Robo-arm, Caution, Servicing custom wheels with the robo-arm – COATS Kit 8184177 Robo-Arm and Accessory Kits User Manual

Page 3

Robo-Arm™

COATS Robo-Arm™ Assembly • 3

Servicing Custom Wheels

with the Robo-Arm™

This accessory is normally used in the servicing of performance

and large heavy tires and wheel combinations.

Only tire technicians with experience and training on

custom wheels should attempt to service expensive

custom alloy or aluminum wheels and high-perform-

ance low-profile tires.

Pre-Operation Notes:

• Ensure all weights have been removed.

• Clamp wheel from the outside.

• Use ample lubricant for mount and demounting

• Always review wheel nicks and/or scratches with the owner

before servicing.

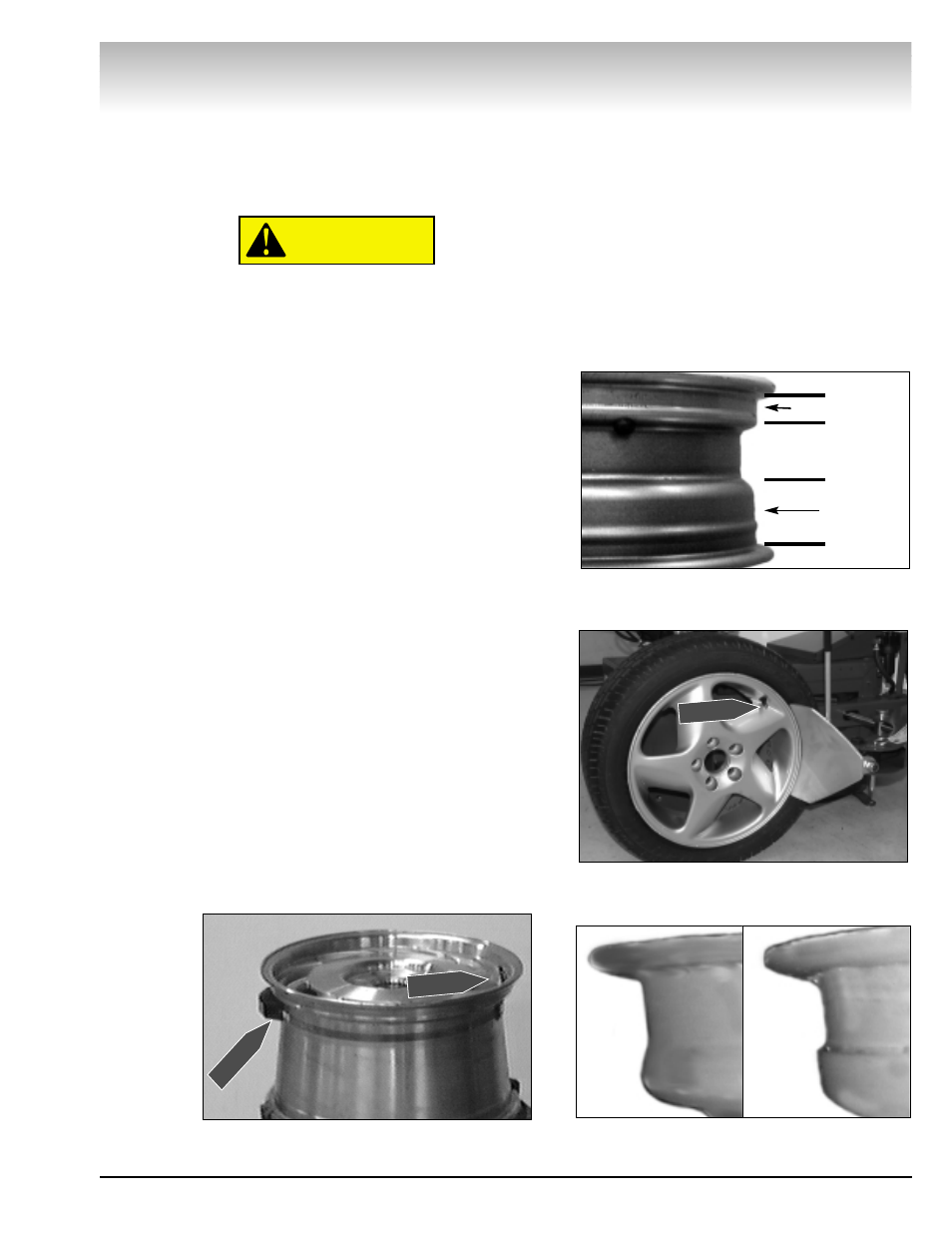

Performance Tires and Wheels • Demounting

Follow these instructions for performance type tires and

wheels, including run-flat tires and their associated wheels, and

asymmetrical hump wheels.

1. Remove valve core and completely deflate tire.

2. Pull the bead loosener shoe away from the machine and roll

the tire into position against the bumper pads. Position the tire

with the valve stem in the 2 o'clock position (in direct line with

the bead loosener shoe). Always loosen the bead on the nar-

row/mounting side of the wheel first (Figures 1 and 2).

AA: Wheels with an asymmetrical hump have a larger “ledge”

type hump around the wheel except at the valve hole making

them more difficult to mount and demount (Figure 3). Always

loosen the beads near the valve stem on both sides of rim first.

AB: Some wheels/tires have a low pressure sensor/transmitter

strapped to the wheel (Figure 4). This is especially true on run-flat

tire/wheel systems. The sensor is positioned directly opposite

from the valve stem. Other low pressure warning systems have

the sensor as part of the valve. To avoid damaging the sensor,

CAUTION

Valve Stem

Figure 2 - Position Tire for Bead Loosening

Figure 1 - Determining Mounting Side of Wheel

Narrow Side

Long Side

Drop Center

Smooth

Hump

At Valve

Hole

Ledge

Hump -

Rest of

Wheel

Valve Stem

Sensor

Figure 4 - Wheel with Low Pressure

Sensor/Transmitter

Figure 3 - Asymmetrical Hump Wheel