Festo DSL-16 … 40-270-…-B User Manual

Page 3

Note

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

en Fitting and commissioning to be carried out only

by qualified personnel in accordance with the

operating instructions.

Note the warnings and instructions on the product

and in the relevant operating instructions.

The specifications/instructions in the relevant

documentation supplied with the product must be

observed.

First read through all the operating instructions

supplied with the product. In this way you can

avoid extra expense due to any necessary correc-

tive measures.

1

3

4

6 7

8

9

aE

aA aJ

aB

5

aC

2

aD

1

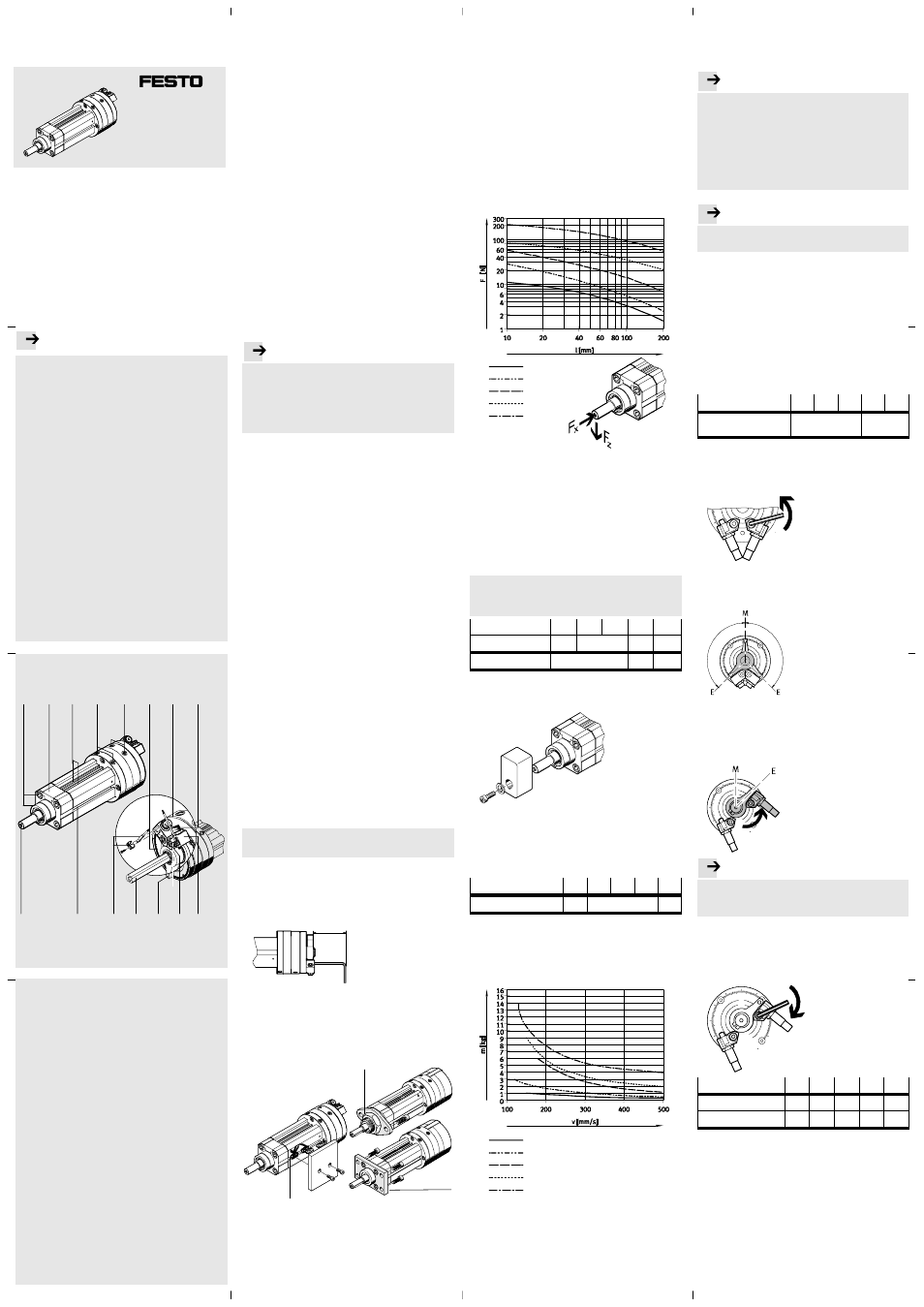

Thread for fastening

2

Cover cap

3

Double groove for proximity switch

4

Compressed air connections for linear

component

5

Compressed air supply ports for swivel

component

6

Angle scale

7

Snap ring for protective cap

8

Shock absorber with locking nut (optional)

9

Shock absorber retainer (optional)

aJ

Locking screw for absorber retainer

aA

Stop lever with integrated magnet for

position monitoring

aB

Square (projecting length depending on

position of linear component)

aC

Sensor support with proximity switch

(optional)

aD

Groove for fastening with slot nuts

aE

Extendable piston rod with thread and

feather key

Fig. 1

Swivel/linear unit

en

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type DSL-16 … 40-270-…-B

1 Function and application

The combination of swivel component and linear compo-

nent in one product permits overlapping movements.

When the compressed air ports are pressurised alter-

nately, the inner vane in the housing swivels backwards

and forwards. This swivel movement is transmitted to

the outer stop lever and converted to a rotary movement

on the piston rod. The angle of rotation can be limited

for the stop lever by means of adjustable shock ab-

sorber elements (elastomer absorbers or shock ab-

sorbers).

Irrespective of this, the piston rod extends or retracts

when the relevant compressed air ports are pressurised

alternately.

The DSL swivel-linear module has been designed for the

combined movement of work loads which do not have to

carry out a complete revolution.

2 Transport and storage

• Take into account the weight of the DSL:

It weighs up to 7 kg.

• Ensure storage conditions as follows:

– Storage times should be kept to a minimum

