Pr el im in a ry, Aeration chamber cleaning – Clarus Environmental Fusion Series Treatment Systems 450/600/800 User Manual

Page 14

14

© Copyright 2012. All rights reserved.

PR

EL

IM

IN

A

RY

AERATION CHAMBER CLEANING

1. Aeration

The aeration system must be flushed every maintenance

visit. There are two flushing methods: (A) Air flushing

and (B) Water flushing. Air flushing must be done every

maintenance visit. Water flushing may be done if there is

a sign of clogging in the Aeration Chamber (e.g. abnormal

increase in recirculation flow).

(A) Air flushing procedure:

• Make sure the blower is in the aeration mode.

• Close gray recirculation valve (2) all the way. (0%)

• Rotate blue aeration valve (1) back and forth from the

0% to the 100% position several times to flush.

• Set valves (1) and (2) back to the appropriate positions.

(See Recirculation Flow Adjustment, pg. 10)

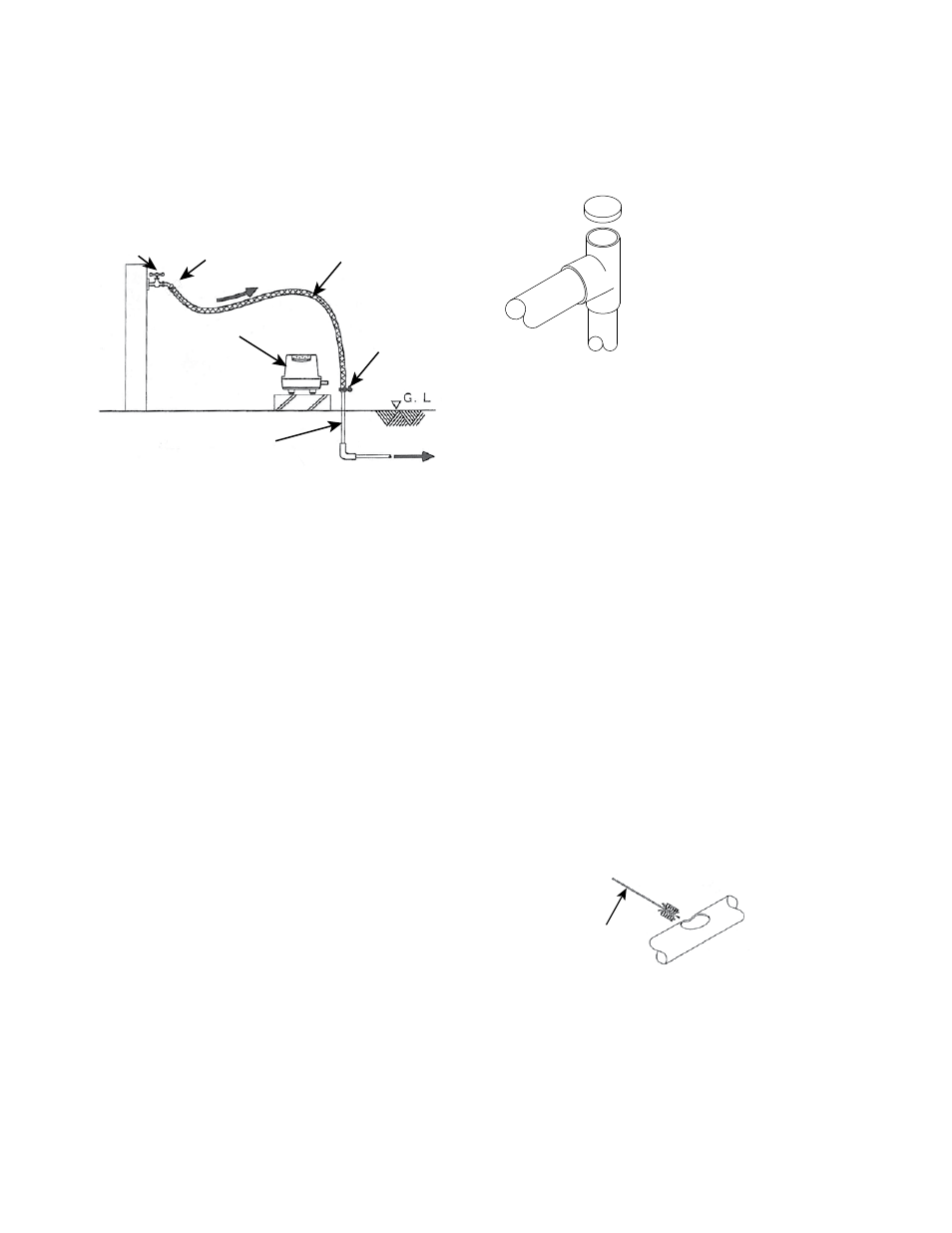

(B) Water flushing procedure: (See Figure 18)

• Make sure the blower is off.

• Close valve (2) all the way.

• Connect a water line to the aeration line as shown in

Fig. 18.

• Gradually open the water faucet and introduce water

into the system.

• Rotate valve (1) back and forth from the 0% to the

100% position several times to flush.

• Turn off the water, remove the water line, and

reconnect the airline to the blower.

• Set valves (1) and (2) back to the appropriate

positions. (See Recirculation Flow Adjustment, pg. 10)

(C) Cleaning the recirculation line:

• Make sure the blower is in the aeration mode. If not,

change the mode by pressing the Manual Backwash

button.

• Open the gray recirculation valve (2) to 100%.

• Flush water through the recirculation line for several

seconds.

• Turn off the recirculation by rotating the gray valve

(2) to 0%.

• Make sure the blower is off. Allow the system to

relax for a few seconds.

• Repeat this cleaning method three times. • A hose or

brush can also be used to clean the recirculation line.

See Figure 20.

• Reset the gray valve (2) to its original position.

2. Backwash

The backwash system must be flushed every maintenance

There are two flushing methods: (A) Air flushing and

(B) Water flushing. Air flushing must be done every

