HMC Electronics 101-1 Permabond 101 Cyanoacrylate Adhesive, General Purpose, Wicking Type, Plastic Bonding User Manual

Permabond 101 cyanoacrylate, Features & benefits, Description

The information given and the recommendations made herein are based on our research and are believed to be accurate but no guarantee of their accuracy is made. In every case

we urge and recommend that purchasers before using any product in full-scale production make their own tests to determine to their own satisfaction whether the product is of

acceptable quality and is suitable for their particular purpose under their own operating conditions. THE PRODUCTS DISCLOSED HEREIN ARE SOLD WITHOUT ANY WARRANTY

AS TO MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY OTHER WARRANTY, EXPRESS OR IMPLIED.

No representative of ours has any authority to waive or change the foregoing provisions but, subject to such provisions, our engineers are available to assist purchasers in adapting our products

to their needs and to the circumstances prevailing in their business. Nothing contained herein shall be construed to imply the non-existence of any relevant patents or to constitute a permission,

inducement or recommendation to practice any invention covered by any patent, without authority from the owner of this patent. We also expect purchasers to use our products in

accordance with the guiding principles of the Chemical Manufacturers Association’s Responsible Care® program.

Global TDS Revision 1

Page

1/2

Features & Benefits

Ultra‐low viscosity

Suitable for bonding pre‐assembled parts

Ideal for close‐fitting plastic components

Description

PERMABOND 101

is a low viscosity product useful in

wicking or penetrating applications or bonding

closely fitting parts. It is fast setting and suitable for

use on plastics, rubber and metals.

Cyanoacrylate adhesives are single component

adhesives that polymerize rapidly when pressed into

a thin film between parts. The moisture adsorbed on

the surface initiates the curing of the adhesive.

Strong bonds are developed extremely fast and on a

great variety of materials. These properties make

PERMABOND cyanoacrylates the ideal adhesives for

high speed production lines.

Physical Properties of Uncured Adhesive

Chemical composition

Ethyl cyanoacrylate

Appearance

Colourless

Viscosity @ 25°C

1‐3 mPa.s

(cP)

Density

1.05

Typical Curing Properties

Maximum gap fill

0.05 mm

0.002 in

Fixture / handling time*

3‐5 seconds (Steel)

2‐5 seconds (Buna N Rubber)

5‐10 seconds (Phenolic)

Full strength

24 hours

*Handling times can be affected by temperature, humidity and

specific surfaces being bonded. Larger gaps or acidic surfaces will

also reduce cure speed but this can be overcome by the use of

Permabond C Surface Activator (CSA) or Permabond QFS 16.

Typical Performance of Cured Adhesive

Shear strength*

ASTM D‐1002

Steel 19‐23 N/mm²

(2800‐3300 psi)

Aluminium 7‐9 N/mm²

(1000‐1300 psi)

Zinc 8‐10 N/mm²

(1200‐1500 psi)

ABS >6 N/mm²

(900psi)

SF

PVC >6 N/mm²

(900psi)

SF

PC >5 N/mm²

(700 psi)

SF

Phenolic 12‐14N/mm²

(1700‐

2000 psi)

Impact Strength

(ASTM D‐950)

6‐14 kJ/m²

(3‐7 ft‐lb/in²)

Shore A hardness

85

Coefficient of

thermal expansion

90 x 10

‐6

mm/mm/°C

Dielectric strength

10 mV/mm

Thermal

conductivity

0.1 W/(m.K)

*Strength results will vary depending on the level of surface

preparation and gap.

