HMC Electronics 32430 Loctite 324 Speedbonder, High Impact Adhesive User Manual

Loctite

Technical Data Sheet

LOCTITE

®

324™

February

-

2005

PRODUCT DESCRIPTION

LOCTITE

®

324™

provides

the

following

product

characteristics:

Technology

Acrylic

Chemical Type

Urethane methacrylate ester

Appearance (uncured)

Transparent light amber liquid

LMS

Components

One component - requires no mixing

Viscosity

Medium

Cure

Anaerobic with activator

Cure Benefit

Room temperature cure

Application

Bonding

LOCTITE

®

324™ is used to bond flat parts together. Especially

suitable for joining dissimilar materials, e.g. ferrite to plated

materials in electric motors, loudspeakers, etc. This product is

specifically formulated for toughness and impact strength.

LOCTITE

®

324™ cures when confined between close fitting

parts with the aid of an activator.

TYPICAL PROPERTIES OF UNCURED MATERIAL

Specific Gravity @ 25 °C

1.06

Flash Point - See MSDS

Viscosity, Brookfield - RVT, 25 °C, mPa·s (cP):

Spindle 6, speed 20 rpm

10,000 to 24,000

LMS

TYPICAL CURING PERFORMANCE

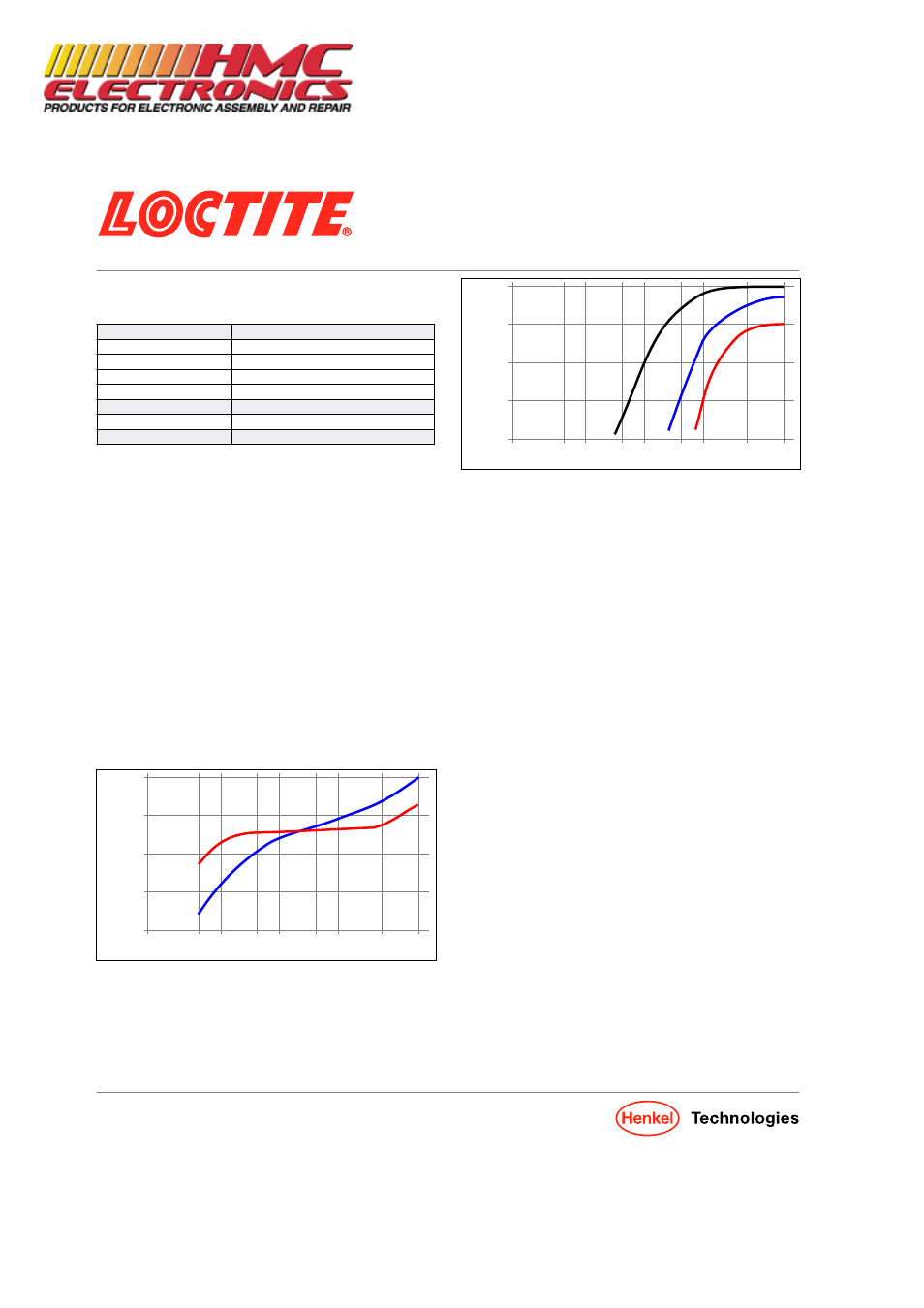

Cure Speed vs. Substrate

The rate of cure will depend on the substrate used. The graph

below shows the shear strength developed with time on grit

blasted steel lap shears compared to different materials and

tested according to ISO 4587. (Activator 7075™ applied to

one surface)

% of Full Strength on Steel

Cure Time

100

75

50

25

0

1min

5min10min 30min 1h

3h 6h

24h

72h

Steel

Aluminum

Cure Speed vs. Bond Gap

