HMC Electronics 43050 Loctite 430 SuperBonder, Instant Adhesive, Metal Bonder, Close Fitting Parts User Manual

Loctite

Technical Data Sheet

LOCTITE

®

430™

November

-

2010

PRODUCT DESCRIPTION

LOCTITE

®

430™

provides

the

following

product

characteristics:

Technology

Cyanoacrylate

Chemical Type

Methyl cyanoacrylate

Appearance (uncured)

Transparent, colorless liquid

LMS

Components

One part - requires no mixing

Viscosity

Low

Cure

Humidity

Application

Bonding

Key Substrates

Metals, Rubbers and Plastics

LOCTITE

®

430™ is a general purpose adhesive and is

particularly suited to bonding of metal substrates.

Commercial Item Description A-A-3097:

LOCTITE

®

430™ has been qualified to Commercial Item

Description A-A-3097. Note: This is a regional approval.

Please contact your local Technical Service Center for more

information and clarification.

TYPICAL PROPERTIES OF UNCURED MATERIAL

Specific Gravity @ 25 °C

1.1

Viscosity, Cone & Plate, mPa·s (cP):

Temperature: 25 °C, Shear Rate: 3,000 s

-1

60 to 90

Viscosity, Brookfield - LVF, 25 °C, mPa·s (cP):

Spindle 1, speed 30 rpm

70 to 110

LMS

Flash Point - See MSDS

TYPICAL CURING PERFORMANCE

Under normal conditions, the atmospheric moisture initiates the

curing process. Although full functional strength is developed

in a relatively short time, curing continues for at least 24 hours

before full chemical/solvent resistance is developed.

Cure Speed vs. Substrate

The rate of cure will depend on the substrate used. The table

below shows the fixture time achieved on different materials

at 22 °C / 50 % relative humidity. This is defined as the time to

develop a shear strength of 0.1 N/mm².

Fixture Time, seconds:

Steel (degreased)

20 to 40

Aluminum

30 to 60

Zinc dichromate

40 to 70

Neoprene

<10

Rubber, nitrile

<10

ABS

10 to 30

PVC

30 to 70

Polycarbonate

20 to 70

Phenolic

10 to 30

Cure Speed vs. Bond Gap

The rate of cure will depend on the bondline gap. Thin bond

lines result in high cure speeds, increasing the bond gap will

decrease the rate of cure.

