Festo DSL-16 … 40-270-…-B User Manual

Page 4

9.Press the protective cap of the DSL back onto the snap

ring of the housing (if present).

The protective cap can also be snapped onto freely

positioned shock absorber retainers if the elements

are broken through at the predetermined breaking

point. Observe the fitting instructions for the cover cap.

When all stops have been adjusted:

• Check whether additional shock absorbers or stops are

necessary.

Additional shock absorbers or stops are necessary in

the following cases:

– for movable masses with a calculated mass moment

of inertia greater than the

permitted mass moment of

inertia

– when the DSL is operated without an air cushion on

the exhaust side (e.g. after long breaks between

the individual swivel movements).

Shock absorber retainers for internal fitting of shock

absorbers/elastomer absorbers can be ordered

separately and installed on the DSL (

Accessories).

4.3 Fitting pneumatic components

• Use GRLA one-way flow control valves for setting the

swivel speed and stroke speed.

These are screwed directly into the compressed air

ports.

With eccentric masses:

• Check whether HGL controlled non-return valves or a

VZS compressed air reservoir are necessary.

In this way you can prevent the moveable mass from

sliding down suddenly if there is a sudden drop in pres-

sure.

4.4 Fitting electric components

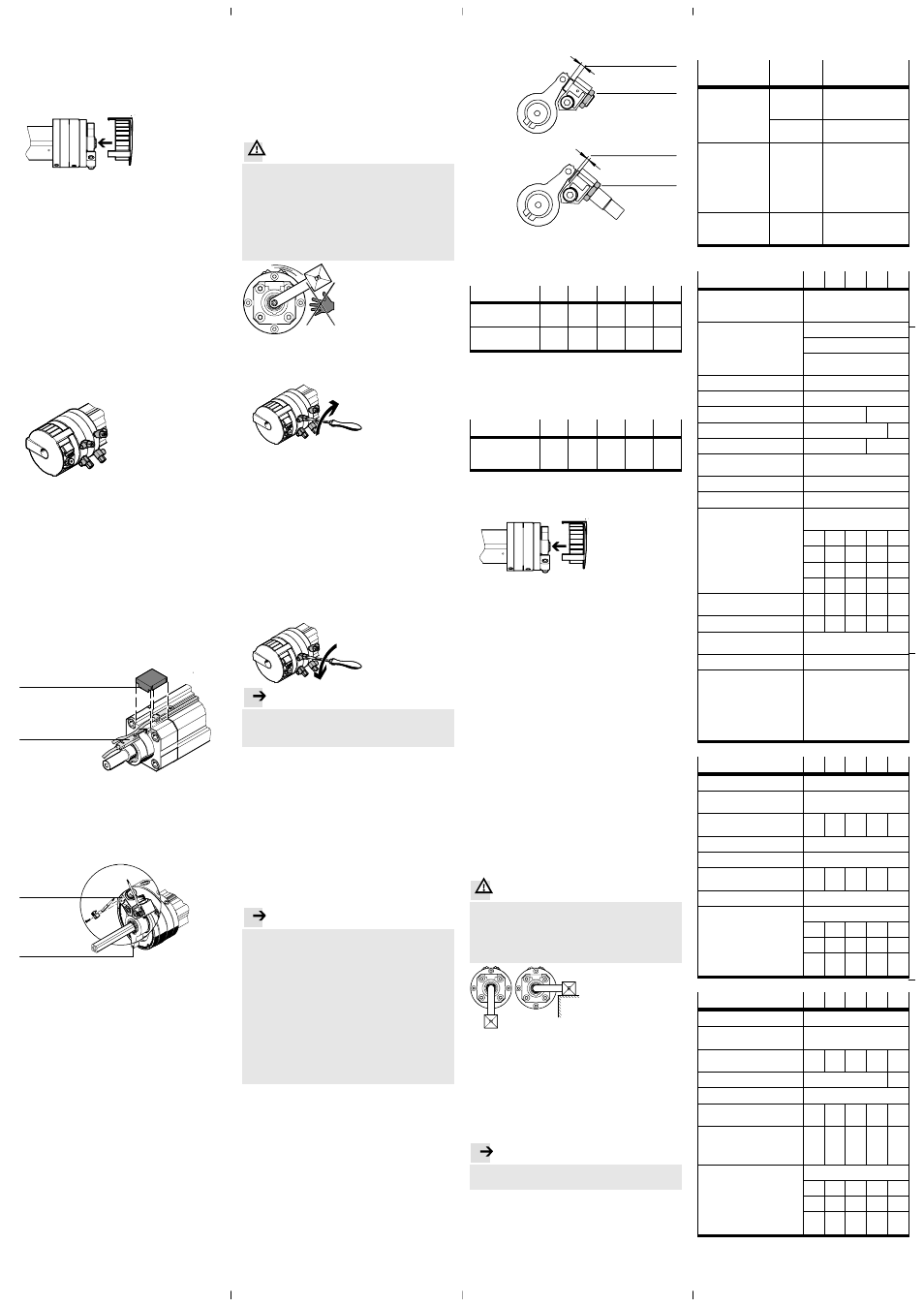

For sensing the cylinder end positions:

• Place the proximity switches

aF in the double groove of

the profile.