The rate of cure will depend on the bondline gap. The following

graph shows the shear strength developed with time on grit

blasted steel lap shears at different controlled gaps and tested

according to ISO 4587. (Activator 7075™ applied to one

surface)

% of Full Strength on Steel

Cure Time

100

75

50

25

0

1min

5min10min 30min 1h

3h 6h

24h

72h

0.25mm

0.5mm

0.05mm

TYPICAL PROPERTIES OF CURED MATERIAL

Physical Properties:

Coefficient of Thermal Expansion, ASTM D 696, K

-1

80×10

-6

Coefficient of Thermal Conductivity, ASTM C 177,

W/(m·K)

0.1

Specific Heat, kJ/(kg·K)

0.3

Elongation, at break, ISO 37, %

170

Tensile Strength, ISO 37

N/mm² 34

(psi) (4,900)

Tensile Modulus, ASTM D 638

N/mm² 614

(psi) (89,000)

Electrical Properties:

Dielectric Constant / Dissipation Factor, IEC 60250:

100

-

Hz

5.5 / 0.033

1

-

kHz

5.2 / 0.031

1

-

MHz

4.5 / 0.004

Volume Resistivity, IEC 60093, Ω·cm

8×10

12

Surface Resistivity, IEC 60093, Ω

2×10

17

Dielectric Breakdown Strength, IEC 60243-1, kV/mm

73

TYPICAL PERFORMANCE OF CURED MATERIAL

Adhesive Properties

After 24 hours @ 22 °C, Activator 7075™ on 1 side

Lap Shear Strength, ISO 4587:

Steel (grit blasted):

0 gap

N/mm² 17 to 21

(psi) (2,500 to 3,000)

0.5 mm gap

N/mm² 21 to 25

(psi) (3,000 to 3,600)

"T" Peel Strength, ISO 11339:

Steel (grit blasted)

N/mm 2.2

(lb/in) (13)

After 24 hours @ 22 °C, Activator 7075™ on 2 sides

Lap Shear Strength, ISO 4587:

Steel (grit blasted):

0.5 mm gap

N/mm² ≥14

LMS

(psi) (≥2,030)

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

(800) 482-4440