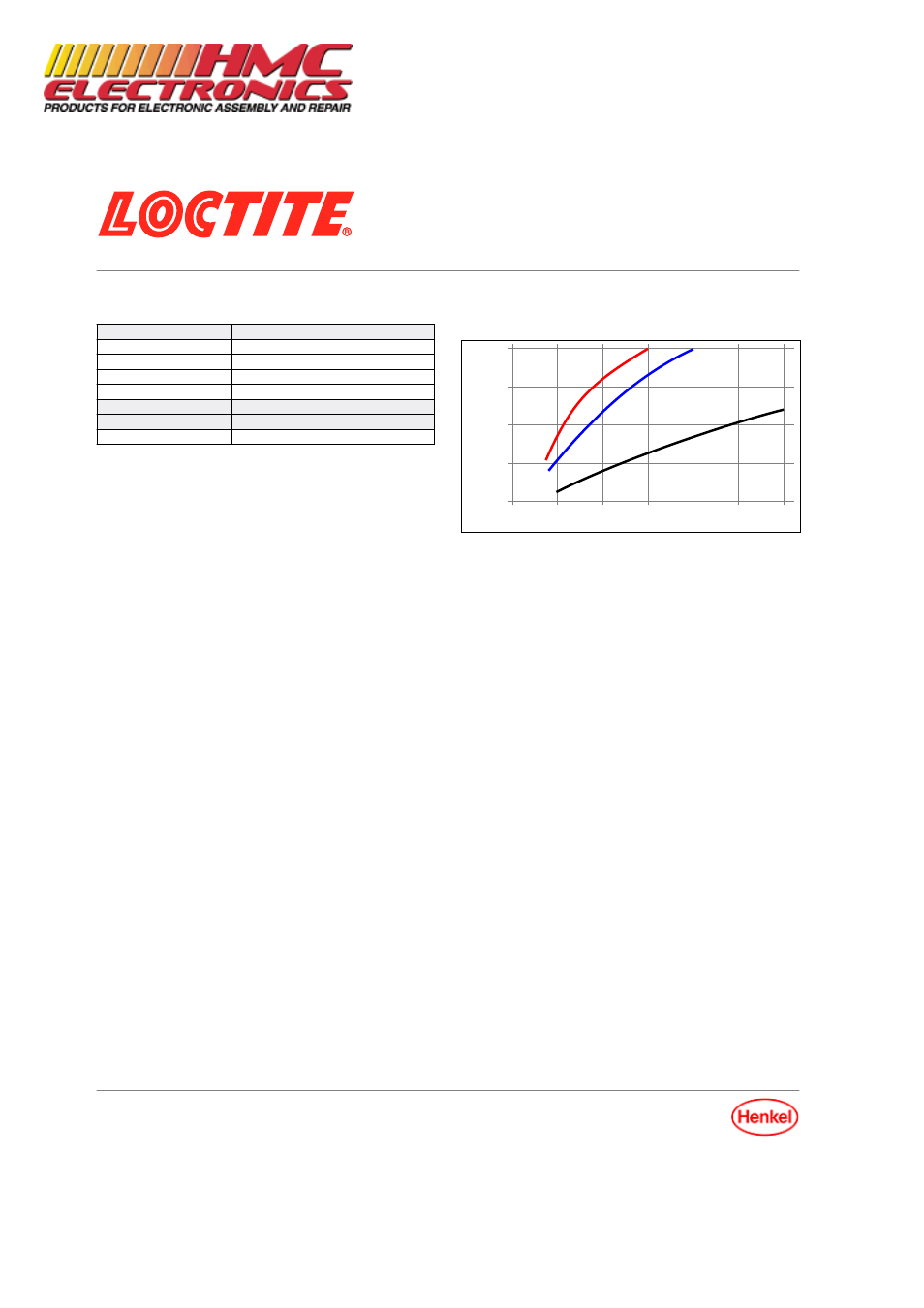

Cure Speed vs. Humidity

The rate of cure will depend on the ambient relative humidity.

The following graph shows the tensile strength developed with

time on Buna N rubber at different levels of humidity.

% Full Cured Strength @ 22 °C

Cure Time, seconds

100

75

50

25

0

0

10

20

30

40

50

60

60% RH

40% RH

20% RH

Cure Speed vs. Activator

Where cure speed is unacceptably long due to large gaps,

applying activator to the surface will improve cure speed.

However, this can reduce ultimate strength of the bond and

therefore testing is recommended to confirm effect.

TYPICAL PROPERTIES OF CURED MATERIAL

Cured for 24 hours @ 22 °C

Physical Properties:

Coefficient of Thermal Expansion,

ISO 11359-2, K

-1

100×10

-6

Coefficient of Thermal Conductivity, ISO 8302,

W/(m·K)

0.1

Glass Transition Temperature, ASTM E 228, °C 165

Electrical Properties:

Dielectric Constant / Dissipation Factor, IEC 60250:

0.1

-

kHz

2.65 / <0.02

1

-

kHz

2.75 / <0.02

10

-

kHz

2.75 / <0.02

Volume Resistivity, IEC 60093, Ω·cm

10×10

15

Surface Resistivity, IEC 60093, Ω

10×10

15

Dielectric Breakdown Strength,

IEC 60243-1, kV/mm

25

TYPICAL PERFORMANCE OF CURED MATERIAL

Adhesive Properties

Cured for 24 hours @ 22 °C

Lap Shear Strength, ISO 4587:

Steel (grit blasted)

N/mm² 20 to 30

(psi) (2,900 to 4,350)

Aluminum (grit blasted)

N/mm² 15 to 22

(psi) (2,175 to 3,190)

Zinc dichromate

N/mm² 4 to 12

(psi) (580 to 1,740)

ABS

N/mm² 6 to 20

(psi) (870 to 2,900)

PVC

N/mm² 6 to 20

(psi) (870 to 2,900)

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

(800) 482-4440