Through dovetail – INCRA Jig User Manual

Page 13

13

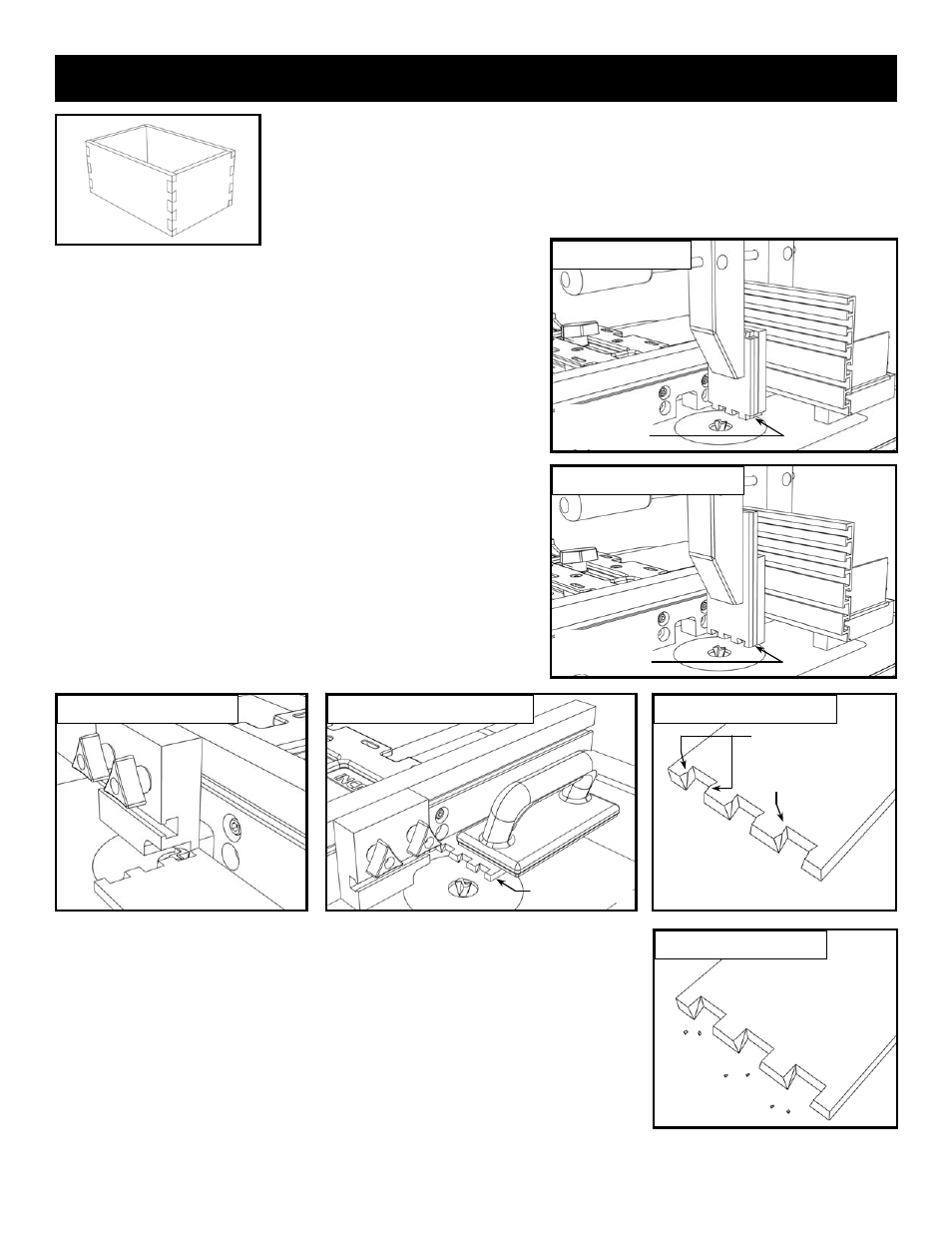

Install the template

After centering as shown on Pages 8 & 9, select and install the

Dovetail Template. (Refer to Page 16 and Figs. 33 & 33A).

Tail Cuts

Clamp the two tail boards to your Right Angle Fixture with a backing

board as shown in Fig. 51 and make the tail series of cuts. Use the

shorter of your stock lengths for the tails. The first cut for any tail

board will always remove the edge of the stock. To keep this first cut

clean and splinter-free, it’s a good idea to start with a 1/32” scoring

pass, then sneak up to the first visible mark on the template in one or

two passes. The first visible mark determines which cut lines to use

on the template for the remainder of the tail cuts. Make the tail series

of cuts across the width of your material. After completing the cuts,

flip the boards end for end and repeat the cuts.

Pin Cuts

After completing the tail cuts, clamp the two long pieces of material to

the Right Angle Fixture with a backing board as shown in Fig. 52 and

make the vertical series of cuts for your pin boards. Remember, if you

used the “B” cuts when cutting the tails, you’ll use the “A” cuts for the

pins and visa versa. After completing the cuts across one end of your

boards, flip the material over and repeat the vertical pin series of cuts.

Now, we’ll repeat the pin series of cuts again. This time with the material face down

on the table. Return your INCRA Jig to the first pin cut on the template. With the

router off, slide one of the pieces to nest the cutter inside the existing cut. You need

to stop the cut just before the cutter contacts the end of the existing cut. Slide a stop

positioner up to the end of the board and clamp in place, Fig. 53. Slide the board

back away from the cutter, turn the router on and using a rubber soled push block,

make the horizontal pin series of cuts on both ends of both boards, Fig. 54.

If you try to assemble your pin and tail pieces at this moment, you would find that a

small triangle of wood blocks the two pieces from sliding together. To complete the

joint, all that you need to do is whittle off this triangle of wood. This can be

accomplished with a pocket knife, a razor knife or a chisel. Just follow the line of the

cut that was started straight back into the corner, Figs. 55 and 56. Now assemble for

a perfect through dovetail.

Through Dovetail

Through dovetails

Through Dovetails

When preparing stock for a through dovetail, always remember that the stock thickness

must be equal to or slightly less than the depth of cut. It is a good idea to FIRST set your

router bit depth of cut as described on page 7 before preparing your stock, since you must

make the stock match the cutter depth. You cannot raise or lower the cutter to match your

stock thickness! Follow the instructions below to add this traditional interlocking joint to

your skills resume.

Fig. 51

Fig. 52

Fig. 53

Cut the tails

Pin cuts - vertical series

Pin cuts - set the stop

Two SHORT sides

with backing board

Two LONG sides with

backing board

Fig. 55

Pin cuts - remove tabs

Whittle off these triangles of

wood from each pin.

Cut straight back to corner

Fig. 56

Completed pin cuts

Fig. 54

Pin cuts - horizontal series

See detail in Fig. 55