Scotch-weld, Structural adhesives coverage guide, Surface preparation tips – HMC Electronics DP100 3M DP-100 Scotch-Weld Epoxy Adhesive User Manual

Page 10

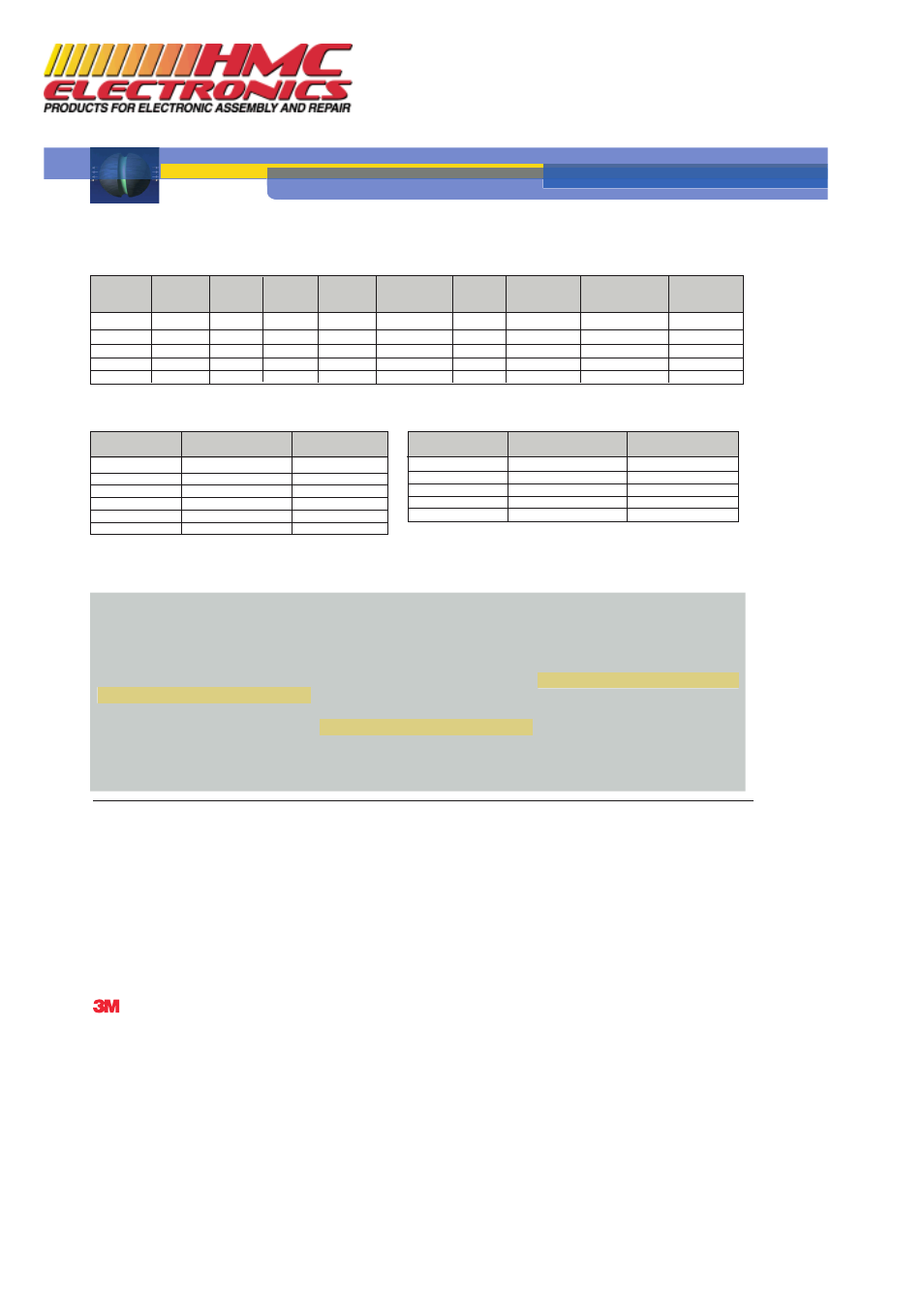

Wet Thickness

Square Ft per gal.

Approx. gal.reqd.

per 1000 Square Ft.

(approx.)

per 1000 Square Ft.

1/2 in.

3.2

312.0

1/8 in.

12.8

78.0

1/16 in.

25.6

39.0

1/32 in.

51.2

20.0

25 mils

64.0

16.0

1 mil

1600.0

0.62

Bead Size

Approx. Lineal

Approx. gal. per

Dimension*

Ft. per gal.