– cool, dry, shaded storage locations protected from

corrosion.

3 Conditions of use

Note

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Malfunctions will occur if the device is not used

correctly.

• Ensure that the specifications in this chapter are

always observed.

• Note the warnings and instructions on the product

and in the relevant operating instructions.

• Compare the maximum values specified in these

operating instructions with your actual application

(e.g. pressures, forces, torques, temperatures,

masses).

The product can only be operated in accordance with

the relevant safety guidelines if the maximum loading

limits are observed.

• Take into consideration the ambient conditions at the

location of use.

Corrosive elements in the environment (e.g. ozone) will

reduce the service life of the product.

• Ensure that all applicable safety regulations are ob-

served, e.g. from trade associations or national auth-

orities.

• Remove the packaging.

It is intended that the packaging be recycled on the

basis of its constituent materials (exception: oiled

paper = other waste).

• Ensure that the compressed air is properly prepared

(

Technical specifications).

• Use the same medium composition throughout the

service life of the product. Example:

If unlubricated compressed air is selected at the outset,

then unlubricated compressed air should be used dur-

ing the complete service life of the product.

• Pressurise your complete system slowly until the oper-

ating pressure is reached. This ensures that all actuator

movement is controlled.

For slow start-up pressurisation use safety start-up

valve type HEL.

• Use the product in its original state. Unauthorised

modification is not permitted.

4 Fitting

4.1 Fitting mechanical components

Definition

moving mass = work load (+ mass of any levers)

• Handle the DSL with care so that the piston rod or

square is not damaged. This applies in particular to the

following points:

• Position the DSL so that you can easily reach the oper-

ating parts.

• Fasten the DSL as follows:

– with at least 2 screws and slot nuts in the groove

aD

on the linear component of the DSL

– on the central nut (M) on the DSL-16

– over a flange (F) on the centring collar on the drive

take-off side of the DSL-20 ... 40.

aD

(M)

(F)

Using the square

aB for optional purposes:

• Avoid lateral forces on the square

aB.