1.Lift up the cover cap

2 with a flat screwdriver.

2.Push a proximity switch

aF for each of the end posi-

tions into a groove.

3.Press the cover cap tight again.

aF

2

For sensing the swivel end positions:

• Place the proximity switches on the guide rim

aG of the

absorber retainers.

Sensor supports (

Accessories) are required for

fastening the proximity switches.

The proximity switch is actuated by the magnet

aH in

the stop lever.

aG

aH

5 Commissioning

5.1 Commissioning the complete system

• Pressurise your entire system slowly.

This will prevent uncontrolled movements from

occurring.

5.2 Commissioning an individual unit

Warning

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Risk of injury from rotating masses.

• Make sure that the DSL is set into motion only when

the safeguards are fitted.

• Make sure that:

– nobody can reach into the swivel/positioning

range of the DSL

– no objects lie in the positioning path (e.g. by

providing an individual protective screen).

1.Tighten the two upstream one-way flow control valves

– first close completely

– then loosen approximately one turn.

2.Make sure that the operating conditions lie within the

permitted ranges.

3.Pressurise the drive in one of the following ways:

–

slow pressurisation of one side of the swivel or linear

component

– simultaneous pressurisation of both sides with

subsequent exhausting of one side.

4.Start a test run.

5.During the test run check whether the following

settings on the DSL need to be modified:

– the swivel range of the moveable mass

– the swivel speed of the moveable mass.

6.Unscrew the one-way flow control valves slowly until

the desired swivel speed is set. The stop lever

6

should reach the end position, but not strike hard

against it.

Note

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

If the impact is too hard, it will cause the stop lever to

rebound out of the end position, resulting in a reduc-

tion of the service life.

If the stop lever can be heard to strike hard:

7.Interrupt the test run.

Causes of hard knocking may be:

– Mass moment of inertia of the moveable mass too

high.

– Swivel speed of the moveable mass too high.

– No compressed air cushion on the exhaust side.

– Insufficient shock absorption.

8.Make sure you remedy the above-mentioned causes.

9.Repeat the test run.

When all necessary corrections have been undertaken:

10. Conclude the test run.

5.3 Fine adjustment of the end positions

Note

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A shock absorber that is screwed too far in or out

results in the stop lever:

– either hitting the shock absorber retainer without

shock absorption

or

– hitting the shock absorber at an impermissible angle.

In such a case there is a risk of the DSL or the shock

absorber being damaged.

• Make sure that you do not screw the shock absorber

in or out any further than shown in the following ta-

ble.

Otherwise the shock-absorbing performance of the

shock absorber/elastomer absorber will be insuffi-

cient or even completely ineffective.

• Pressurise the desired end position on the DSL.

The end positions can be adjusted under pressure.

1.Remove the protective cap from the housing

(if present).

2.Unscrew the locking nut

bJ of the shock absorber.

The unscrewing length of the shock absorber (Elas-

tomer absorber

aI or shock absorber bA) can be used

to compensate the deviation of the end position.

This occurs during pre-adjustment when the shock ab-

sorber is moved against the unpressurised stop lever.

bJ

aI

DSL-...-P

DSL-...-CC

bA

bJ

3.Screw the shock absorber into or out of the shock ab-

sorber retainer using a hexagon spanner.

The permissible unscrewing lengths are summarised in

the following table.

DSL-…-270-...-B

16

20

25

32

40

Unscrewing

length

aI

[mm] 0 … 2.5

0 … 3

0 … 4

0 … 4.5

0 … 5.4

Screwing-in

length

bA

[mm] 0 … 1.25 0 … 1.5

0 … 2

0 … 2.25 0 … 2.7

When all stops have been adjusted:

4.Tighten the locking nuts

bJ of the shock absorbers

again.

The necessary tightening torques are summarized in

the following table.

DSL-…-270-...-B

16

20

25

32

40

Tightening

torque of the

locking nut

bJ

[Nm] 2

3

3

5

20

5.Check that the proximity switches function correctly.

6.Press the protective cap of the DSL back onto the snap

ring (if present).

7.Repeat the test run.

6 Operation

With several uninterrupted swivel cycles:

• Make sure that the maximum permitted swivel

frequency is not exceeded (

Technical specifications).

Otherwise, functional reliability will be impaired by

excessive heating.

To extend the service life of the shock absorbers:

• Apply a thin coating of grease to the stop caps of the

shock absorbers.

