Known thickness, One point calibration – Dakota Ultrasonics CMX DL User Manual

Page 79

CMX

DL

High Performance Material & Coating Thickness Gauge

75

Known Thickness

Sometimes the sound velocity of a coating material is unknown. In this case a

sample with a known thickness can be used to determine the sound velocity of the

coating. As previously discussed, the CMX

DL

offers a one point calibration option for

coating in PECT measurement mode. It is also import to reiterate that the coating

sample must be coupled to a metallic material in order to perform the calibration.

The calibration should also consider calibrating on high side of the intended

measurement range, when using the one point option, minimize overall error. For

example, if the measurement range of the coating will be from .040” - .080” (1.0mm

2.3mm), a coating closest to .080 (2.0mm) should be used. Note: It’s always handy

to carry a set of mechanical calipers to use in conjunction with the CMX

DL

for

calibration in the field:

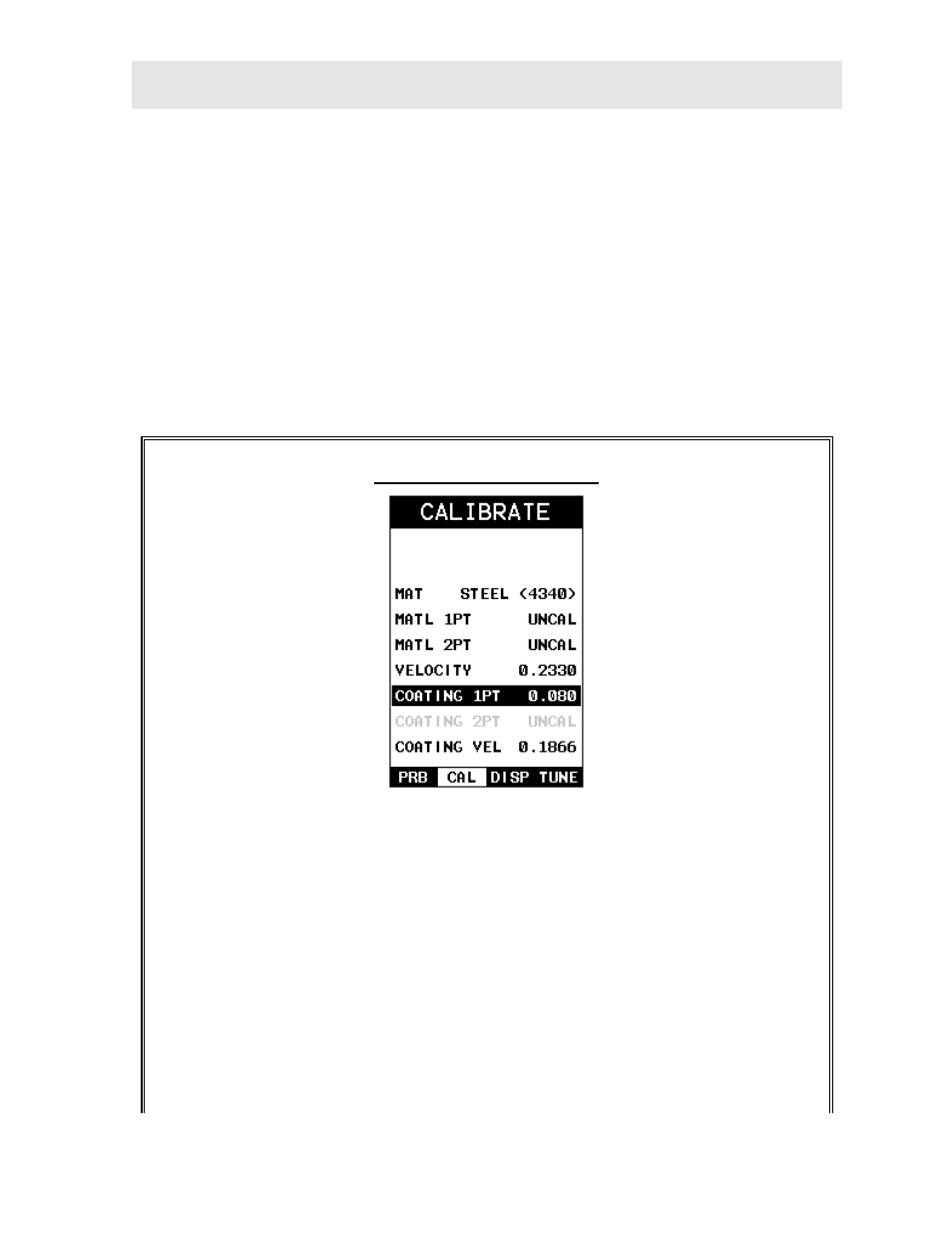

One Point Calibration

Note: Be sure that the probe zero procedure has been performed prior to

performing this calibration procedure.

1) Physically measure an exact sample of the coating using a set of calipers or

a digital micrometer.

Note: The coating sample must be coupled to a metallic material in order to be

calibrated.

2) Apply a drop of couplant on a piece of metal and place the coating sample

on the metal over the couplant. Apply a drop of couplant on the transducer