maintenance visit. Water flushing must be done if there

is a sign of clogging in the Aeration Chamber (e.g.

abnormal increase in recirculation flow).

(A) Air flushing procedure:

• Make sure the blower is in the

backwash mode.

• Close the gray sludge transfer

valve (4) all the way.

• Rotate the red backwash valve

(3) back and forth from the 0%

to the 100% position several

times to flush.

• Set valves (3) and (4) back to

FAUCET

BACKFLOW

PREVENTER

WATER

HOSE

CLAMP

TO TREATMENT UNIT

BLOWER

EXISTING

AIR LINE

.

Figure 18

the appropriate positions.

(See Backwash System) (B) Water flushing procedure:

(See Fig. 19)

• Make sure the blower is off.

• Close valve (4) all the way.

• Connect a water line to the backwash airline as shown in

Figure 16.

• Gradually open the water faucet and introduce water into

the system.

• Rotate valve (3) back and forth from the 0% to the 100%

position several times to flush.

• Turn off the water, remove the water line, and reconnect

the airline to the blower.

• Set valves (3) and (4) back to the appropriate positions.

(See Backwash System)

(C) Cleaning the sludge transfer line:

• Make sure that the blower is in the backwash mode. If

not change the mode by pressing Manual Backwash.

• Open the gray sludge transfer valve (4) to 100%.

• Flush water through the sludge transfer line for a few

seconds.

• Repeat this cleaning method three times.

• A hose or brush can also be used to clean the sludge

transfer line. See Figure 20.

• Reset the gray valve (4) to its original position.

• Return the blower to the normal aeration mode. by

pressing Manual Backwash.

3. Foam formation

Make sure there is not an excess amount of foam on the

surface. If excessive foam is present it may indicate high

detergent usage. Meet with owners to inform and educate

them concerning excessive use.

4. Abnormal water level

If the water level exceeds the partition wall, clean the

plastic cage first with a brush, then check for possible

clogging in the filter media section. Clogs may be cleared

by using a manual backwash tool. The manual backwash

tool may also be used to eliminate a clog in the anaerobic

chamber media as well.

Figure 19

BRUSH

Figure 20