INCRA Jig User Manual

Page 10

10

Tip: After making your first series of

pin cuts, check the fit with one of your

tail boards. If the tail board won’t fit

all the way into the pin board, just

measure the distance it protrudes,

Fig 38A. This is the distance you

need to move the stop away from the

bit to achieve a flush fit.

Pin Cuts

Move the INCRA Jig to the first pin cut on the template that will position the

cutter outside the fence. Since the pin sockets are stopped cuts, bring the

stop positioner just up to the outside diameter of the cutter and clamp in

place, Fig. 37. This stop setup will always (and intentionally) produce a

socket that is just a little short, so we’ll only cut one end of one piece

at this time, then adjust as necessary. Using a rubber soled push

block, move the stock into the cut until you just touch the stop. Don’t

force the material against the stop. Now move the fence from one pin

cut to the next until you have cut across the full width of your material, Fig.

38. After making the cuts, check the fit between this board and one of the

tail boards. Adjust

the stop position

as necessary to

control the socket

length for a

perfect, flush fit

(See Tip and Fig.

38A at right).

Now make the

final pin cuts on

both ends of both

boards.

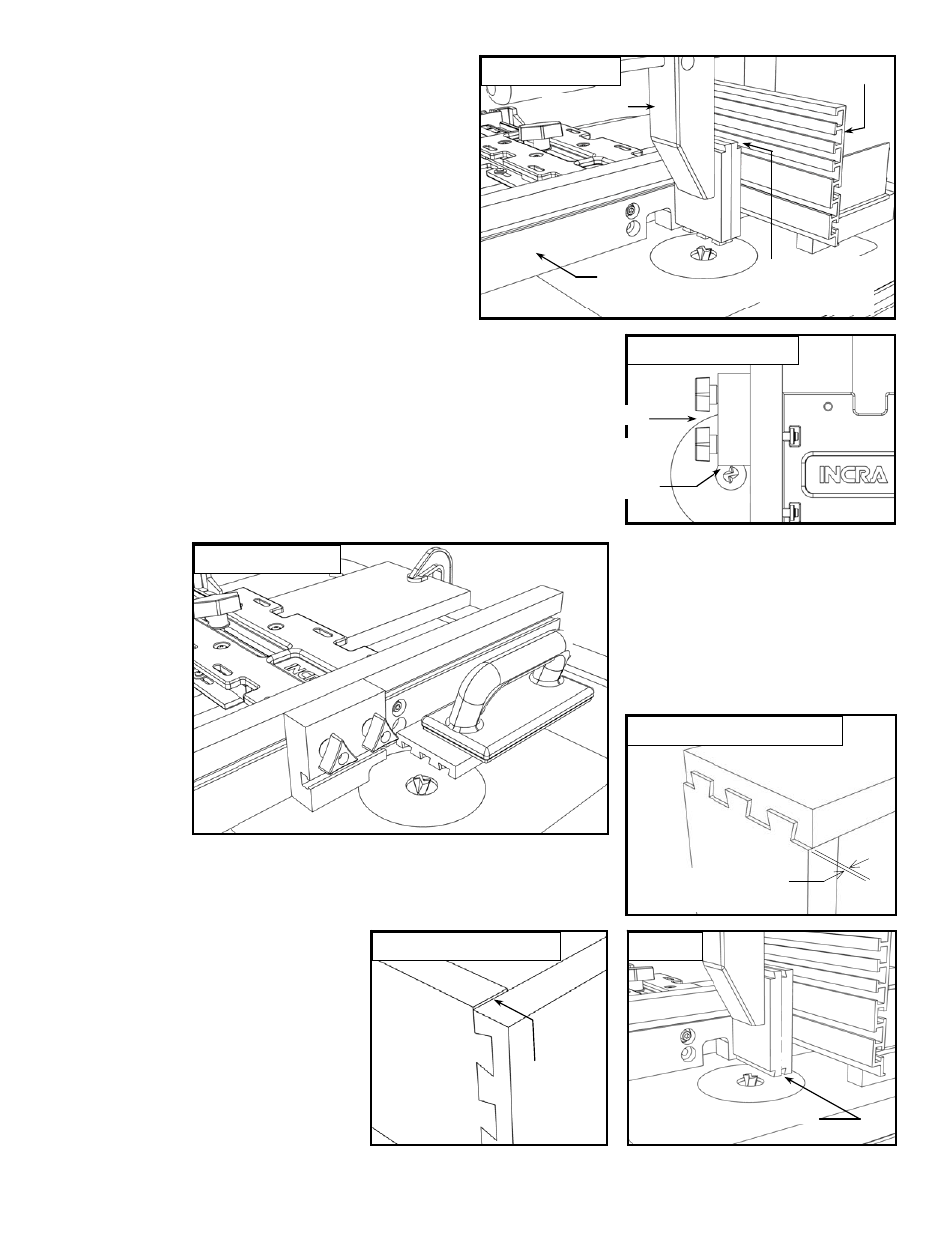

Fig. 36

Cut the tails

Fence

Right angle fixture

Handscrew clamp

Fig. 37

Set stop positioner

Position stop as close as

possible to the outfeed

side of the bit

Stop positioner

Clamp two tail boards

with rabbets facing

outward as shown

Tail Cuts - Continued

Now, clamp the two tail boards to your Right Angle

Fixture as shown in Fig. 36 and make the tail series of

cuts. The first cut for any tail board will always remove

the edge of the stock. To keep this first cut clean and

splinter-free, it’s a good idea to return to a 1/32” scoring

pass, then sneak up to the first visible mark on the

template in one or two passes. The first visible mark

determines which cut lines to use on the template for the

remainder of the tail cuts. If the first mark is a “B” cut for

example, simply move the INCRA Jig from one “B” cut to

the next “B” cut until you have cut across the full width of

your material. After completing the cuts, flip the boards

end for end and repeat.

Tail board

Pin board

Fig. 38A

Pin cuts - final adjustment

Move stop block this far back

to achieve a flush fit

Beginner’s Tip

After making a half blind dovetail, you may notice that the joint looks

symmetrical, but the edges of the two boards do not align flush, Fig. 39. This

simply means that when you centered your material as described on page 8,

you were close but not quite perfect. Of

course practice DOES make perfect, but

there is another method for cutting the tail

boards that will ensure a flush alignment

regardless of how well your board was

centered. Just make sure when you clamp

the tail boards to the Right Angle Fixture

that the dovetail shaped rabbets on all of

the boards face the cutter, Fig. 40. That’s

all it takes! Remember that even if you use

this procedure, you should still center first to

ensure a symmetrical looking joint.

Boards not flush

Fig. 39

Tail cuts - beginner’s tip

Fig. 40

Dovetail shaped rabbets face cutter

Fig. 38

Pin cuts - final