2 probe – menu, 3 cal – menu – Dakota Ultrasonics CMX DL User Manual

Page 28

Dakota Ultrasonics

24

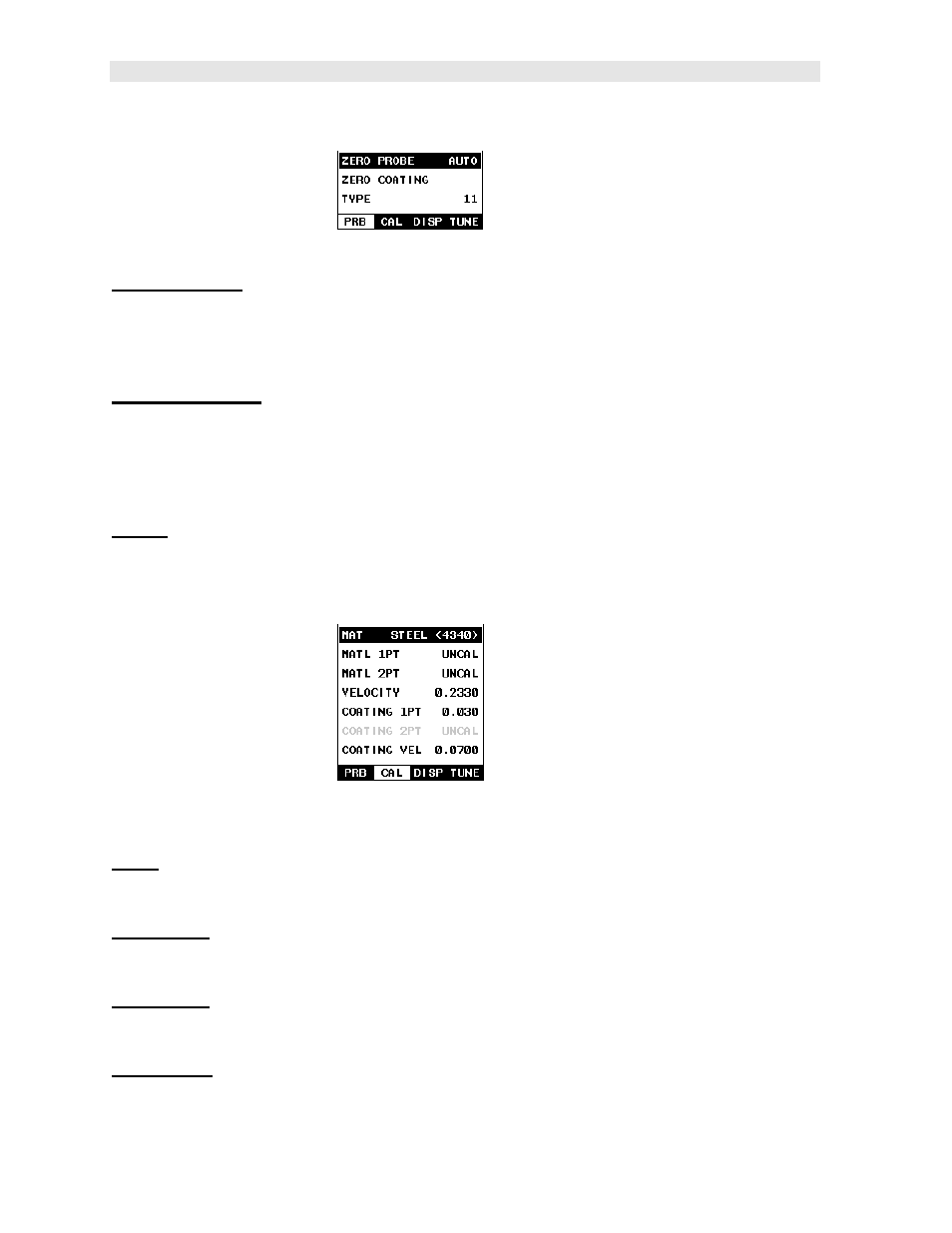

3.2 Probe – Menu

ZERO PROBE: The CMX

DL

is zeroed in much the same way that a mechanical

micrometer is zeroed. If the CMX

DL

is not zeroed correctly, all of the measurements

made using the CMX

DL

may be in error by some fixed value. The CMX

DL

is equipped

with an optional automatic or manual zero feature. Refer to the section on page 43,

for an explanation of this important procedure.

ZERO COATING: In order to account for very slight electronic differences in

transducers of the same type, frequency, and diameter, the CMX

DL

has been

equipped with a “zero coating” feature. This enables the CMX

DL

to obtain very

accurate readings on coatings, eliminating potential e rrors incurred from slight

differences in the manufacturing processes. Refer to the section on page 43, for a

detailed explanation.

TYPE: Enables the user to select the type of transducer being used from a chart of

transducer types. This provides increased linearity between transducers. Refer to

page 39 for a further explanation.

3.3 CAL – Menu

MAT: Select the material velocity from a chart of basic material types when a known

sample thickness, or material velocity cannot be obtained. Refer to page 52 for

further info.

MATL 1PT: Performs a single point calibration. This option allows the user to

automatically calculate the velocity by entering a known sample thickness. Refer to

page 49 for further info.

MATL 2PT: Performs a two-point calibration. This option allows the user to

automatically calculate the velocity by entering a second known sample thickness.

Refer to page 51 for further info.

VELOCITY: Function to calibrate the CMX

DL

by setting the velocity to a known

material velocity. Refer to page 46 for further info.