Pr el im in a ry – Clarus Environmental Fusion Series Treatment Systems 450/600/800 User Manual

Page 9

9

© Copyright 2012. All rights reserved.

PR

EL

IM

IN

A

RY

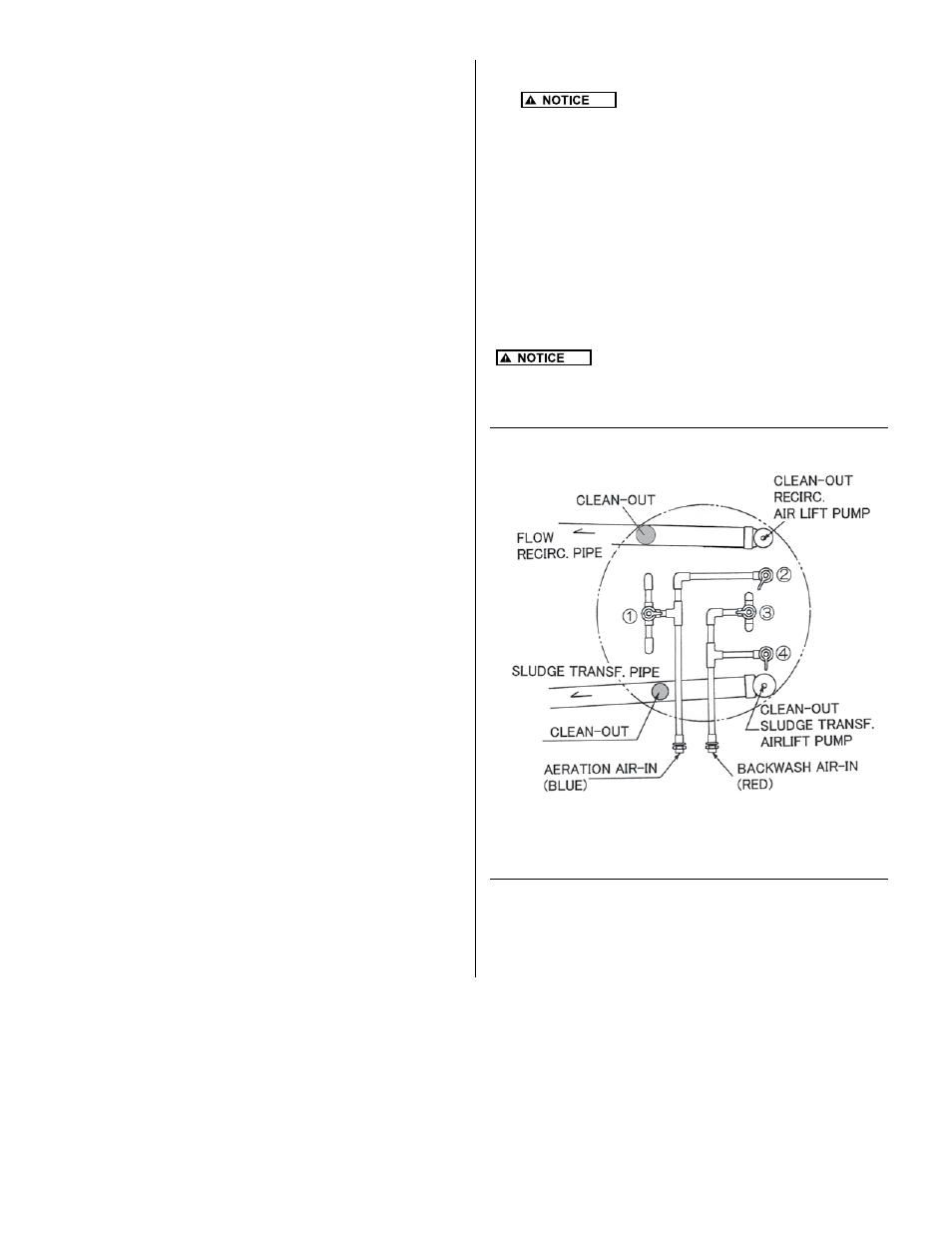

There are two aeration systems provided within the aeration

chamber: normal aeration and backwash. Valves (1 and 3) are

set at 50%. Observe the air flow on each side of the unit to verify

equal flow. If there is an obvious discrepancy in air flow between

the two sides, adjust the valves (1 and 3) so that the flow is equal.

Figure 13- Aeration Flow Adjustment

1. Connect house sewer pipe or septic tank outlet, if

required, to the unit inlet. Make certain only household

waste enters the unit (no foundation drains, gutter

drains, floor drains, etc.).

2. Connect the outlet pipe to the outlet of the unit.

PIPING INSTALLATION

HIGH WATER ALARM FLOAT INSTALLATION

The Fusion

®

alarm panel assembly includes a high water

alarm float switch that is used to monitor the liquid level in

the Fusion

®

unit. The switch should be tethered to one of

the gray, vertical air lines in the aeration chamber. With

a 3" (76 mm) tether length, the cord should pass through

the opening in the partition wall between the aeration and

anaerobic chamber and allow the float to hang in the outlet

baffle of the anaerobic chamber.

1. The float switch should be tethered to one of the gray,

vertical pipes in the aeration chamber. When the float

is in the horizontal position, the cord should be at

least 1" (25 mm) below the top of the partition wall

opening in the anaerobic chamber baffle.

2. Place the cord into the clamp and secure to gray aeration

pipe. NOTE: Do not install the cord under the clamp.

3. Position the float with a 3" (76 mm) tether.

4. Tighten the clamp with a screwdriver. Be careful not

to overtighten as this may cause damage to the plastic

clamp.

5. Make sure the float cord is not allowed to touch the

excess clamp band during operation as this may

cause damage to the cord.

6. The float switch cord should be installed in an electrical

conduit connecting the alarm panel to the Fusion

®

unit.

The electrical conduit must be rated for burial, and should

be properly sealed to prevent gases from entering the

alarm panel.

7. A ½" (13 mm) bulkhead fitting (supplied by others)

should be used to connect the electrical conduit to the

Fusion

®

unit. A hole must be drilled through the wall of

the Fusion

®

unit between the red and blue bulkhead

fittings to facilitate this connection.

8. Please be certain that the bulkhead fitting for the

electrical conduit forms a watertight connection with the

FRP wall of the Fusion

®

unit.

9. Electrical conduit from the Fusion

®

unit to the alarm

panel can be buried in the same trench as the air lines.

10. The control switch can be wired directly into the alarm

panel. See Figure 7.

1.

All electrical installations must follow

the National Electrical Code and/or your local/state

electrical codes.

2. The blower should be directly wired into the alarm panel.

The alarm panel must be located in a dry location that

is accessible for maintenance. Please see Figure 7 and the

wiring diagram and instructions enclosed with the alarm panel.

3. Make certain the timer within the control panel is set to

the proper time. The timer unit display should be set to

10 hrs. and the timer dial needle set to 3.6 for 36 hours.

This will activate an alarm if the blower doesn't go into

backwash cycle within a 36-hour time frame.

ELECTRICAL CONNECTIONS

START UP

An installation and start-up check list (CL0057)

is furnished with the information package in the blower box.

Please use this as a guide and fill out all sections and return

to your distributor.

Valve Legend:

1. Aeration

Blue

3. Backwash

Red

2. Recirculation

Gray

4. Sludge transfer Gray