Det-Tronics ATX10 Transmitter User Manual

Page 14

2.5

95-8657

12

GREASE/LUBRICATION

To ease installation and future removal, ensure that all

junction box covers and sensor threads are properly

lubricated. If the need arises for additional lubrication, use

either Lubriplate grease (see Ordering Information for part

number) or Teflon tape. Avoid the use of silicone grease.

PROTECTION AGAINST MOISTURE DAMAGE

It is important to take proper precautions during

installation to ensure that moisture will not come in

contact with the electrical connections of the system.

The integrity of the system regarding moisture protection

must be maintained for proper operation and is the

responsibility of the installer.

If conduit is used, the use of proper conduit installation

techniques, breathers, glands, and seals is required to

prevent water ingress and/or maintain the explosion-

proof rating.

Conduit drains must be installed at water collection

points to automatically drain accumulated moisture.

Conduit breathers should be installed at upper locations

to provide ventilation and allow water vapor to escape.

At least one breather should be used with each drain.

Conduit raceways should be inclined so that water will

flow to low points for drainage and will not collect inside

enclosures or on conduit seals. If this is not possible,

install conduit drains above the seals to prevent the

collection of water or install a drain loop below the

detector with a conduit drain at the lowest point of the

loop.

Conduit seals are required for compliance with NEC/

CEC explosion-proof installation requirements and to

prevent water ingress in outdoor applications. Seal all

conduits within 18 inches of the device. Units with M25

threads must use an IP66 rated washer or an IP66 rated

cable gland with O-ring to prevent water ingress.

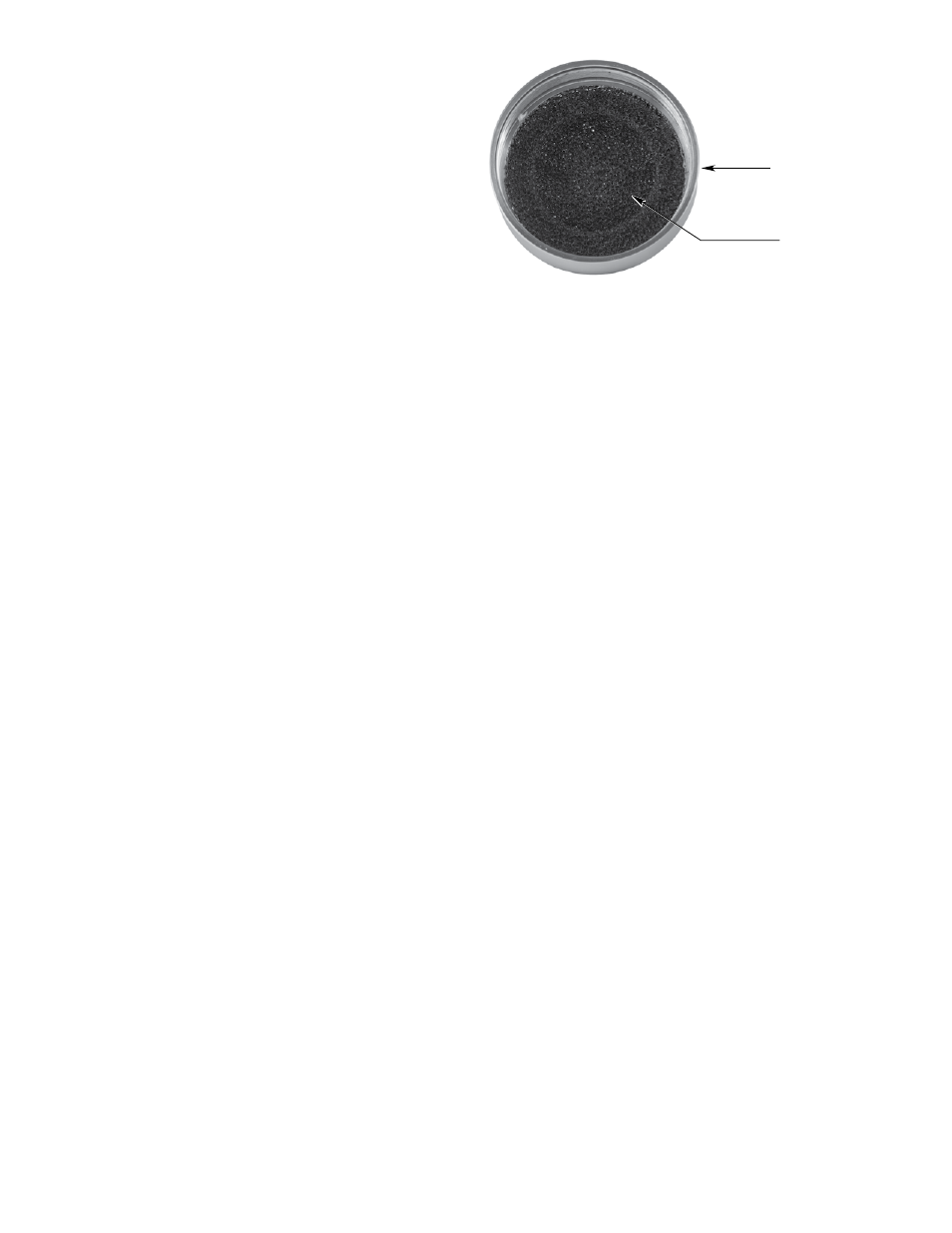

FOAM INSERT

A foam insert (included) is recommended in

applications where wind driven sand or other high

velocity particulates can penetrate the sensor’s

protective cover and cause damage to the microphone

and/or AIC sound emitter.

To install the insert, ensure that the device is powered

off, then remove the protective cover from the sensor

housing by turning counterclockwise (no tools

required). Carefully press the insert inside the cover

(See Figure 7), then re-install the cover on the sensor.

Refer to the Maintenance section of this manual for

additional information regarding the insert.

IDENTIFICATION OF DETECTOR MOUNTING

LOCATIONS

Identification of the most likely leak sources is typically

the first step in determining optimal locations for

acoustic detection.

It is not required to aim the FlexSonic detector toward

a potential leak source. The preferred orientation for

the AC100 Acoustic Sensor is positioned vertically

downwards.

It is recommended that the acoustic detector be

mounted at or above the level at which the potential leak

is likely to occur.

If the installation requires mounting the detector close

to ground level, note that the effective detection range

may be reduced due to the potential effects of ground

absorption and reflection.

The most effective number and placement of detectors

varies depending on the conditions on site. The individual

designing the installation must often rely on experience

and sound judgment to determine the detector quantity

and best locations to adequately protect the area. Note

that it is typically advantageous to locate detectors

where they are accessible for maintenance.

To facilitate improved viewing with various installation

orientations, the ATX10 faceplate can be rotated in

90 degree increments. Access the ATX10 faceplate

by unscrewing the cover and pulling the transmitter

module from the mounting posts that secure it to the

junction box, then reposition it as desired. Note that the

module is held in place by a compression fitting – no

screws are involved.

Figure 7—Foam insert installed inside Sensor Cover

SENSOR COVER

FOAM INSERT

A2616