Applications - common cuts – INCRA Jig User Manual

Page 6

6

Grooving, dadoing, rabbeting and edge forming.

Box joints, dovetails and the exotic INCRA Double and Double-Double joinery may be the icing on the

cake, but everyday cutting applications such as grooving, dadoing, rabbeting and edge forming are the

real bread and butter benefits of owning an INCRA Jig. Each of these common cutting operations requires

a different way of calibrating the fence to the

cutter. For grooving and dadoing, you will

typically zero the fence to the INSIDE edge

of the router bit. For rabbeting, you will zero

the fence to the OUTSIDE edge of the bit.

And for edge forming, you will often add a

pair of sub fences to accommodate the

larger diameter of most edge forming bits.

A quick look at the illustrations below will

show how you can quickly and easily

calibrate your INCRA Jig for each of these

types of cuts.

Applications - Common Cuts

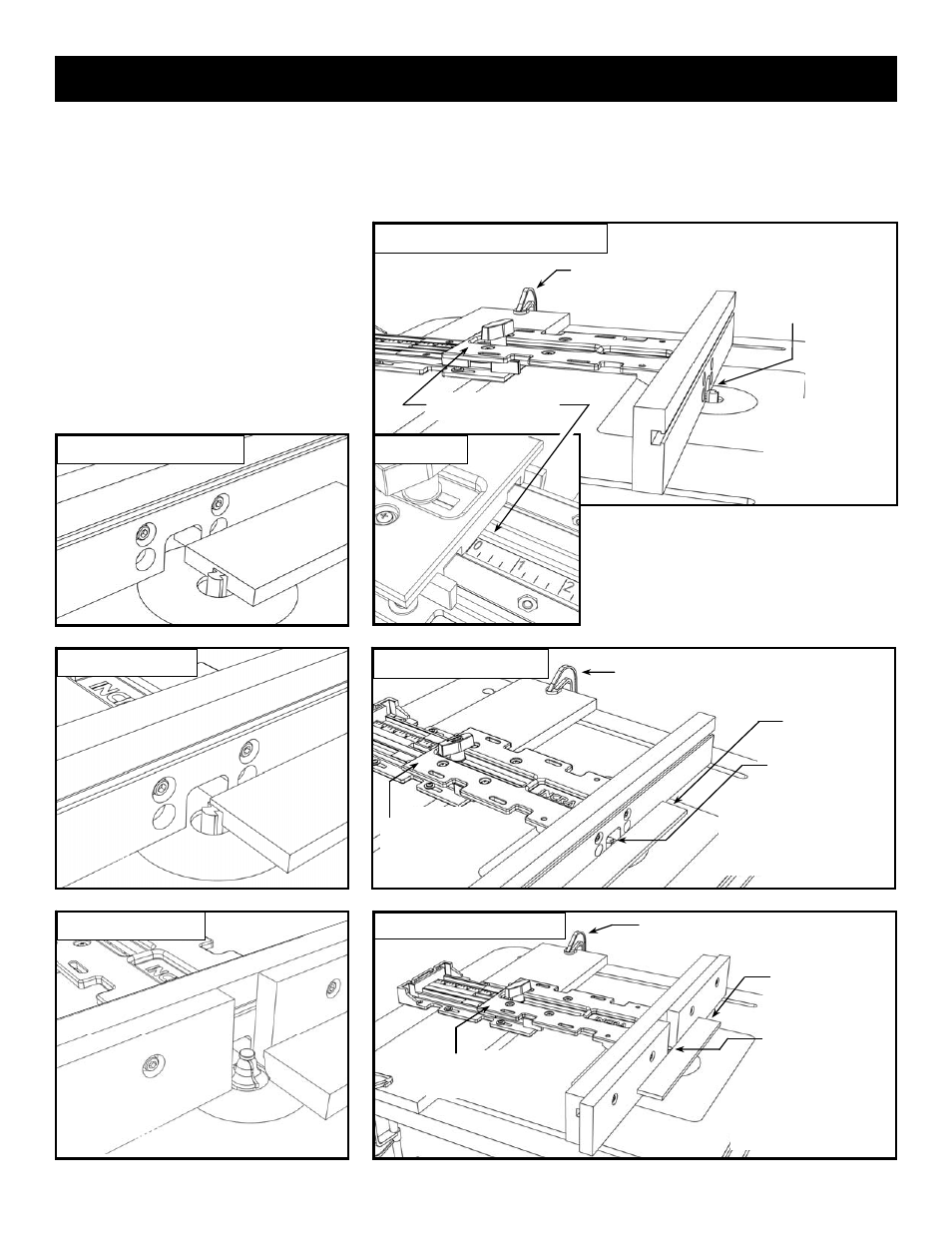

Fig. 22

Edge forming

First: Lock upper body at 0”

Second: loosen clamps and

slide base panel forward

towards the cutter

Third: While continuing to nudge

the base panel forward, sight

along the fence until the gap of

light between the fence and the

cutter disappears.

Fourth: Re-tighten the base

panel clamps. The fence is

now zeroed to the inside edge

of the cutter

Fig. 19A

Fig. 19

Zeroing for grooving and dadoing

Fig. 21

Zeroing for rabbeting

First: Lock upper

body at 0”

Fig. 18

Grooving and dadoing

Fig. 20

Rabbeting

Fig. 23

Zeroing for edge forming

Third: Hold straight-edge

against fence

Fourth: Tap base panel

backward until cutter “kisses”

the straight-edge

Fifth: Re-tighten the base panel clamps.

The fence is now zeroed to the outside

edge of the cutter

First: Lock upper

body at 0”

Second: Loosen clamps and slide base panel

forward until the fence covers the cutter

When setting up for most common cutting

operations, the first step us usually to set

the INCRA Jig to a reading of zero, as

shown in Fig. 19A. The base panel is

then moved forward until the fence is

“zeroed” to the desired edge of the bit.

Second: Loosen clamps and slide base panel

forward until sub fences cover the cutter

Fourth: Tap base panel

backward until bearing

touches straight-edge

Fifth: Re-tighten the base panel

clamps. The fence is now zeroed to

the cutter bearing

Third: Hold straight-edge

against fence at level of

cutter bearing