SF = Substrate failure

Temperature Resistance

0

20

40

60

80

100

120

‐50

0

50

100

150

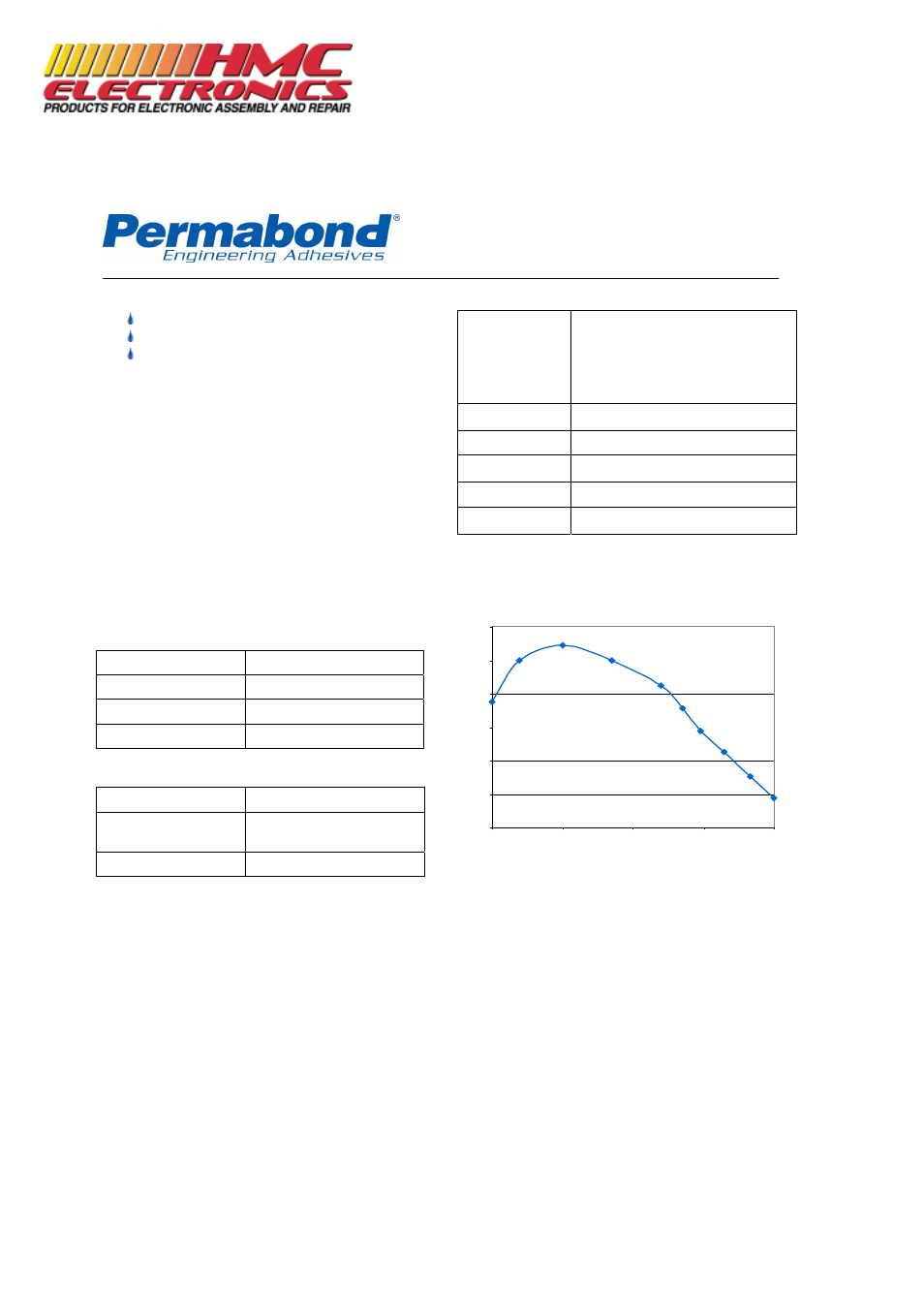

“Hot strength” shear strength tests performed on mild steel. 24hr cure at

room temperature and conditioned to pull temperature for 30 minutes

before testing.

101 can withstand higher temperatures for brief periods

(such as for paint baking and wave soldering processes)

providing the joint is not unduly stressed. The minimum

temperature the cured adhesive can be exposed to is

‐55°C (‐65°F) depending on the materials being bonded.

%

Strength

retention

Temperature °C

PERMABOND 101

Cyanoacrylate

Technical Datasheet

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

(800) 482-4440