COATS 6275HS Truck Wheel Balancer User Manual

Page 7

I 0708

-

6

16

9

7

15

13

10

14

12

6

6

6

1

2

3

4

8

6

11

5

17

18

GB

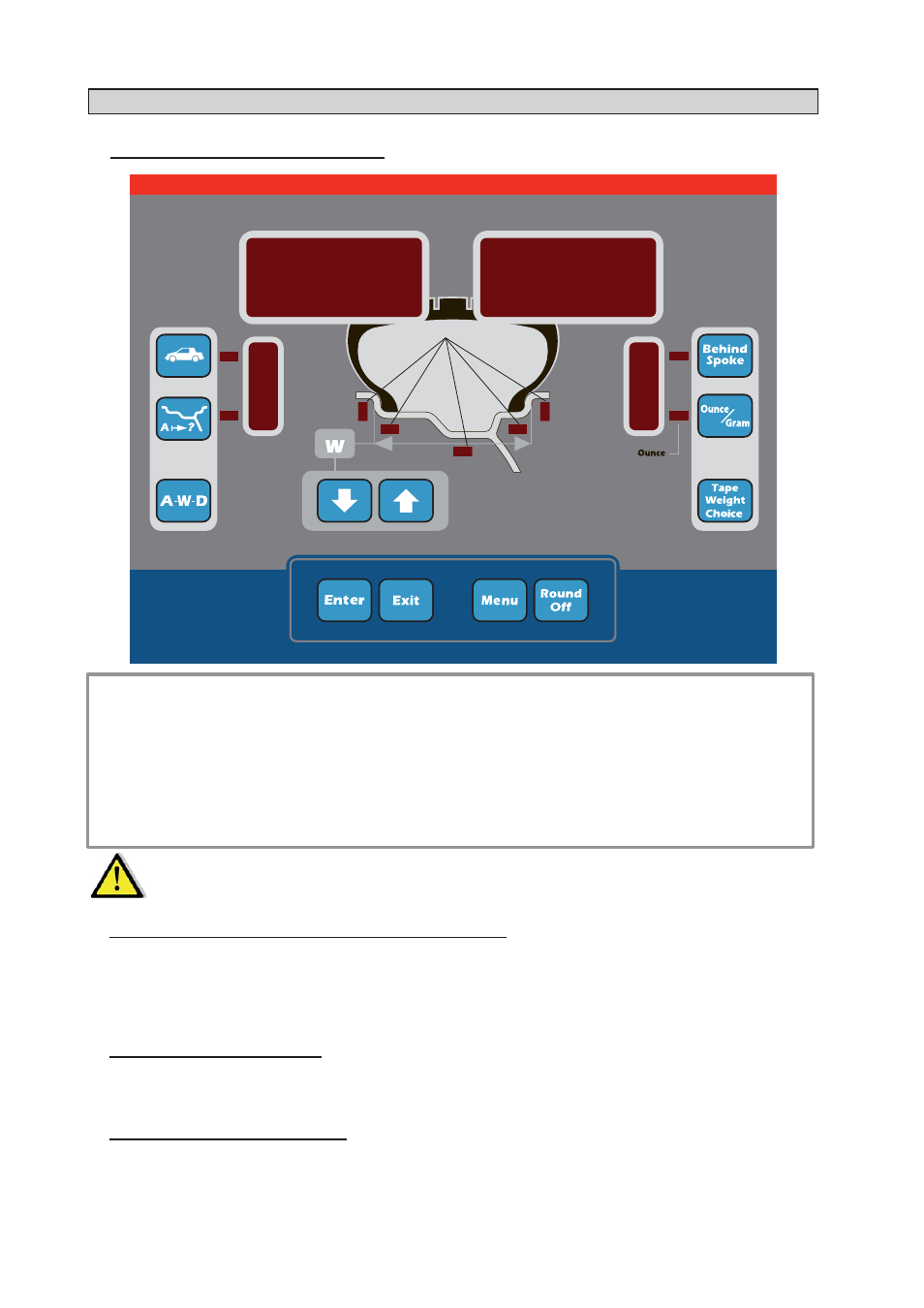

4 - CONTROLS AND COMPONENTS

4.1 - CONTROL PANEL AND DISPLAY

►

1-2

Digital readouts, AMOUNT OF UNBALANCE,

inside/outside

3-4

Digital readouts, POSITION OF UNBALANCE,

inside/outside

5

Indicators, correction mode selected

6

Indicators, selection made

7

SPLIT push button (unbalance resolution)

8

Push button, ounces/grams selection

9

Push button, selection of mode of correction

10

Push button, car/truck selection

11 Position

repeat

12

Push buttons, manual dimensions setting

13

Push button, menu selection confi rmation

14

EXIT/emercency push button

15

Push button, FUNCTIONS MENU

16

Push button, unbalance reading < 5 g (0.25 oz)

17

Minimize/MENU button

18

Maximize/MENU button

O

N

▪

LY

USE

THE

FINGERS

TO

PRESS

THE

PUSH

BUTTONS

.

N

EVER

USE

THE

COUNTERWEIGHT

PINCERS

OR

OTHER

POINTED

OBJECTS

.

▪

4.2

►

- AUTOMATIC DISTANCE AND DIAMETER GAUGE

This gauge allows measurement of the distance of the wheel from the machine and the wheel diameter at the point

of application of the counterweight. It also allows correct positioning of the counterweights on the inside by using the

specifi c function (see

INDICATION OF EXACT CORRECTION WEIGHT POSITION

) which allows reading the position used

for the measurement within the rim.

4.3 - WHEEL LIFTING LEVER

►

Allows lifting the wheel from the ground without using a lift in order to spin it.

It also allows lowering the wheel until it touches the ground in order to stop rotation.

4.4 - MANUAL SPINNING LEVER

►

Allows spinning the tyre. When the machine display turns off, it means that the minimum spindle rotation speed has

been reached to perform correct balancing (70 rpm. for trucks and 100 rpm. for cars). At this point, release the handle

and wait until the unbalance measured appears on the display. If the beep function is enabled (see

MENU

), a beep

will sound when the correct balancing speed is reached.