Warning, Warning danger, Danger – COATS Pit Tire Changer User Manual

Page 14

10 •

Important: Always read and follow the operating instructions.

Bead Sealing

1. Position valve stem in front of operator and con-

nect the inflation hose with the clip-on chuck. Be sure

tire’s top bead does not cover the bottom of the valve

stem

2. Depress inflation pedal to position 2 and hold

about five seconds to begin air flow through tire valve.

3. Release the inflation pedal and allow it to return to

position 1. Verify that beads are completely sealed to

the wheel. Repeat these steps if beads have not

sealed. It may be necessary to wait a few seconds for

the air storage tank pressure to recover before

attempting again.

S. If tire and wheel are properly lubricated and

operator cannot achieve bead seal after three

or four attempts, the valve core may be

removed from the valve stem to allow more air

flow into the tire to assist with bead seal. After

bead seal is achieved, remove the clip-on

chuck and reinstall the valve core. Reattach the

clip-on chuck after core is installed.

Bead Seating

NEVER exceed 40 PSI to seat beads while

using this tire changer. If more than 40 PSI is

permitted by tire manufacturer, ALWAYS use

safety cage and clip-on chuck. NEVER

exceed recommended pressure after seat-

ing beads. ALWAYS keep hands and entire

body back from inflating tire.

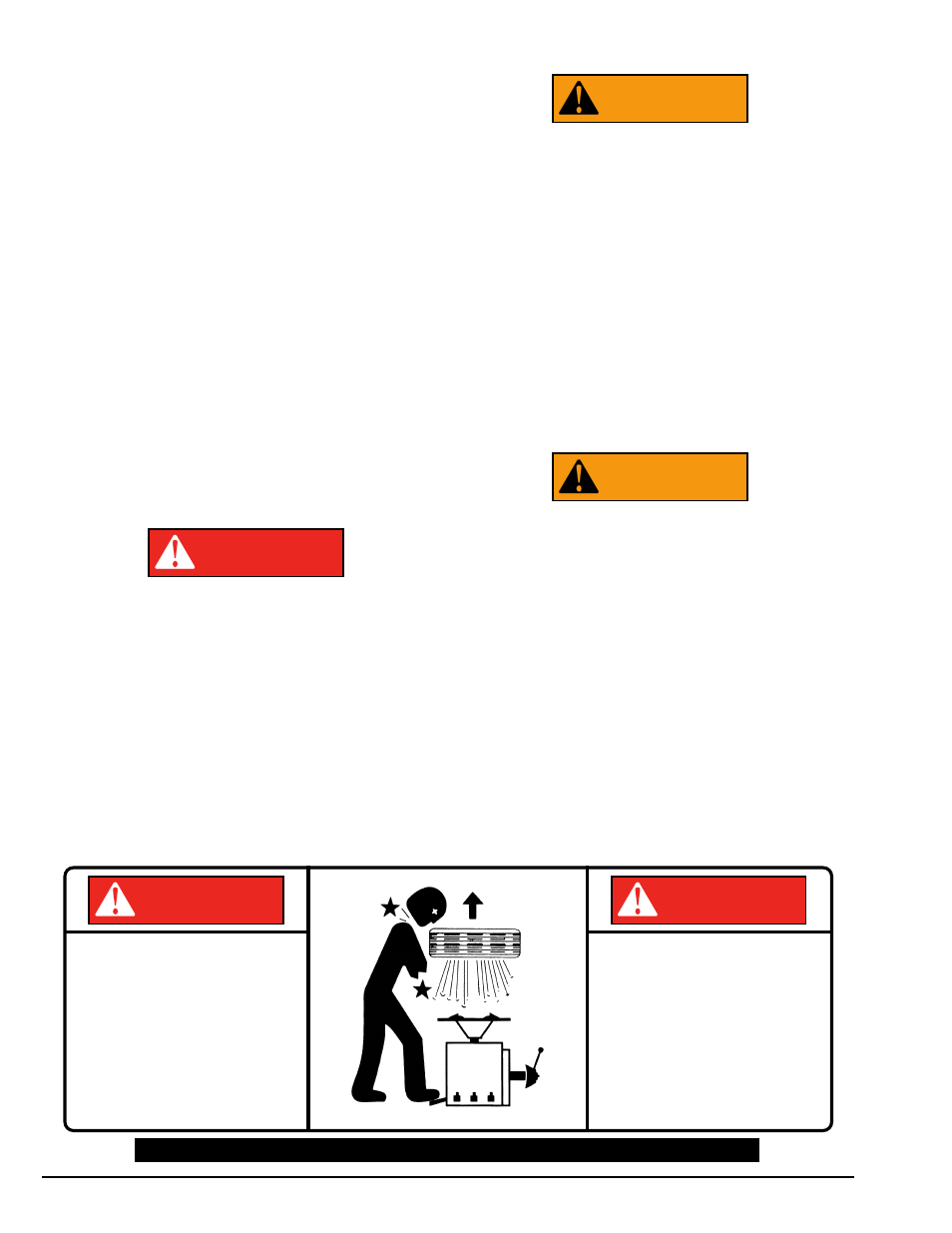

An exploding tire, wheel, or bead sealing

equipment may propel upward and out-

ward with sufficient force to cause serious

injury or death to operator or bystander.

Check tire pressure frequently. If operator is

unable to obtain Bead Seat, something is

wrong. Deflate tire completely, inspect tire

and wheel, correct any problems found,

relubricate both tire beads, and reattempt

Bead Seal and Seat procedures. Follow all

safety instructions in this manual and on

machine.

1. Once tire pressure is indicated on the air gauge

(inflation pedal in position 1; foot removed from pedal),

continue to inject air into the tire (inflation pedal posi-

tion 2) in short intervals. Check the pressure fre-

quently. Stand back during bead seat. Keep hands,

arms, and entire body away from tire during this pro-

cedure.

Inflation

NEVER exceed tire manufacturer's recom-

mended air pressure. Tires can explode,

especially if inflated beyond these limits.

Use clip-on air chuck, keep hands, arms and

entire body back from inflating tire. Avoid

distraction during inflation. Check tire pres-

sure frequently to avoid over inflation.

Excessive pressure can cause tires to

explode, causing serious injury or death to

operator or bystander.

1. Make sure both beads are seated. When both

beads are seated, the tire is ready for inflation.

2. Replace the valve core if it was removed.

3. Depress the inflation pedal to position 2 to inflate

the tire.

WARNING

WARNING

DANGER

Explosion Hazard

Never inflate tire

above

manufacturer's

recommended

pressure after bead

is seated.

DANGER

Explosion Hazard

Never exceed 40

PSI while seating

beads.

Remember R.I.M.

(see page iv and back cover)

DANGER

Remember R.I.M.

(Read, Inspect, Mount)

for every tire.