Working modes, Vacuum mode, Fig. 4-6 – INFICON UL1000 Helium leak detector User Manual

Page 45: 3 working modes, 1 vacuum mode

Description and Working Principle

45

iina

70

e 0

4

.f

m

te

chn

ica

l ha

nd

boo

k

(1

40

8)

4.3

Working Modes

4.3.1

Vacuum Mode

As mentioned (Please refer to Chapter

) the sample has to be

evacuated to allow Helium which is sprayed on the outside to enter through any leaks

due to the pressure difference.

When pressing the

Valves V1a and V1b open and the sample is

pumped down by the roughing pump (UL1000) or scroll pump (UL1000 Fab). At the

same time valve V2 is closed to avoid an unacceptable pressure increase in the turbo

pump and the mass spectrometer. With valve V2 being closed the turbomolecular

pump is operated without being backed up by the scroll pump. Since the mass

spectrometer is already under vacuum no further gas is pumped. Thus the pressure

p

2

remains constant or increases only slowly.

If the pressure p

2

even though increases (e.g because of a very long pumping down

process), then the evacuation will be broken (V1a and V1b closed) at p

2

> 10 mbar

and V2 will open shortly to restore an appropriate foreline (p

2

< 1 mbar).

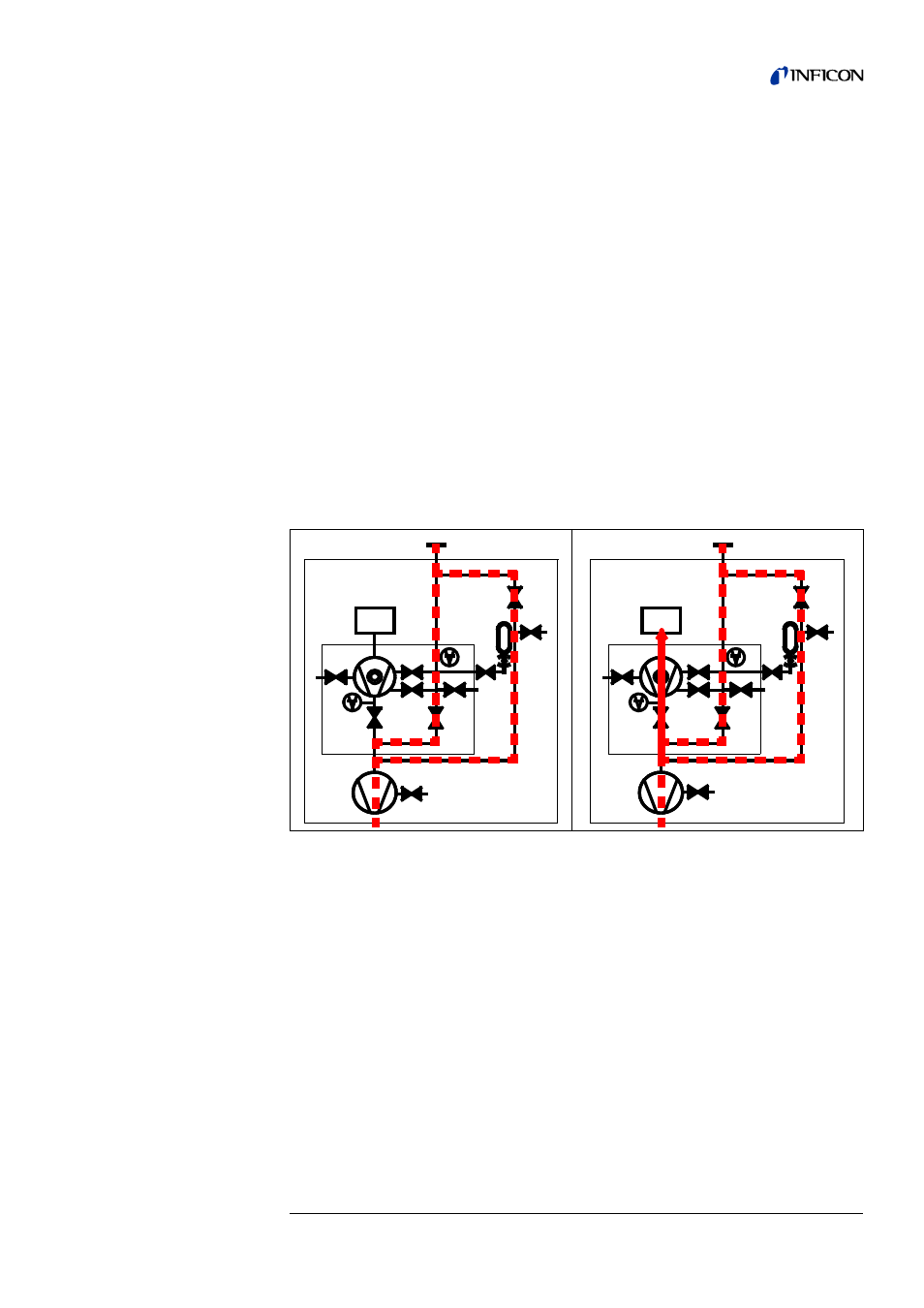

The following diagrams show the gas flow during evacuation and during the modes

GROSS, FINE and ULTRA.

The condition for the evacuation process described is maintained until the inlet

pressure p

1

has dropped below 15 mbar. Now valve V2 opens. Possibly present

helium may now flow upstream against the pumping direction of the turbo molecular

pump into the mass spectrometer where it is detected. This mode is called GROSS,

the detection limit is 1×10

-6

mbar l/s.

Fig. 4-6: left: Evacuation (no measurement), right: GROSS Mode

V4a

V4b

p

2

V2

MS

V6

V7

p

1

V1b

V1a

V5

TL

V8

V5

V4a

V4b

p

2

V2

MS

V6

V7

p

1

V1b

V1a

V5

TL

V8

V5