Notes refering the maintenance of the splitflow 80, Description of the maintenance work, 6 description of the maintenance work – INFICON UL1000 Helium leak detector User Manual

Page 104: Danger

104

Maintenance Work

iina

70

e 0

9

.f

m

te

chn

ica

l ha

nd

boo

k

(1

40

8)

Scroll module Agilent TS 620 will have to be replaced. For the D16 B in the UL1000

a refurbishment will be necessary.

Approximately 10.0 hours will be needed for this maintenance work, in case that

SplitFlow 80 was exchanged.

9.5.5

Notes refering the maintenance of the SplitFlow 80

To lubricate the ball bearings, the turbo molecular pump SplitFlow 80 is filled with and

operating fluid. Replace the operating fluid every 3 years, no matter for how many

operating hours the turbo pump has been operated. The operating fluid reservoir

should be replaced by an INFICON authorized person or service technican.

Under high load operating conditions or when used in connection with processes

involving contamination, shorter replacement intervals need to be selected.

If the turbopump should be shut down for longer than a year the operating fluid

reservoir must be changed first.

The recommended bearing exchange of the SplitFlow 80 is 4 years, no matter for

how many operating hours the pump has been used. The replacement of the pump

is recommended for those customer, who has to guarantee a 100% up-time for the

unit. In this case the turbopump SplitFlow 80 will be replaced by a refurbished pump.

9.6

Description of the Maintenance Work

Modifications to the UL1000 and UL1000 Fab/UL1000 which exceed the scope of

normal maintenance work must only be performed by trained personnel.

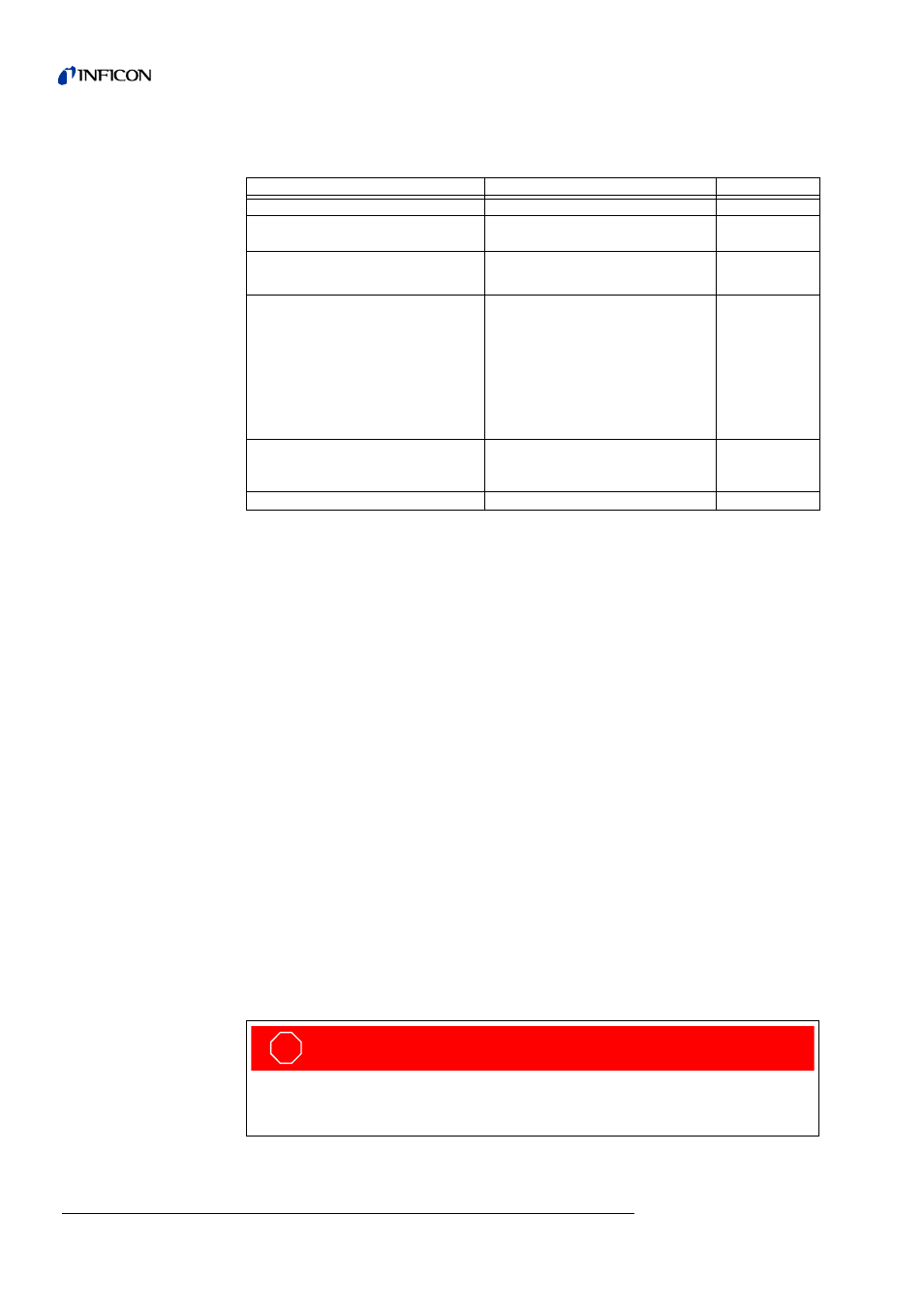

Work to be done

Required materials

Part No.

Replace scroll head (Agilent TS 620) Scroll head for Agilent TS 620

200001665R

Refurbish D16 backing pump

(UL1000 only)

Refurbished D16 B backing pump

Disassemble/clean the valve block

Replace the valve seals

Seal kit for valve block

Seal kit for valves

200000593

200000594

Check/replace filter

Replacement filter cell for fan

Replacement filter for venting and

purge gas line

Silencer for exhaust (UL1000 Fab

only)

Oil filter insert (10 pcs.) UL1000

only

200000685

200000683

20099183

200000694

Preventive exchange of the SplitFlow

80 after 3 years, without limitation of

operating hours. Please refer to

Refurbished turbopump SplitFlow

80.

200003800R

Test and alignment

STOP

Danger

The protective ground conductor distributor screw at the bottom of the chassis must

not be loosened. If the protective ground conductor connection is not in place, the

operator will not be protected against electric shock.