Caution, Operating the balancer – COATS 1175 Series Balancer User Manual

Page 9

Important: Always read and follow the instructions.

• 3

Operating the Balancer

Wheel Mounting

Select the most appropriate mounting method for the

wheel you are balancing. Using the proper method

ensures secure mounting and safe balancer operation,

and prevents damage to the wheel.

On most wheels, the inner side of the wheel hub

usually has the most uniform surface for wheel bal-

ancing. Always center the wheel by the most uniform

shaped side of the hub to achieve the most accurate

balance.

Regardless of mounting type, always make sure that

the wheel is forced firmly against the shaft faceplate

and that the hub nut engages the threaded shaft for at

least four complete turns. To assist in centering the

wheel properly, rotate the wheel and the shaft while

tightening the hub nut.

Failure to tighten the hub nut properly may

result in the wheel dismounting, causing

personal injury and property damage.

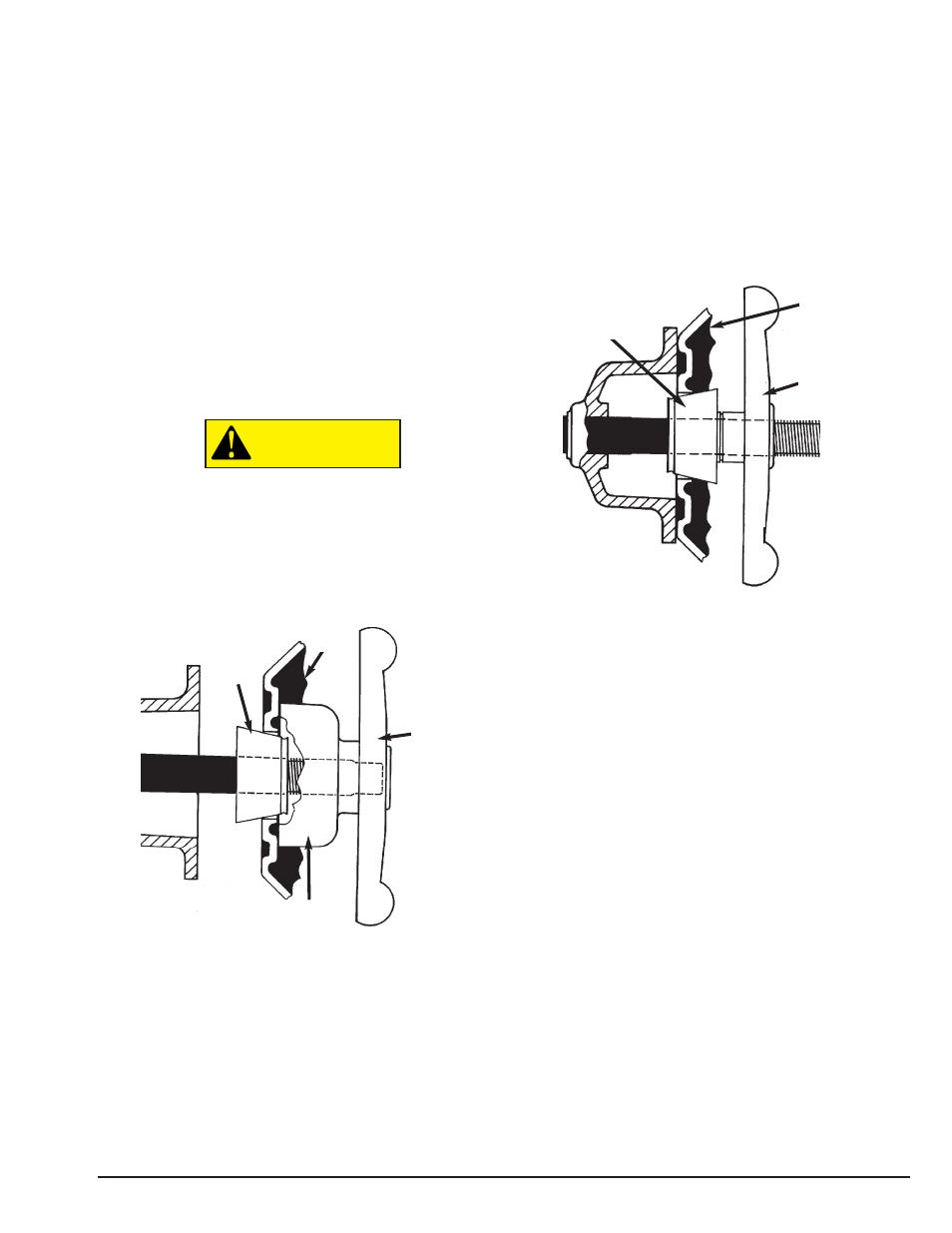

Standard Back Cone Mounting

Most original equipment and steel wheels can be

mounted properly using this method. The wheel is cen-

tered on a cone from the inner side of the hub.

Back Cone Mounting

1. Select the cone that best fits the center hole in the

wheel. Slide the cone onto the shaft with the large end

towards the faceplate.

2. Lift wheel onto the shaft and center it on the cone.

3. Attach the pressure cup to the hub nut and install

the assembly onto the shaft. Tighten securely.

Note: Use a nylon spacer (no mar ring) to protect cus-

tom wheel finishes.

4. Thread the hub nut onto the shaft, and tighten it

against the wheel. The wheel must be forced firmly

against the faceplate. The hub nut must engage the

threads for at least three full turns.

Note: If the hub nut will not tighten completely, use

the front cone mounting method.

Standard Front Cone Mounting

A wheel should be centered by the outer side of the

hub only when the inner surface will not provide an

accurate surface to center on.

Front Cone Mounting

1. Select the cone that best fits the center hole in the

wheel.

2. Lift the wheel onto the shaft and slide it back

against the shaft faceplate.

3. Slide the cone onto the shaft and into the center

of the wheel. You will need to lift the tire to seat the

cone in the center hole.

4. Install the hub nut (without pressure cup) onto the

shaft. Tighten it securely against the cone. The hub nut

must engage the threads for at least three full turns.

Note: If the hub nut will not tighten completely

because of a lack of threads, use an additional cone as

a spacer between the mounting cone and the hub nut.

The wheel must be forced firmly against the faceplate.

CAUTION

Cone

Pressure Cup

Rim

Hub Nut

Rim

Hub Nut

Cone