1000 Lineal Ft.

1/2 in.

196

5.0

3/8 in.

350

3.0

1/4 in.

785

1.3

1/8 in.

3,130

0.32

1/16 in.

12,420

0.08

Bead Size

Linear Ft. Linear Ft.

Linear Ft.

Linear Ft.

Linear Ft.

Linear Ft.

Linear Ft.

Linear Ft.

Linear Ft.

Dimension*

per 35 ml

per 37 ml

per 43 ml

per 50 ml

per 200 ml

per 250 ml

per 250 ml

per 12 fl. oz. (355 ml)

per 400 ml

(10:1 Cart.)

(2:1 Cart.)

(3:2 Cart.)

(1:1 Cart.)

(1:1 & 2:1 Cart.) (10:1 Cart.) (1:1 Caulk Cart.)

(1:1 & 2:1 Cart.)

(1:1 & 2:1 Cart.)

1/2 in.

1.9

2.0

2.2

2.5

10

12.5

12.5

19

21

3/8 in.

3.3

3.5

3.9

4.5

18

22.5

22.5

33

37

1/4 in.

7.5

8.0

9.0

10.5

41

52

52

75

83

1/8 in.

29.3

31.0

35.7

41.5

165

205

205

298

331

1/16 in.

115.2

122.0

142.0

165.0

656

825

825

1182

1313

Approximate Coverages for 3M

™

Scotch-Weld

™

Adhesives in Duo-Pak Cartridges

Coverages per Gallon for Various Thicknesses of

100% Solids 3M Adhesives

Coverages per Gallon for Various

Bead Sizes of 100% Solids 3M Adhesives

* Bead size is semi-circular bead with width equal to size noted and

height at center of bead equal to 1/2 the width.

NOTE: The technical information and data provided here should be considered representative or typical only and should not be used for specification purposes.

3M

™

Scotch-Weld

™

Structural Adhesives Coverage Guide

Industrial Adhesives and Tapes Division

3M Center Bldg. 21-1W-10

900 Bush Ave.

St. Paul, MN 55144

1-800-362-3550

www.3M.com/adhesives

Printed in U.S.A.

© 2008 3M

78-9236-7114-9

PRODUCT USE: All statements, technical information and recommendations contained in this document are based upon tests or experience that 3M believes

are reliable. However, many factors beyond 3M’s control can affect the use and performance of a 3M product in a particular application, including the

conditions under which the product is used and the time and environmental conditions in which the product is expected to perform. Since these factors

are uniquely within the user’s knowledge and control, it is essential that the user evaluate the 3M product to determine whether it is fit for a particular

purpose and suitable for the user’s method of application. WARRANTY AND LIMITED REMEDY: 3M warrants that each 3M product meets the

applicable specifications at the time 3M ships the product. 3M MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT

LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY IMPLIED WARRANTY ARISING

OUT OF A COURSE OF DEALING, CUSTOM OR USAGE OF TRADE. User is responsible for determining whether the 3M product is fit for a particular

purpose and suitable for user’s application. If the 3M product is defective, your exclusive remedy and 3M’s and seller’s sole obligation will be, at 3M’s

option, to repair or replace the product or refund the purchase price. LIMITATION OF LIABILITY: Except where prohibited by law, 3M and seller will

not be liable for any loss or damage arising from the 3M product, whether direct, indirect, special, incidental or consequential, regardless of the legal

theory asserted, including warranty, contract, negligence or strict liability.

3M, Scotch-Weld

and Scotch-Brite are

trademarks of 3M Company.

Surface Preparation Tips

The following surface preparation steps

are generally recommended for most

substrates and structural adhesives:

Metals

1. Wipe surface with isopropyl alcohol

(IPA) or methyl ethyl ketone (MEK)

using a clean cloth. A heavier degreaser

may be needed if the substrate contains

a layer of processing oil.

2. Lightly abrade surface with sandblasting,

fine grit sandpaper, or 3M

™

Scotch-Brite

™

7447 maroon pads.

3. Wipe surface with IPA or MEK to

remove debris.

4. Allow solvent to evaporate before

applying adhesive.

Plastics and Rubbers

1. Lightly abrade surface with sandblasting,

fine grit sandpaper, or 3M

™

Scotch-Brite

™

7447 maroon pads.

2. Wipe surface with IPA using a clean

cloth to remove debris.

3. Allow solvent to evaporate before

applying adhesive.

Glass

1. Wipe surface using a clean cloth with

acetone or MEK containing 0.5 wt%

silane adhesion promoter.

2. Allow solvent to evaporate before

applying adhesive.

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

(800) 482-4440