INCRA Jig User Manual

Page 8

8

Rout a test groove

NOTE: The following instructions apply to Dovetails AND Box Joints.

After setting your router bit depth of cut, you will position your INCRA Jig and

install the joinery template. This is accomplished through a setup operation

called “centering”. Centering locates your INCRA Jig so that the router bit is

aligned with the center of the stock width you select. Once you find the center,

install the joinery template and you’ll be ready to cut a perfect joint. The simple

steps to follow should always be used when setting up for joint making.

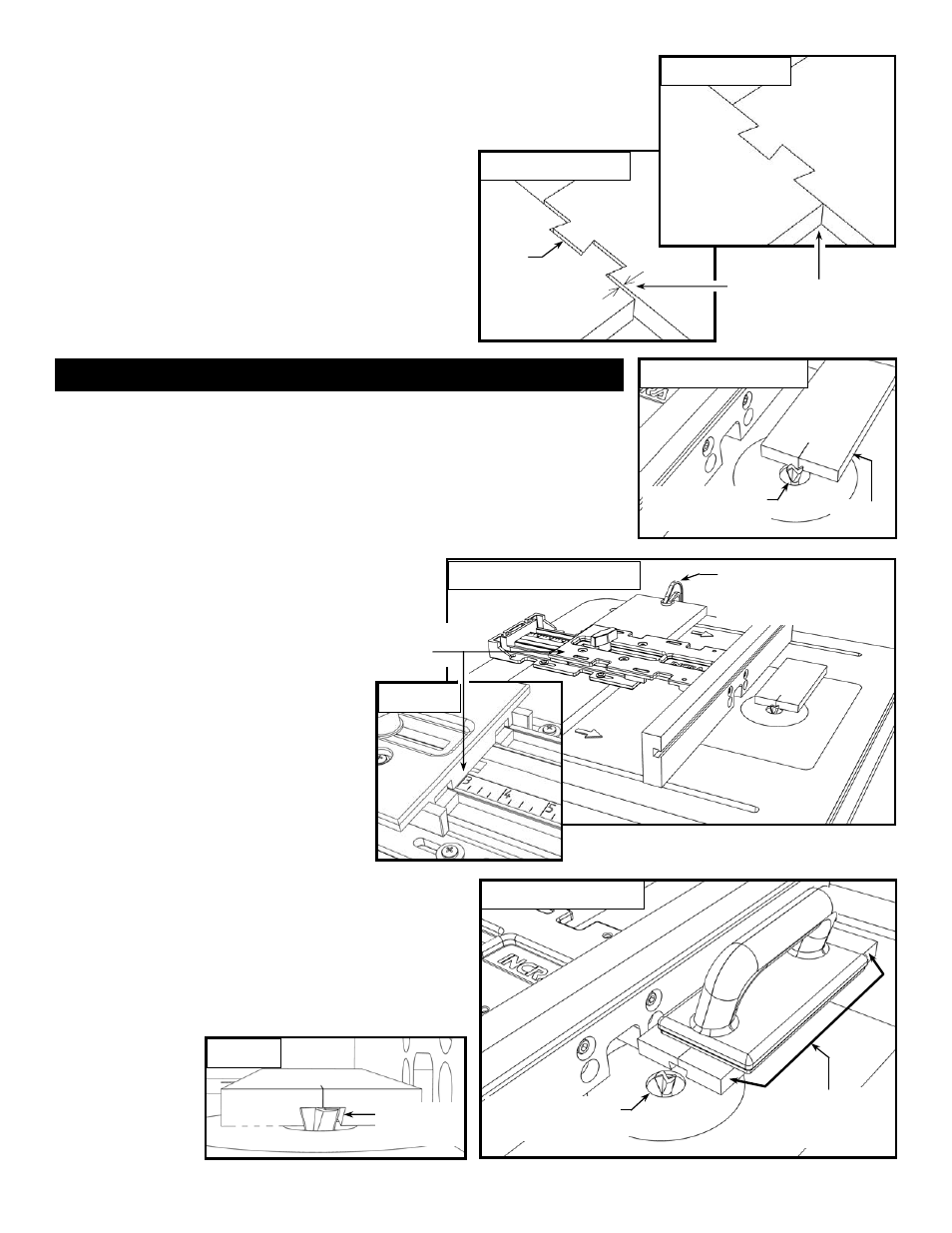

Begin by cutting a piece of 3/4” thick stock to the same

width as the boards you wish to join later on. Mark the

center of this board’s width on one end and place the

board face down on the router table with the

center of the board aligned with the

approximate center of the bit, Fig. 29.

Set your INCRA Jig to 3” on the scale and

tighten the clamping knob. Then loosen the

clamps that secure the base panel, and slide

it forward until the fence contacts the edge of

the board. Make sure the center mark on the

board is still aligned with the approximate

center of the bit, then re-tighten the clamps,

Figs. 30 and 30A.

Turn the router on, and using a good rubber

soled push block, cut a groove along the

entire length of the board, Fig. 31. Now turn the stock end

for end and make a second pass over the router bit. The

second pass should widen the groove slightly (unless you

are already perfectly centered). Make sure you have turned

the stock end for end before making the second pass. (This

places the center mark at the back of the board.)

With the router off, turn the cutter to it’s widest profile. Slide

the test board against the fence to rest just over the cutter.

There should be a

small gap between

the edge of the bit

and one side of the

groove, Fig. 32.

Unclamp the two boards and test the fit by joining them as

shown in Fig. 27. As with any dovetail jig, a little trial and

error is needed to achieve a snug fitting joint. To tighten

the fit, raise the bit up slightly; to loosen the fit, lower the

bit slightly. Just remember this phrase: “Heighten to

tighten, lower to loosen”. After adjusting the bit height,

make a new set of trial cuts on a fresh uncut corner of the

boards. After a few adjustments and trial cuts, you’ll have

a perfect fit.

Tip: When the fit is too loose, the trial cuts provide a

gauge to let you know how much to raise the bit. Just join

the trial pieces end to end and gently pull the boards to

wedge the dovetails apart, Fig. 27. The gap that appears

is equal to the distance you need to raise your dovetail bit

to achieve a tight fit, Fig. 28.

Fig. 27

Fit is too loose

Fig. 28

Perfect fit

Raise the bit

this much . . .

Gap

Heighten to tighten

Or

Lower to loosen

. . . to produce a

perfect fit

First: Lock upper

body to 3”

Second: Loosen clamps and slide base

panel forward until fence contacts

edge of centering board

Fig. 30

Set initial fence position

Fig. 29

Align board with bit

First: Rout a groove along the

entire length of the stock

Second: Rotate board end-

for-end and make a second

pass over the bit

Fig. 30A

Fig. 31

Rout test groove

3/4” stock

Align center of board with

approximate center of bit

Centering the router bit on your workpiece

Fig. 32

Small gap on one

side of the bit