Danger caution – COATS Pit Tire Changer User Manual

Page 16

G. On a daily basis, inspect the unit and check to be

certain that all systems are operating normally.

Detailed inspection and testing procedures are speci-

fied for various components at regular intervals. Set up

a chart and assign responsibility for these items.

Replace any damaged or missing safety

decals. They are available from COATS, (800)

688-6359.

Important: These instructions will help you service

the unit. Instructions are for a person with some

mechanical ability and training. No attempt has been

made to describe all basic steps. For example, how to

loosen or tighten fasteners. Also basic procedures

such as cycling systems and checking operation of the

equipment are not fully described since they are

known to anyone who does mechanical and service

work. Do not attempt to perform work beyond your

ability or at which you have no experience. If you need

assistance, call an authorized service center or contact

COATS directly, (800) 688-6359.

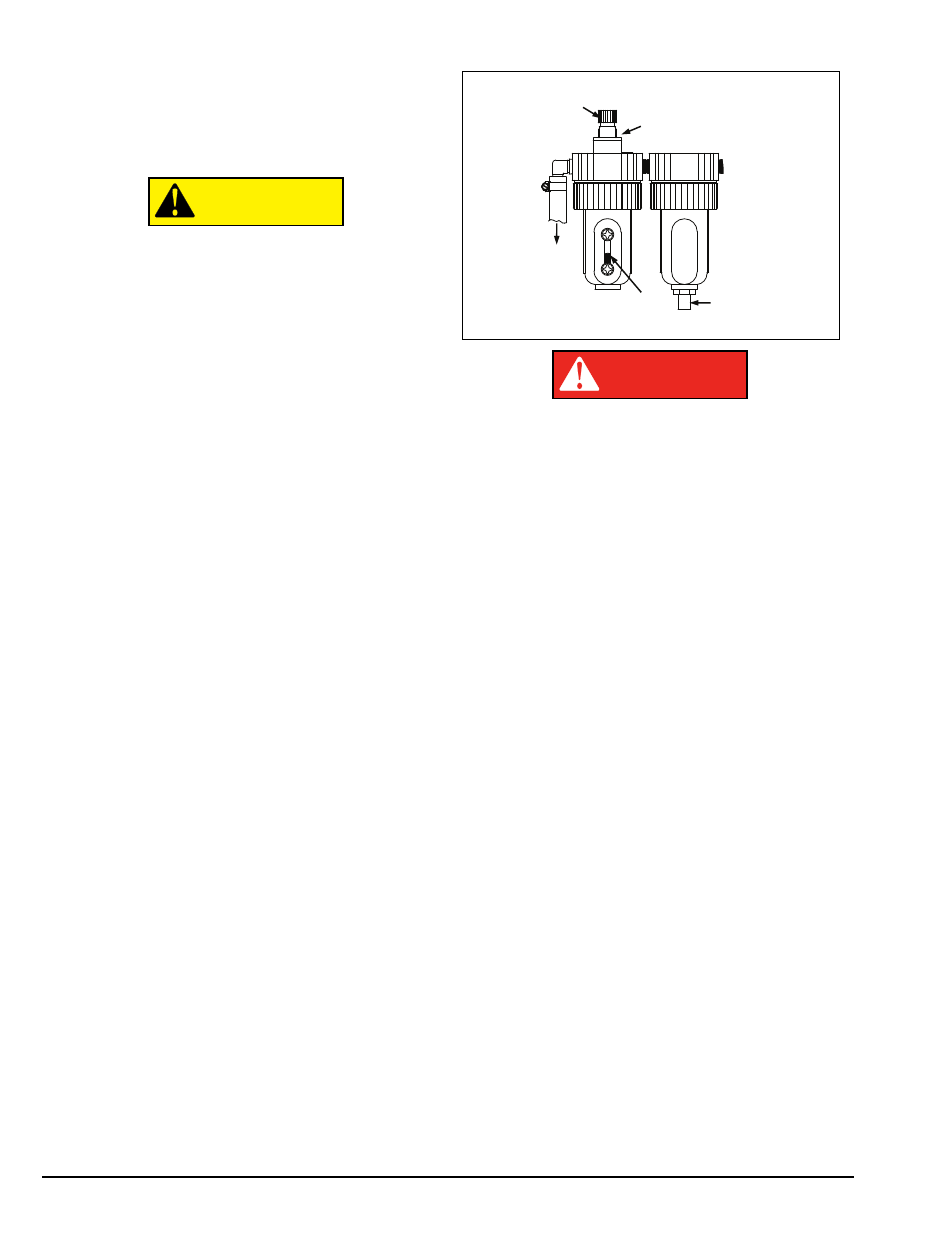

Separator/Lubricator Maintenance

Check oil and water levels regularly, and perform

these maintenance items weekly:

A. Disconnect air supply to machine.

B. The Separator (Filter) unit is equipped with an auto-

matic drain and should not normally need draining.

C. If the fluid level is greater than 1/4" from the top of

the gauge, add oil. Remove the filler plug on top of the

lubricator and add SAE 10W non-detergent oil or an air

tool oil to bring the level up to 1/4" from the top of the

gauge. Replace filler plug and clean up any spilled oil.

D. Adjust the oil flow by turning the black flow adjust-

ment knob and turning it to increase or decrease the

flow. Watch the formation of oil drops in the see-

through oil chamber. Reconnect the air supply and con-

tinually cycle the bead loosener through full strokes

and count the drips during the cycles. The delivery of

oil to the airline should be about 1 drop per 10 cylinder

cycles. Adjust flow as required.

Never inflate tire above manufacturer’s rec-

ommended pressure after bead is seated.

Any required inflation above 60 PSI should

be performed in an inflation chamber/safety

cage or securely mounted on the vehicle if

an inflation chamber is not available. A tire

explosion may cause personal injury or

death to operator or bystanders.

Air Source

This model requires a a 5 CFM air source at 150 PSI.

The operating pressure range for all models is between

125 PSI and 175 PSI at the machine.

Electrical Source

Electric models require power from a 30 amp, 120

volt electrical circuit. Have a licensed electrical techni-

cian perform any necessary changes to the power

source before plugging in the unit. The electrical source

must have a solid connection (less than 1 ohm)

between ground and building ground.

DANGER

CAUTION

12 •

Important: Always read and follow the operating instructions.

Oil Flow

Adjuster

Knob

Air Out

Reg

G

Auto Drain

Outlet

Separator

Lubricator

Oil Fill

(Behind Oil

Flow Adjuster)

Oil Level

Check

A

Regu

Adjus

Kn

Air Out