Scotch-weld, One-part epoxy adhesives and metal primers, Two-part structural adhesives – HMC Electronics DP100 3M DP-100 Scotch-Weld Epoxy Adhesive User Manual

Page 5

1386

(Cream)

High temperature strength

Impact resistance

150,000

60

350/177

10

10

3,000

5,500

4,500

2,500

1469

(Cream)

High temperature strength

Low viscosity

60,000

120

350/177

10

2

3,150

3,700

3,700

3,600

2086

(Gray)

High temperature strength

High viscosity

Paste

60

350/177

10

5

3,000

5,000

5,000

2,200

2214 Regular

(Gray)

High temperature strength

Low temp curing

Paste

60

250/121

10

5

3,000

4,500

4,500

1,500

2214 Hi-Density

(Gray)

High temperature strength

Deaerated, dense bonds

Paste

60

250/121

10

5

3,000

4,500

4,500

1,700

2214 Hi-Temp

Original (Gray)

High temperature strength and

environmental resistance

Paste

60

250/121

10

2

2,000

2,000

3,000

2,500

2214 Hi-Temp

New Formula (Gray)

High temperature strength and

environmental resistance

Paste

60

250/121

10

2

2,800

2,800

2,800

2,500

2214 Non-Metallic

Filled (Cream)

High temperature strength

Higher insulation value

Paste

60

250/121

10

7

3,000

4,000

4,500

1,500

2290

(Amber)

