Calibration – COATS 1250 Series Balancer User Manual

Page 23

Important: Always read and follow the information box instructions.

• 17

Calibration

Machine Calibration

Important: Be sure to use the correct calibration

weight amount: a 4-ounce calibration weight in ounce

mode or a 100-gram calibration weight in gram mode

Important: Starting with software revision 2.0.1.9,

the factory default is set for a 4-ounce calibration

weight amount for both the ounce and the gram

weight measurement modes. Therefore, for Machine

Calibration, only the 4-ounce calibration weight is nec-

essary regardless of the weight measurement mode

setting.

To use a 100-gram calibration weight amount, when

first prompted to use the 4-ounce weight in calibration

mode, press the gram/oz key (SHIFT 9) to toggle from

4.00 to 100. Once set, the balancer retains this new

default preference in memory.

Important: Starting with software revision 2.0.1.6,

the user is only required to enter the D dimension.

Note that prior software versions still require that the

user enter all the DIMS (A, W, and D wheel dimen-

sions).

1. Mount a 16-inch steel tire/wheel assembly on the

balancer. A balanced tire/wheel is required.

Note: Position wheel so that no weights are on either

flange at the top-dead-center location. Turn the

machine OFF then ON.

2. Press and hold the SHIFT key and press 1 to select

the CAL MACHINE mode.

3. Enter the D dimension.

4. Lower the hood and press START.

5. After spin, raise the hood. Rotate wheel until the

outboard center bar blinks; attach calibration weight to

the outside flange at top-dead-center.

Figure 20 - Calibration Weight On Outside Flange At Top-

Dead-Center

6. Lower the hood and press START.

Important: It is critical that the inner weight be

placed accurately to achieve proper calibration. If the

calibration weight is not moved from the outside

flange directly across to the inside flange, an inner

weight placement error will occur. To correct, follow

the information box instructions.

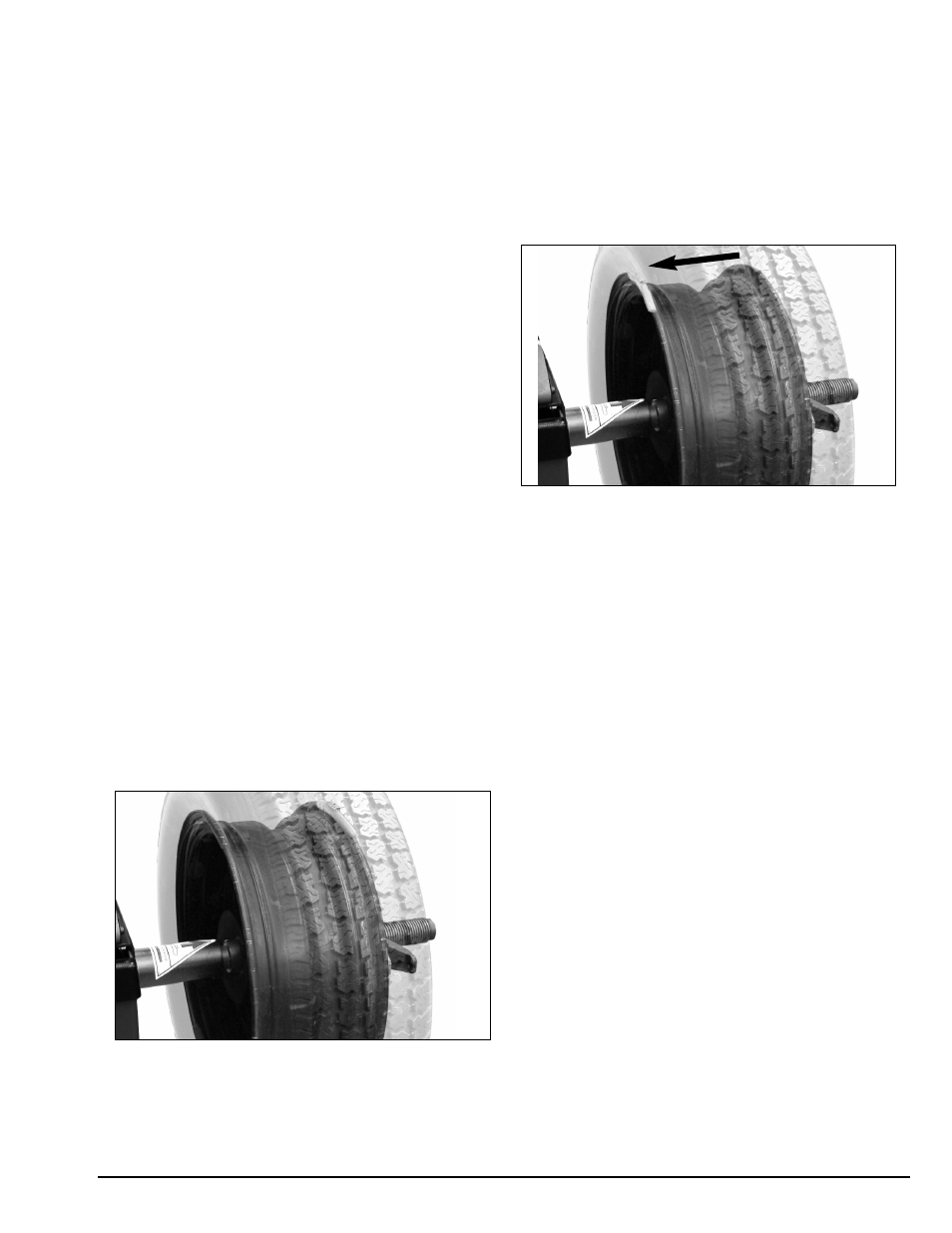

7. After spin, raise the hood. Rotate wheel until the

inboard center bar blinks; move and attach the calibra-

tion weight to the inside flange at top-dead-center.

Figure 21 - Calibration Weight Moved (Directly Across) To

Inside Flange

8. Lower the hood and press START.

9. Calibration complete. Press NEXT.

Arm Calibration

Important: Always perform the Arm Calibration

immediately after Machine Calibration. The balancer

software will not permit it otherwise.

During Machine Calibration, the balancer software

calculates both the A and W dimensions. The Arm

Calibration gives the balancer software a reference

point to the edge of the faceplate and home position.

When the user enters the A dimension from the arm

rod, it calculates the difference from the machine cali-

bration A and uses that as a factor for the manual A

entry. Arm calibration also gives the D dimension a ref-

erence point from home position.

Note: Starting with software revision 3.0.0.0, CdE

will not appear in the INBOARD weight display and the

user is no longer required to enter the Code 96. Note

that prior software versions still require that the user

enter the Code 96 at the CdE prompt to access the

Arm Calibration mode.

1. Complete the Machine Calibration procedure (see

page 17).

2. Press and hold the SHIFT key and press 3 to select

the CAL ARM mode.