Additional optional purposes are e.g.:

– axial, touching scanning

– axial cushioning.

A light additional element (e.g. a stop or switching cam)

can be mounted on the square.

• When placing the moveable mass, make sure that the

following points are observed:

– the device must not be tilted,

– permissible radial force Fz (diagram below),

– effective power Fx (

Technical data),

– permissible mass moment of inertia (

Technical

specifications).

DSL-16

DSL-20

DSL-25

DSL-32

DSL-40

z

The mass moment of inertia of the moveable mass

should be calculated. Lever arms, jibs and masses,

as well as masses on the square must be taken into

consideration in the calculation.

The permissible mass moment of inertia (

Catalogue

specifications) depends on the specific situation:

– the size of the DSL

– the type of end-position cushioning

– the swivel time

– the swivel angle

– the stroke time

Definition

Swivel time = rotation time of the inner vane +

cushioning time from the shock absorber

DYSC

DSL-…-270-...-B

16

20

25

32

40

DYSC-…

5-5

7-5

8-8

12-12

Cushioning time

[s] 0.1

0.25

0.3

Fastening the work load

• Push the moveable mass onto the piston rod:

• Make sure that the moveable mass cannot slide down

from the piston rod.

The thread in the piston rod serves this purpose.

When tightening the screws, counter-lock at the work

load.

• Note the following tightening torque:

DSL-…-270-...-B

16

20

25

32

40

Tightening torque

[Nm]

1.2

5.5

10

• Note the following correlation of permitted work load

and piston speed v:

Eccentric masses on the horizontal lever arm increase

the inner friction. The effective power of the linear

movement is thereby reduced (not with DSL-...-KF).

DSL-16

DSL-20

DSL-25

DSL-32

DSL-40

4.2 Adjusting the DSL with an internal stop system

Using

external stops and shock absorbers

Note

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

• Make sure that the following points are observed:

– The target point in the mass moment of inertia

(important with eccentric masses on the lever

arm)

– The permitted radial force Fz (

Chapter “Fitting

mechanical components”)

– Using protective devices

(e.g. cover cap

Accessories)

Note

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation without shock absorbers will destroy

the DSL.

1.Remove the protective cap of the DSL from the housing

(if present).

2.Screw the shock absorber elements (elastomer ab-

sorbers or shock absorbers) into the shock absorber

retainer.

The accompanying documentation must be observed.

3.Swivel the moveable mass to the desired end position:

– by hand

– with open-end wrench on the square

aB.

(not with DSL-...-KF)

The angle scale on the housing ring serves as a first

orientation.

DSL-…-270-...-B

16

20

25

32

40

Degree setting (1

graduation =)

[°]

2

1

4.Unscrew the locking screws for the shock absorber

retainers. To shift the shock absorber retainers it is

sufficient to slacken the locking screws until they can

just barely be shifted.

5.If possible use symmetric angle settings that follow line

of symmetry M of the DSL. These produce a more even

movement between right-hand and left-hand rotation.

6.Push the nearby shock absorber retainer towards the

stop lever against the force of the shock absorber until

the fixed stop of the shock absorber (elastomer ab-

sorber or shock absorber) touches the stop lever.

If necessary, counter-lock on the work load.

Note

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shock absorber retainers that are fastened with an

insufficient tightening torque may shift under opera-

ting conditions, resulting in damage to the DSL.

7.Tighten the locking screw of the shock absorber

retainer again with the following tightening torque.

Only with the specified tightening torque will the

toothing of the shock absorber retainer bite into the

housing material.

DSL-…-270-...-B

16

20

25

32

40

Locking screw

M3

M4

M5

M6

M8

Tightening torque

[Nm]

2.1

4.9

10

16.5

40

8.Repeat the adjustment for the other end position.

DSL-16 … 40-270-…-B

Operating instructions

Original: German text

Festo AG & Co. KG

Postfach

D-73726 Esslingen,

Germany

Phone:

+49/711/347-0

www.festo.com

0808a

740 210