Checking for proper functioning:

• Check the shock absorbers for oil loss after every 2 mil-

lion switching cycles.

• Change shock absorbers with visible oil loss or at the

latest every 5 million switching cycles (

Accessories).

7 Care and maintenance

If the device is dirty:

• Clean the DSL with a soft cloth.

All non-abrasive cleaning agents are permitted

(e.g. warm soap suds up to +60 °C).

8 Dismantling and repairs

With eccentric masses on the lever arm:

Warning

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Risk of injury from masses that slide down suddenly if

there is a drop in pressure.

• Make sure that the mass has reached a stable posi-

tion before the DSL is exhausted (e.g. the lowest

point).

Recommendation:

• Return the product to our Repair Service.

The necessary accurate adjustments and tests will then

be taken into account.

• Information on spare parts and aids can be found

under: www.festo.com/spareparts.

9 Accessories

Note

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

• Please select the appropriate accessories from our

catalogue www.festo.com/catalogue.

10 Eliminating faults

Fault

Possible

cause

Remedy

Uneven movement of

the moveable mass

Flow control

valves inserted

incorrectly

Check the flow control

valve function (exhaust air

flow control)

Asymmetric

angle setting

Symmetric setting

preferred

– Hard impact at the

end position

– Piston rod does

not remain in the

end position

Residual energy

too high

– Select smaller stroke or

swivel speed

– Use external shock

absorbers

– Move only against

residual air cushion

on the exhaust side

– Select a lighter mass

Piston rod moves only

with great difficulty or

not at all

Bending stress

via the drive

rod

Avoid bending stress

(especially on the

square

aB)

11 Technical specifications

DSL-…-270-...-B

16

20

25

32

40

Constructional design

Combined stroke/rotary cylinder

with swivel vane – in each case

double-acting

End position cushioning

– Linear motion

P – not adjustable at either end

– Swivel component

None (may only be operated with

shock absorption)

Mounting position

as desired

Min. stroke length

[mm] 10

Max. stroke length

DSL

[mm] 160

200

Max. stroke length

DSL-KF

[mm] 100

160

Pneumatic connection

M5

G

Á

Operating medium

Filtered compressed air,

lubricated or unlubricated

Operating pressure

[bar]

2.5 … 8

Ambient temperature

[°C]

–10 … +60

Theoretical effective

power F

X

at 6 bar

– advancing

DSL

[N]

102.5 159

246

422.5 660

– retracting

DSL

[N]

73.5

120.5 173.5 294

495

– advancing

DSL-KF

[N]

103.5 158

248

403.5 603

– retracting

DSL-KF

[N]

73.5

120.5 173.5 294

495

Permitted dynamic

load torque

DSL-KF

[Nm]

0.17

0.35

0.7

1.0

5.4

Torque at 6 bar

[Nm]

1.25

2.5

5

10

20

Max. piston speed of

linear component

[mm/s] 500

Note on materials

free of copper and PTFE

Materials:

– housing, flange stop lever,

cover

– piston rod / shaft

– swivel vane, cap

– stop screw,

stops, screws

– seals

anodised aluminium

steel, nickel-plated

fibreglass-reinforced plastic

stainless steel

galvanised steel

polyurethane

DSL-…-270-P-...-B

16

20

25

32

40

End position cushioning

Elastomer shock absorbers

End position adjustment

via elastomer shock absorbers

with fixed stop

Max. permissible mass

moment of inertia

[10

-4

kg m

2

]

0.35

0.7

1.1

1.7

2.4

Swivel angle

[°]

270

Swivel angle adjustment

[°]

-6

Shock absorbing angle,

single

[°]

1.8

1.4

1.2

1.4

2

Swivel frequency

[Hz]

2

Weight

[kg]

– Basic weight

DSL

0.70

1.09

1.61

2.99

5.30

– Basic weight

DSL-KF

0.75

1.18

1.66

3.02

5.21

– Linear component per 10 mm

stroke

0.033 0.052 0.067 0.109 0.175

DSL-…-270-CC-...-B

16

20

25

32

40

End position cushioning

Shock absorbers

End position adjustment

via shock absorbers with fixed

stop

Max. permissible mass

moment of inertia

[10

-4

kg m

2

]

7

12

16

21

40

Swivel angle

[°]

246

240

Swivel angle adjustment

[°]

-3

Shock absorbing angle,

single

[°]

15

12

10

12

16

Swivel frequency with

2 shock absorbers

– at max. swivel angle

– at smaller swivel angles

1.5

2

1

1.5

1

1.5

0.7

1.5

0.7

1.5

Weight

[kg]

– Basic weight

DSL

0.7

1.13

1.61

3.02

5.21

– Basic weight

DSL-KF

0.75

1.22

1.75

3.30

5.36

– Linear component per 10 mm

stroke

0.033 0.052 0.067 0.109 0.175