Two point calibration – Dakota Ultrasonics CMX DL User Manual

Page 55

CMX

DL

High Performance Material & Coating Thickness Gauge

51

the job. For example, if the measurement range was .080” (2.03mm) to .250”

(6.35mm), the user would perform a one point calibration on a known thickness

sample close to .250” (6.35mm), followed by a two point calibration close to .080”

(2.03mm). When a two point calibration is performed, the CMX

DL

calculates the zero

and the velocity. The following steps outline this procedure:

Two Point Calibration

1) Physically measure an exact sample of the material or a location directly on

the material to be measured using a set of calipers or a digital micrometer.

2) Apply a drop of couplant on the transducer and place the transducer in

steady contact with the sample or actual test material. Be sure that the

reading is stable and the repeatability indicator, in the top left corner of the

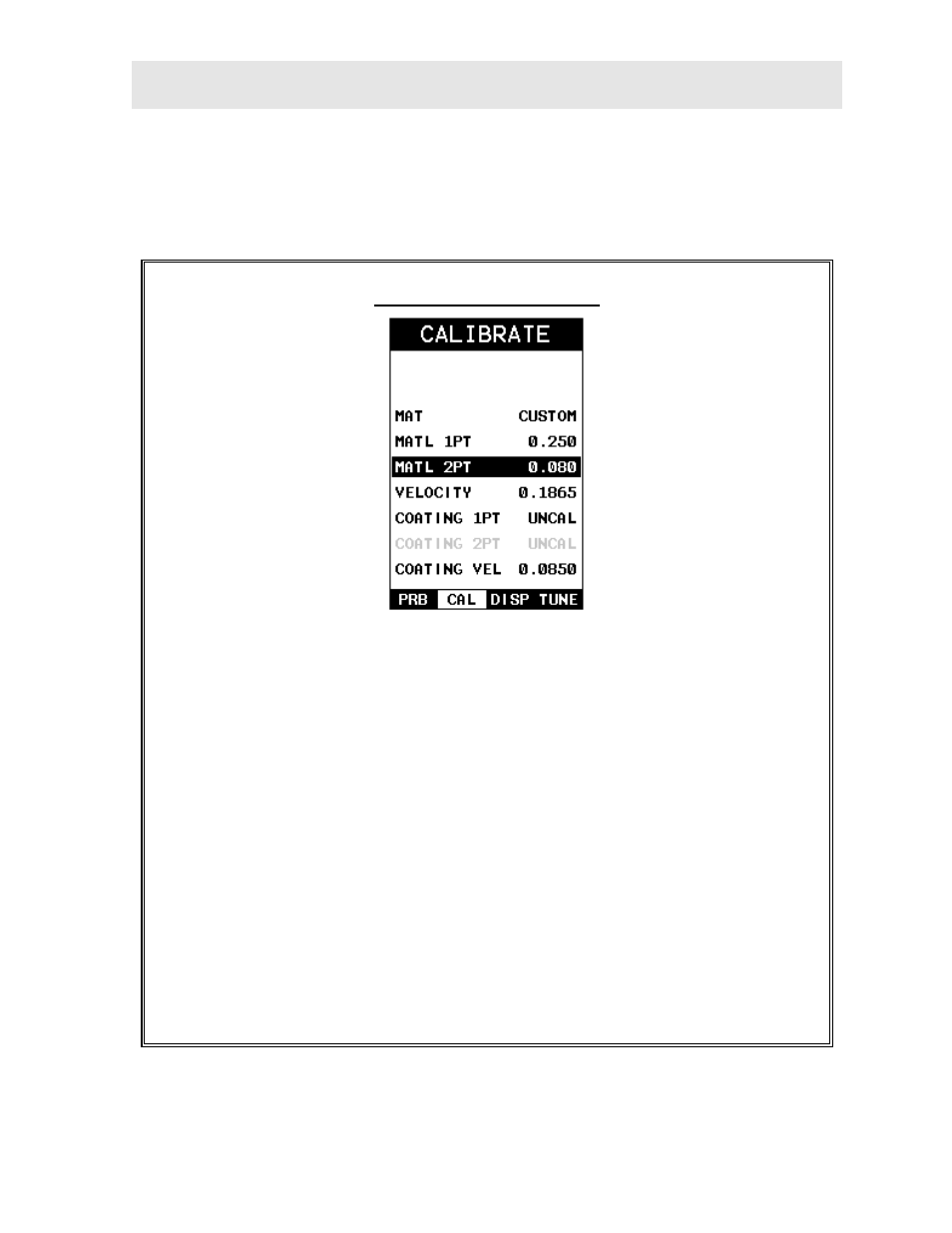

display, is fully lit and stable. Press the MENU key once to activate the

menu items tab. Press the MENU key multiple times to tab right and the

ESC key multiple times to tab left until the CAL menu is highlighted and

displaying the submenu items.

3) Use the UP and DOWN arrow keys to scroll through the sub menu items

until MATL 2PT is highlighted.