HMC Electronics 29021 Loctite 290 Threadlocker Adhesive, Penetrating, Wicking Grade User Manual

Loctite

Technical Data Sheet

LOCTITE

®

290™

January

-

2010

PRODUCT DESCRIPTION

LOCTITE

®

290™

provides

the

following

product

characteristics:

Technology

Acrylic

Chemical Type

Dimethacrylate ester

Appearance (uncured)

Green liquid

LMS

Fluorescence

Positive under UV light

LMS

Components

One component - requires no mixing

Viscosity

Low

Cure

Anaerobic

Secondary Cure

Activator

Application

Threadlocking

Strength

Medium to High

LOCTITE

®

290™ is designed for the locking and sealing of

threaded fasteners. Because of its low viscosity and capillary

action, the product wicks between engaged threads and

eliminates the need to disassemble prior to application. The

product cures when confined in the absence of air between

close fitting metal surfaces and prevents loosening and

leakage from shock and vibration. The product can also fill

porosity in welds, castings and powdered metal parts.

Mil-S-46163A

LOCTITE

®

290™ is tested to the lot requirements of Military

Specification Mil-S-46163A. Note: This is a regional approval.

Please contact your local Technical Service Center for more

information and clarification.

ASTM D5363

Each lot of adhesive produced in North America is tested to

the general requirements defined in paragraphs 5.1.1 and

5.1.2 and to the Detail Requirements defined in section 5.2.

NSF International

Registered to NSF Category P1 for use as a sealant where

there is no possibilty of food contact in and around food

processing areas. Note: This is a regional approval. Please

contact your local Technical Service Center for more

information and clarification.

NSF International

Certified to ANSI/NSF Standard 61 for use in commercial and

residential potable water systems not exceeding 82° C. Note:

This is a regional approval. Please contact your local Technical

Service Center for more information and clarification.

TYPICAL PROPERTIES OF UNCURED MATERIAL

Specific Gravity @ 25 °C

1.08

Flash Point - See MSDS

Viscosity, Brookfield - RVT, 25 °C, mPa·s (cP):

Spindle 1, speed 50 rpm

20 to 55

LMS

TYPICAL CURING PERFORMANCE

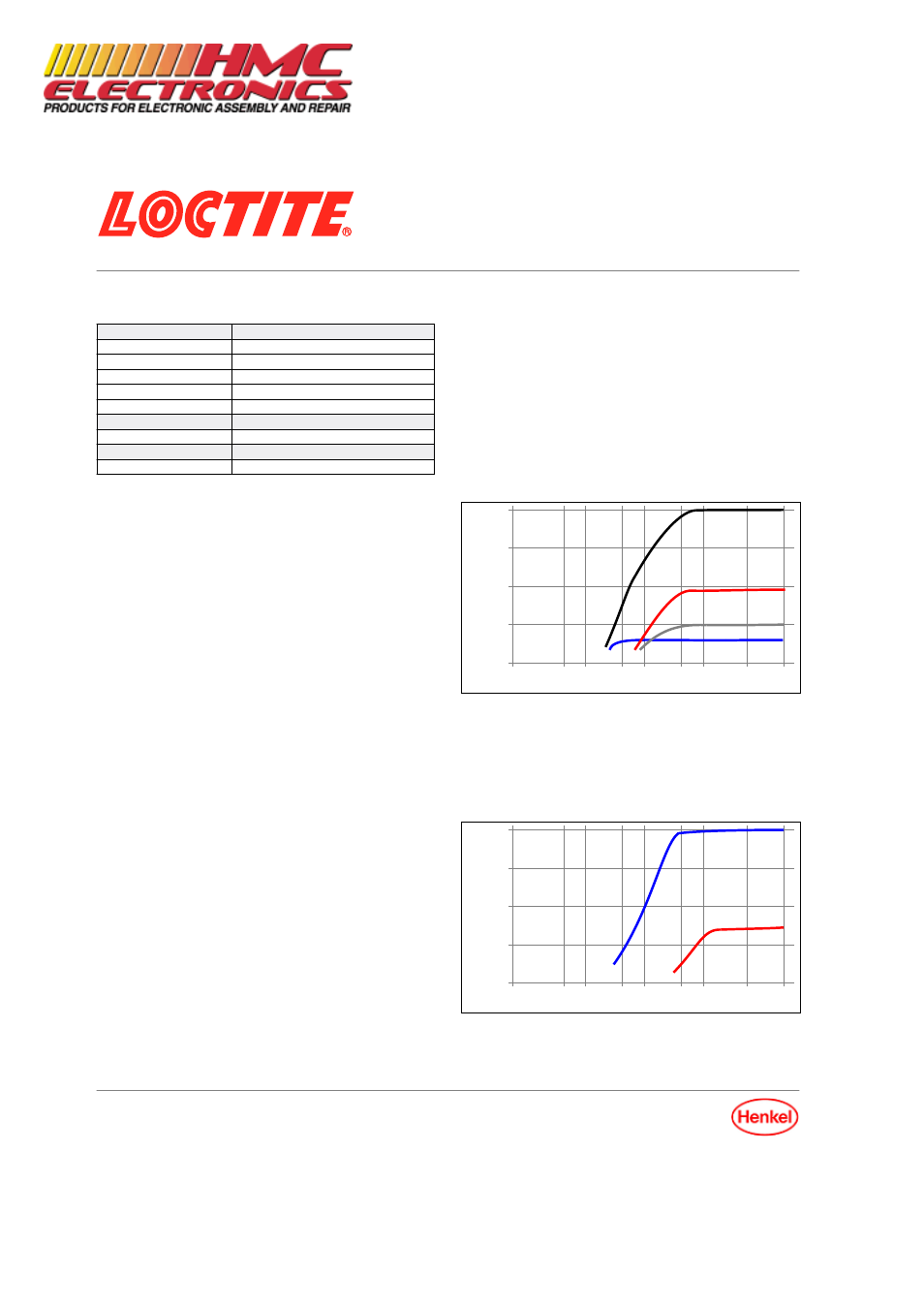

Cure Speed vs. Substrate

The rate of cure will depend on the substrate used. The graph

below shows the breakaway strength developed with time on

M10 steel nuts and bolts compared to different materials and

tested according to ISO 10964.

% of Full Strength on Steel

Cure Time

100

75

50

25

0

1min

5min10min 30min 1h

3h 6h

24h

72h

Steel

Brass

Zinc dichromate

Stainless steel

Cure Speed vs. Bond Gap

The rate of cure will depend on the bondline gap. Gaps in

threaded fasteners depends on thread type, quality and size.

The following graph shows shear strength developed with time

on steel pins and collars at different controlled gaps and tested

according to ISO 10123.

% of Full Strength on Steel

Cure Time

100

75

50

25

0

1min

5min10min 30min 1h

3h 6h

24h

72h

0.05 mm

0.15 mm

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

(800) 482-4440