Pr el im in a ry – Clarus Environmental Fusion Series Treatment Systems 450/600/800 User Manual

Page 10

10

© Copyright 2012. All rights reserved.

PR

EL

IM

IN

A

RY

The recirculation flow is designed to be 1.2-1.8 times that

of the average design inflow. Table 4 indicates starting

flow rates for each unit. However, fine adjustments may be

necessary to ensure optimum performance.

Setting the flow rate:

• Adjust the flow using rates in Table 4.

• The flow rate is adjusted by rotating the gray recirculation

valve (2) and observing the flow at the pipe end.

• There are prescribed lines at the outlet of the recirculation

pipe to aid in approximating the correct flow.

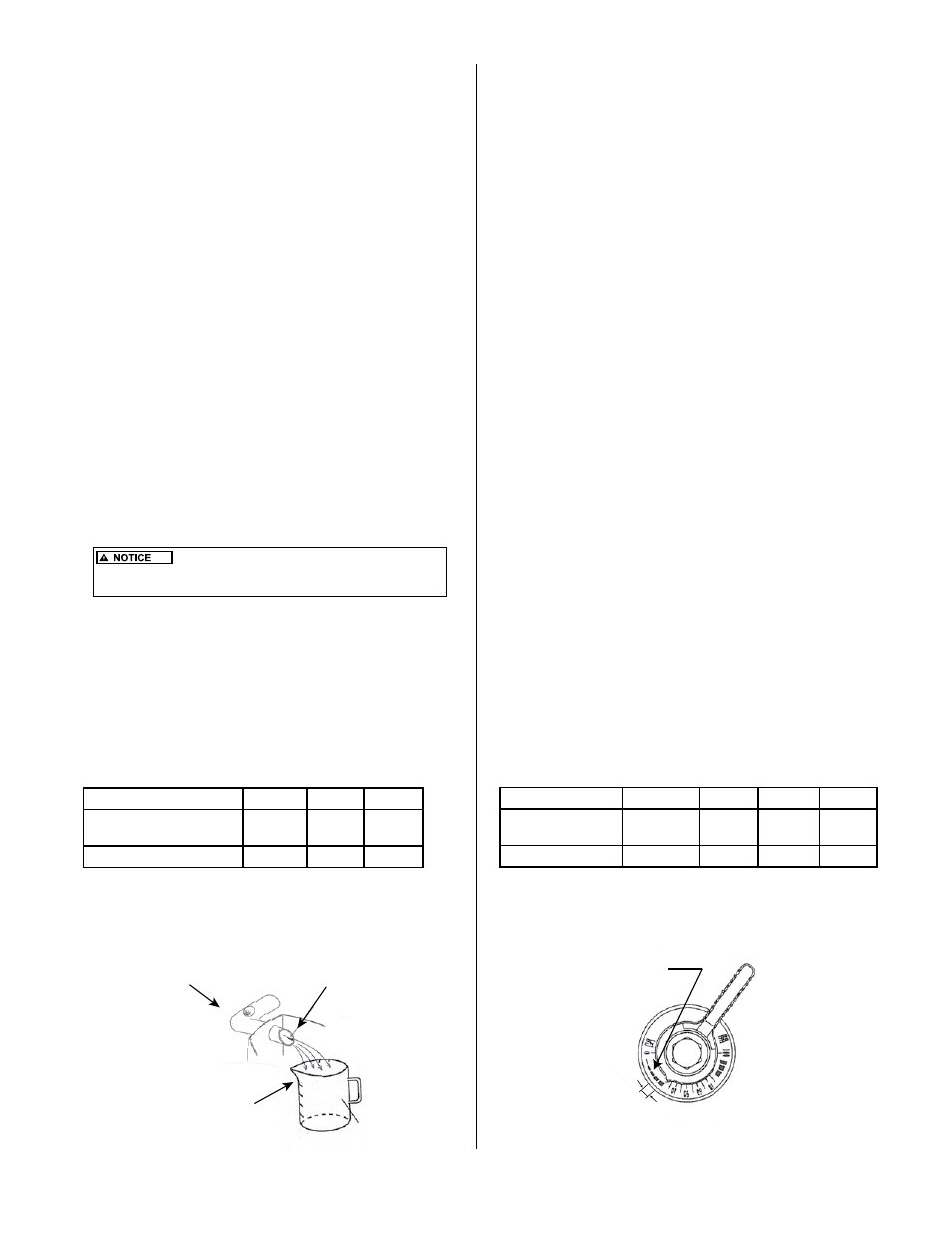

Measuring the flow rate:

• The actual flow rates must be measured to verify flow

after adjustment of the valve and observation at the

pipe end.

• Measure the time in seconds required to fill a 1L

container.

• Compare the time to value ranges in Table 4.

• If necessary, adjust the valve again and collect another

sample to verify the correct flow rates.

In order to prevent plugging of the media in the Aeration

Chamber, the backwash cycle activates at a preset

schedule. If there is no backwash cycle or too short

of a backwash cycle, the unit’s performance will be

adversely affected. Likewise, if the backwash cycle is

too long, performance will be compromised.

The backwash cycle begins at 2:00 AM and lasts for five

minutes. One hour later, another five minute backwash

cycle occurs. Even with these default settings, the waste

water inflow could be too low or too high to optimize

the performance and therefore, must be checked during

each inspection. The backwash initiation time can be

set for any time during a

24-hour period to accomodate unusual water use

patterns. The goal is to set the time when there is no

flow into the unit.

The backwash cycle and sludge transfer from the

Aeration Chamber takes place at the same time.

Verify that the air flow is uniform across the Aeration

Chamber between the two sides during a backwash

cycle. If not, adjust the red backwash valve (3)

accordingly.

Setting the flow rate:

• Switch to a manual backwash cycle by pressing

the pink "Manual Backwash" button on the blower

control pad.

• Set the backwash flow rate by adjusting the gray

sludge transfer valve (4). Use Table 5 to determine

the setting for each Fusion® model.

Measuring the flow rate:

• Measure the actual backwash flow rate at the

outlet of the sludge return pipe in the first chamber

the same way the recirculation flow rate is measured.

• Adjust the gray sludge transfer valve (4) if

necessary to obtain the proper flow.

• Return the blower to normal aeration mode by

pressing the pink button on the blower's control pad.

It is important not to set the flow rate too high

because it can cause excessive agitation within the first chamber

(Sedimentation Chamber). This could result in poor performance.

RECIRCULATION FLOW ADJUSTMENT

BACKWASH FLOW ADJUSTMENT

Table 5 - Backwash Flow Rate Setting

Model

Frequency

ZF450

ZF600

ZF800

Backwash flow rate

(sec/liter)

Twice/day

7-10

5-7

4-6

Valve open (%)

Twice/day

50-55

40-45

40-45

Figure 15 - Flow

Controlling Valve

Figure 14 - Flow

Measurement

Model

ZF450

ZF600

ZF800

Recirculating flow rate

(sec/liter)

29-45

21-32

14-22

Suggested Valve Opening

35-40%

30-35% 30-35%

Table 4 - Recirculation Flow Rates

DOTTED

SCALE

VALVES

SUGGESTED

RANGE

MARKER

CONTAINER

RECIRCULATION OR

BACKWASH PIPE