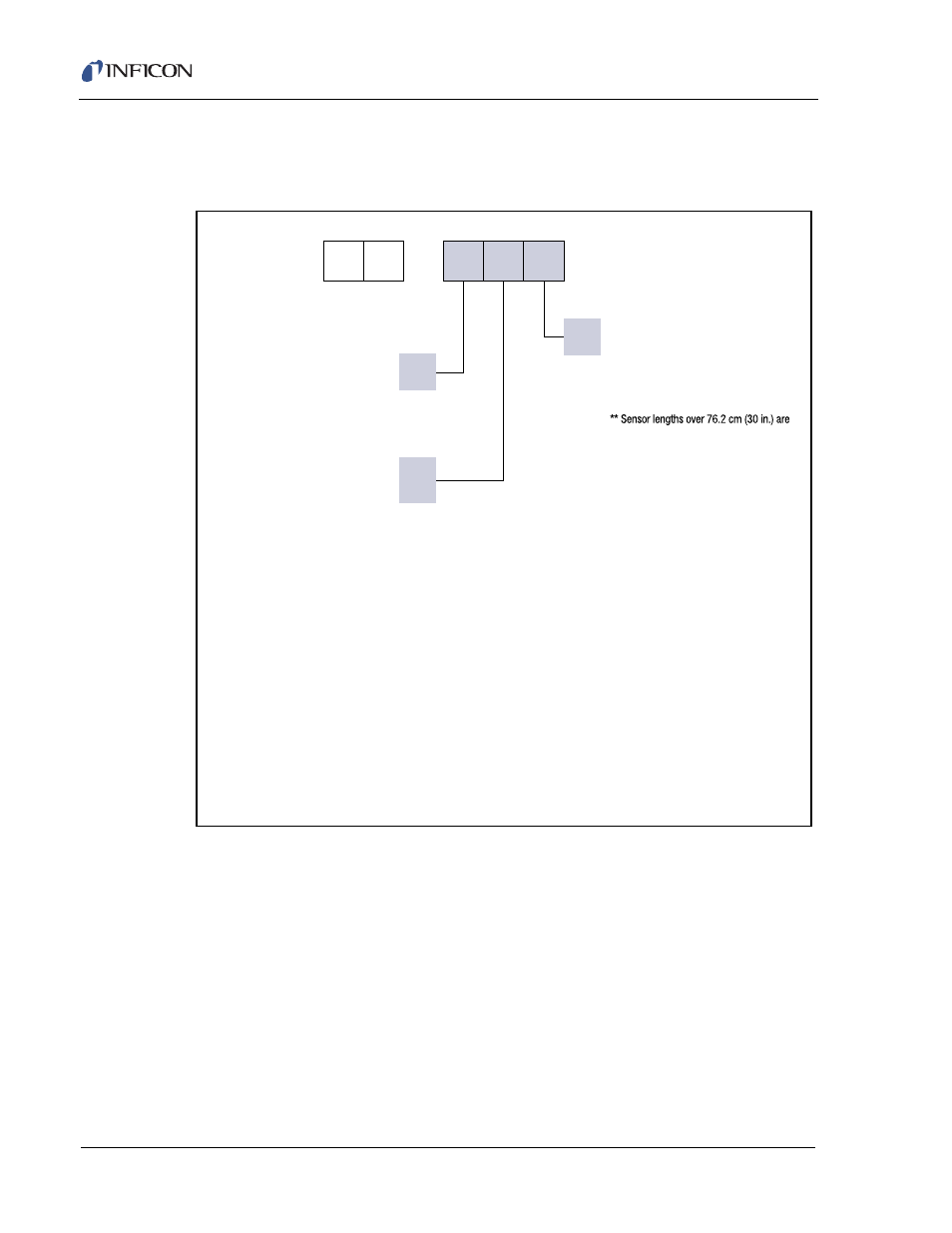

1.4.1 UHV Bakeable Sensor Configuration Overview and Parts

UHV Bakeable Sensor . . . . . . . . . . . . . . BK-AXF (see

)

Figure 1-2 UHV Bakeable Sensor configurations

Thin Film Manuals CD . . . . . . . . . . . . . . . . . . . . . . . PN 074-5000-G1

Crystal Snatcher. . . . . . . . . . . . . . . . . . . . . . . . . . . . PN 008-007

Molybdenum Disulfide in Isopropyl Alcohol . . . . . . . PN 750-191-G1

Graphite in Isopropyl Alcohol

(provided only with shuttered sensors) . . . . . . . . . . PN 009-175

F

0

1

B K –

A

NOTE 1:

Orders cannot be entered without a completed sensor length

specification form (provided by INFICON). Once order is confirmed,

it cannot be canceled.

NOTE 2:

Sensor lengths are measured from the center of the crystal to

the vacuum side (sealing surface) of the feedthrough (see length

specification form).

NOTE 3:

All UHV Bakeable Sensors are welded to a CF40 feedthrough.

NOTE 4:

Shutter air tube is connected to the feedthrough tube using a

VCR® fitting.

Type of Sensor

(crystals sold separately)

Standard

(water lines parallel to crystal face)

Shutter Assembly

None

Standard shutter

Length of Sensor

Standard length –

Shuttered sensors

From 17 to 101.6 cm (6.7 to 40 in.)

Non-shuttered sensors

From 10.2 to 101.6 cm (4 to 40 in.)

subject to an additional charge, as well

as 2-4 weeks additional lead time.