Low solids liquid coating for

metal laminations

60

30

350/177

50

10

5,000

5,000

3,500

1,200

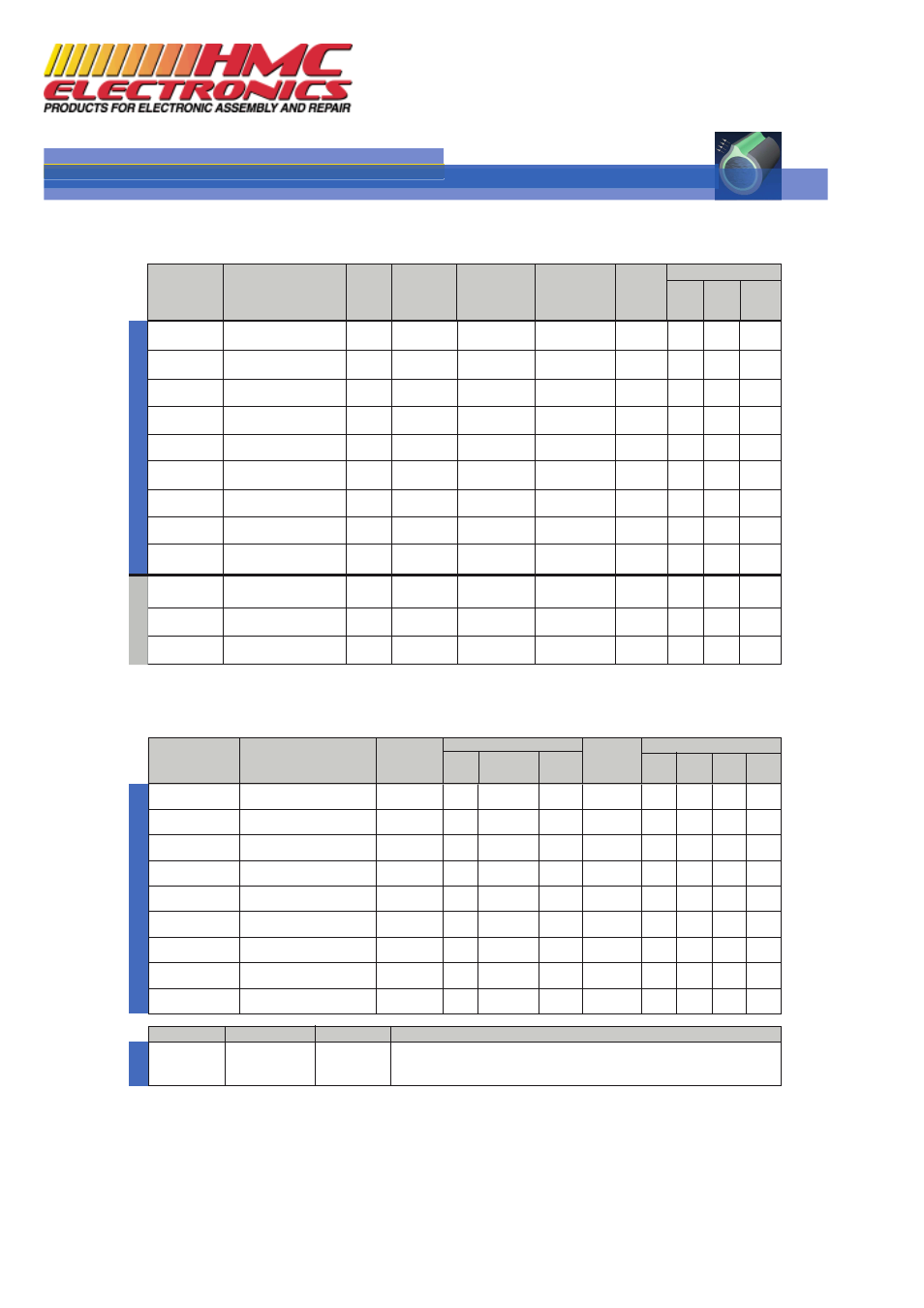

Product

(Color)

Key Features

Approximate

Viscosity

75°F (24°C)

(cps)

Time

(min)

Temperature

(°F/°C)

Pressure

(psi)

Average

T-Peel

at 75°F (24°C)

(piw)

-67°F

(-55°C)

75°F

(24°C)

180°F

(82°C)

250°F

(121°C)

Cure Conditions

Overlap Shear (psi)

3M

™

Scotch-Weld

™

One-Part Epoxy Adhesives and Metal Primers

Product (Color)

Description

Viscosity (cps)

Comments

3901

Adhesion promoter

5

A primer for film and liquid adhesives for improved metal and glass adhesion or improved resistance

(Red)

Organo-silane base

to environmental exposure with epoxy and urethane adhesives. Protects cleaned surfaces until bonding

Brush or spray

can be completed. Imparts improved corrosion protection to metal.

Primer

Epoxy

Note: The technical information and data on these pages should be considered representative or typical only and should not be used for specification purposes.

3M

™

Scotch-Weld

™

Two-Part Structural Adhesives

Epoxy

Note: The technical information and data on these pages should be considered representative or typical only and should not be used for specification purposes.

Product

(Color)

Key

Features

Mix Ratio

(Volume)

B:A

Approximate

Viscosity

75°F (24°C)

(cps)

Approximate

Mixed Worklife

at 75°F (24°C)

Approximate

Time to Handling

Strength at 75°F

(24°C)

Average

T-Peel at

75°F (24°C)

(piw)

Overlap Shear (psi)

-67°F

(-55°C)

75°F

(24°C)

180°F

(82°C)

3532 B/A

Multi-purpose

1:1

30,000

10 minutes

90 minutes

25

2,500

2,000

300

(Brown)

Semi-rigid bonds

3535 B/A

Multi-purpose

1:1

30,000

3 minutes

30 minutes

25

2,500

2,000

300

(Off-White)

Semi-rigid bonds

3549 B/A

Tough Flexible bonds

(Brown)

Non-sag

1:1

30,000

60 minutes

8 hours

25

2,500

2,000

300

Urethane

1838 B/A

Multi-purpose

4:5

400,000

60 minutes

8 hours

4

1,500

3,000

500

(Green)

Rigid bonds

1838 B/A

Multi-purpose

5:6

250,000

60 minutes

8 hours

4

1,500

2,000

500

(Tan)

Rigid bonds

1838L B/A

Multi-purpose

1:1

10,000

60 minutes

8 hours

4

2,000

2,500

300

(Translucent)

Rigid bonds

2158 B/A

Multi-purpose

1:1

375,000

2 hours

10 hours

3

1,500

2,000

400

(Gray)

Rigid bonds

2216 B/A

High performance

2:3

80,000

90 minutes

10 hours

25

3,000

3,200

400

(Gray)

Very flexible bonds

2216 B/A

General purpose

1:1

10,000

2 hours

14 hours

25

3,000

1,700

140

(Translucent)

Very flexible bonds

2216 B/A NS

High performance

2:3

350,000

2 hours

10 hours

25

2,000

2,500

400

(Tan)

Non-sag

3501 B/A

Multi-purpose

1:1

500,000

7 minutes

25 minutes

4

1,500

2,400

300

(Gray)

Rigid bonds

5

1751 B/A

Excellent void filler

3:2

700,000

45 minutes

10 hours

4

1,400

2,000

500

(Gray)

Rigid bonds

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

(800) 482-4440